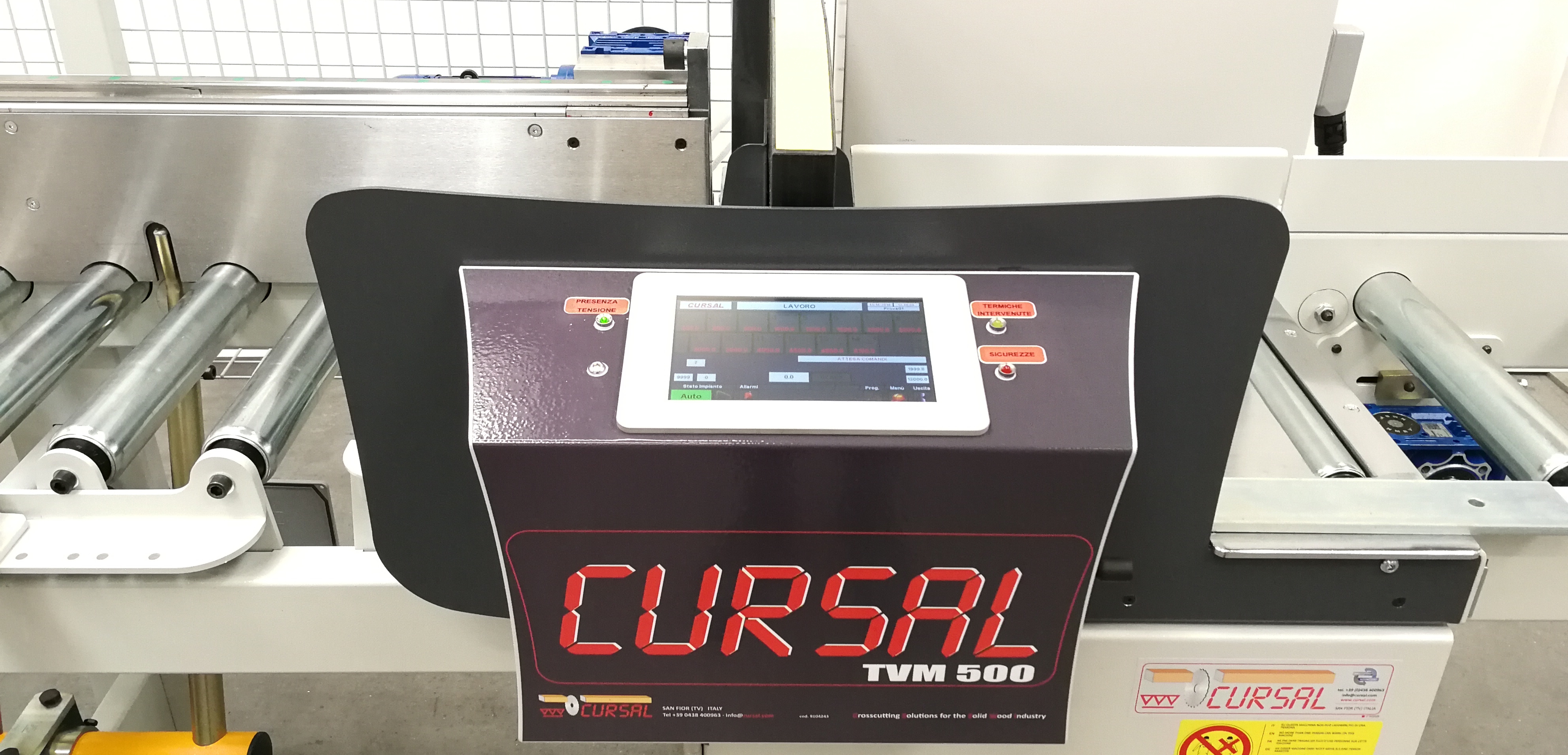

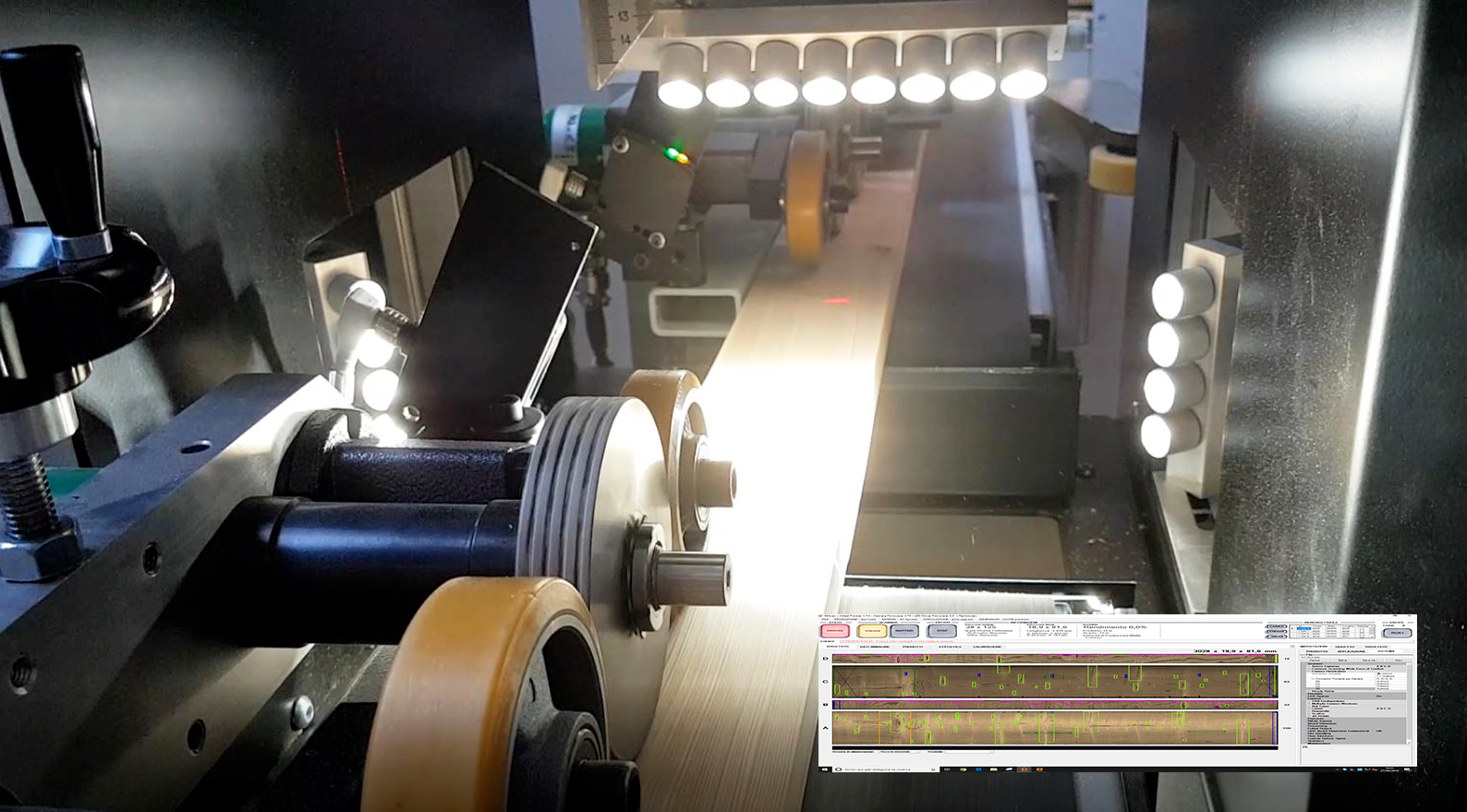

SEMI AUTOMATIC CROSS-CUT SAW TVM 500 BLADE Ø500

TVM 500 – POWER AND FLEXIBILITY FOR ADAPTABLE PROCESSING

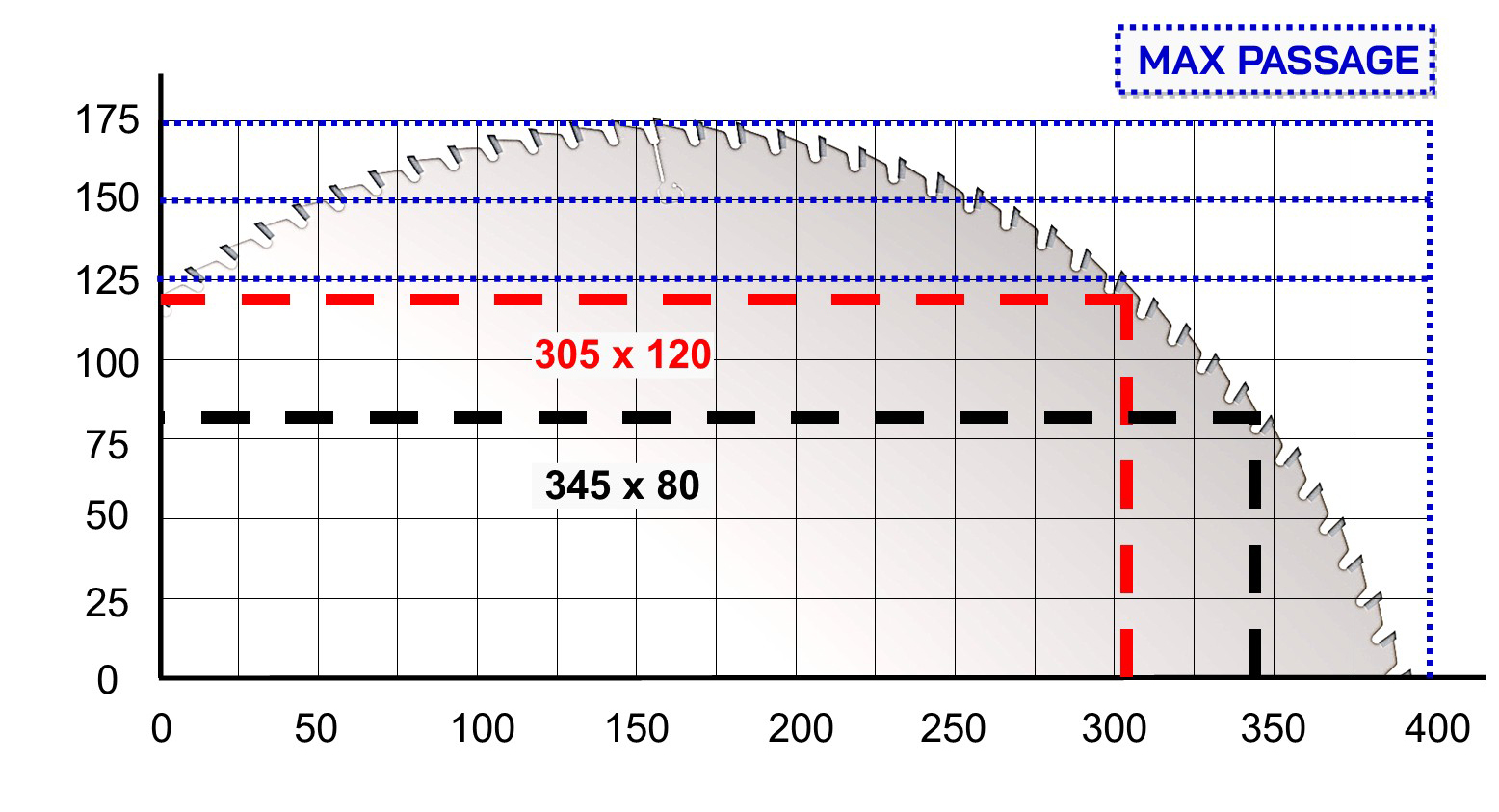

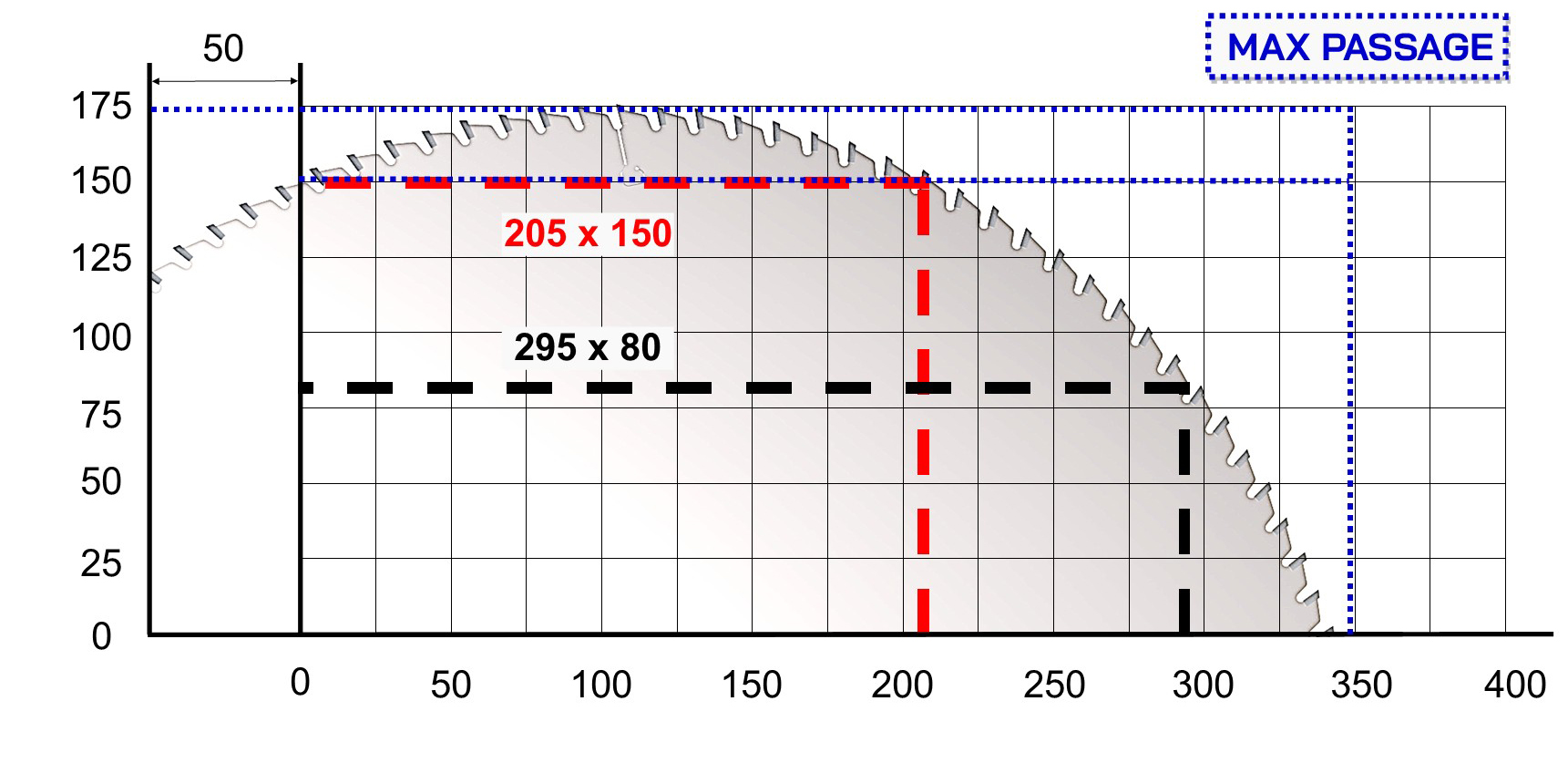

The TVM 500 is a mid-capacity crosscut saw that delivers high performance. It builds on all the features of the TVM 400, with an increased cutting section — ideal for companies managing larger production volumes and requiring both precision and speed.

Perfect for those seeking a balance between power and versatility, it handles both routine and more demanding, variable cutting tasks.

KEY FEATURES

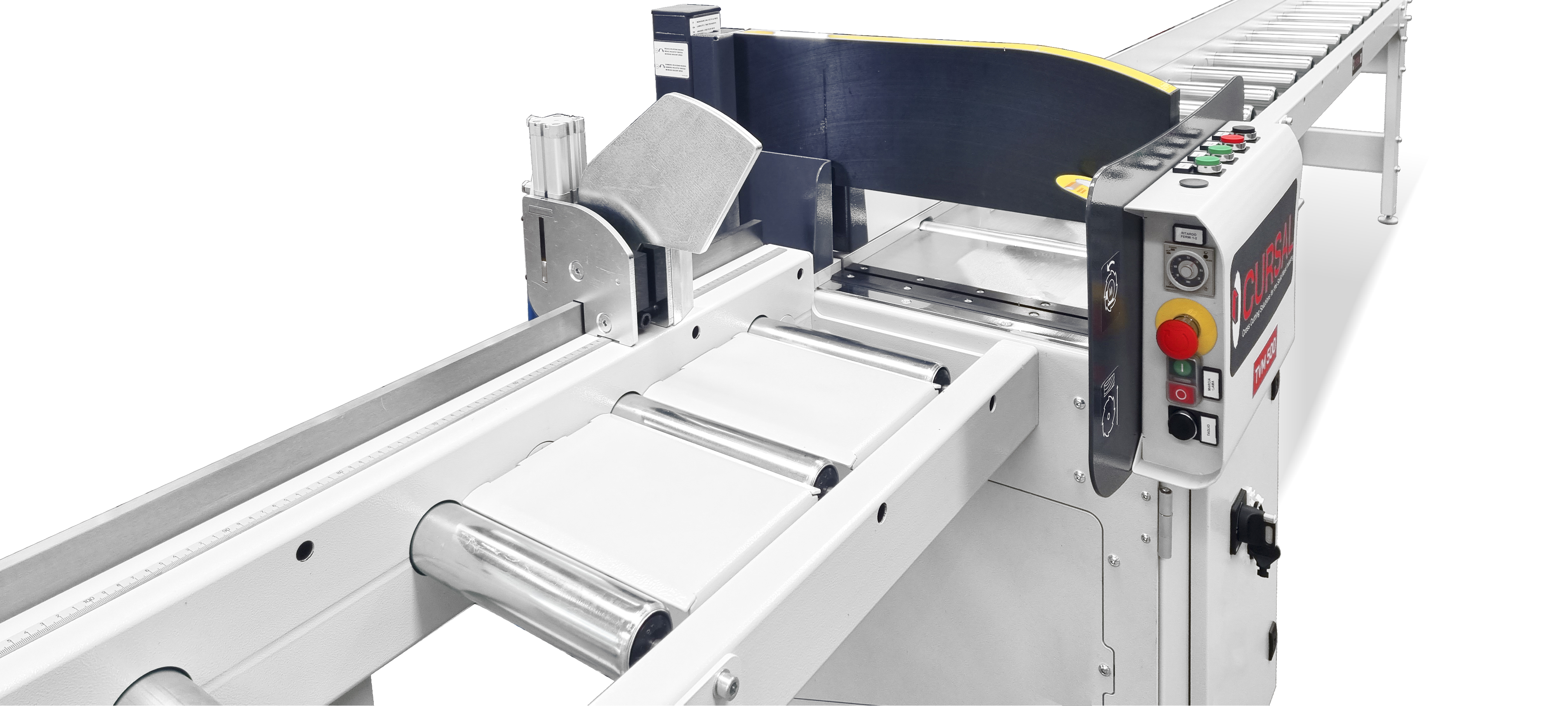

The TVM 500 is designed to process 90% of prism-shaped boards, making it well suited to high-demand sectors such as construction, packaging, and structural component manufacturing. Its vertical reciprocating movement enables faster cutting cycles, delivering clean and precise cuts even on medium-thickness materials.

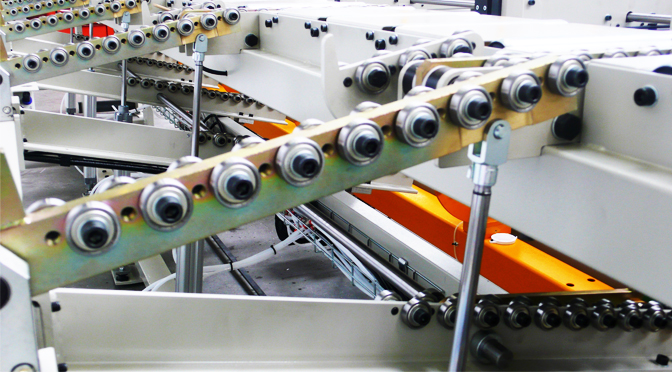

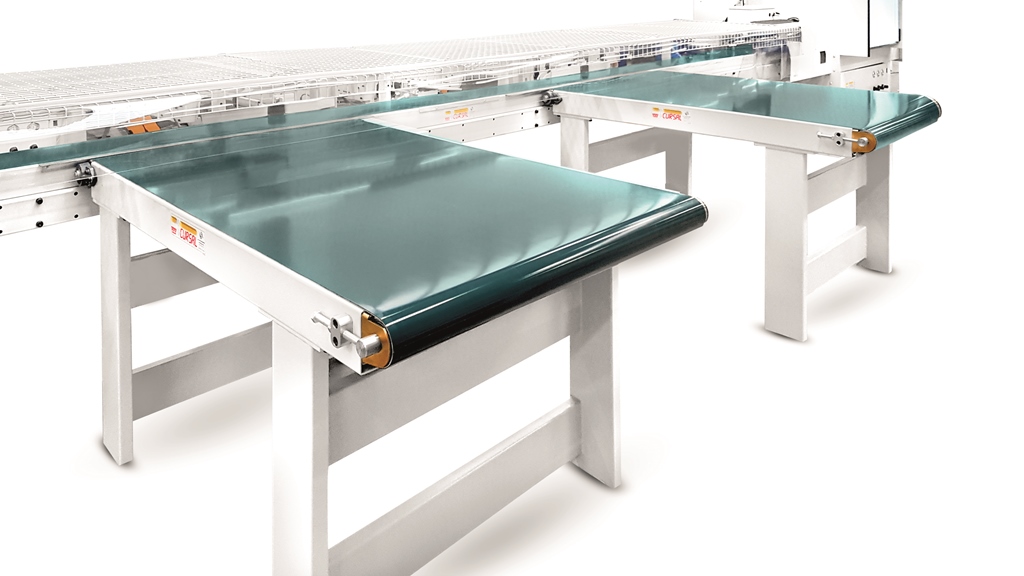

The machine is highly customizable through CURSAL accessories, adapting easily to all types of production.

It can be paired with electro-pneumatic stops for repetitive tasks or with a CNC stop system for greater flexibility in length variations. Integration with advanced exhaust systems further streamlines the workflow.

STRENGTHS

Production versatility: The TVM 500 is ideal for a wide range of materials, from solid wood to semi-finished components and more complex substrates.

High flexibility in size changeover: thanks to numerical control systems or electro-pneumatic stops, the machine easily adapts to large-scale production or projects requiring highly variable cuts.

The TVM 500 combines power, flexibility, and precision — making it the ideal choice for those in need of a high-performance crosscut saw, without compromising on customization.

TVM 500 – POWER, FLEXIBILITY, AND INTEGRATION FOR MID-HIGH PRODUCTION

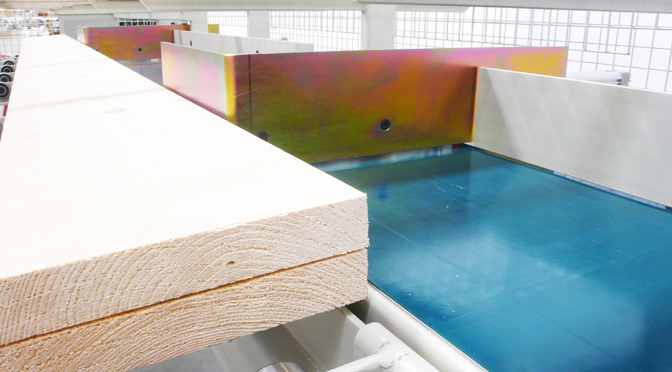

The TVM 500 is ideal for edged boards in sectors such as construction, packaging, and structural manufacturing.

With CURSAL’s customization options, it easily adapts to any production setup.

The numerically controlled stop is especially recommended for these sectors, as it provides greater flexibility in size management.

STRENGTHS

Easy integration: designed for seamless integration into existing production lines, the TVM 500 is compatible with a wide range of accessories and minimizes maintenance

requirements through a wear-reducing design.

Increased productivity: its cutting speed and precision boost productivity, reducing downtime and improving workflow across sectors.

APPLICATION SECTORS

Packaging sector for medium batch custom jobs: ideal for the production of pallets, packaging, and other lightweight products, yet effective also on thicker materials.

Construction: excellent for cutting doors, frames, and skirting boards, handling both high-volume and precision-focused tasks.

Structures and semi-finished products: perfect for producing laminated timber, slats, and other wooden structures used in furniture and industrial components.

CUSTOMIZATION AND INNOVATION

The TVM 500 is an innovative, adaptable machine that can be customized with a wide range of CURSAL accessories to meet any specific need.

A powerful, versatile solution ready to tackle demanding production challenges.