CROSSCUT SAWS – OPTIMIZING PUSH-FEED SYSTEMS FOR ANGULAR CUT – TRGSI BLADE Ø550

TRGSI 550 – Optimized Angular Cutting for Any Production Line

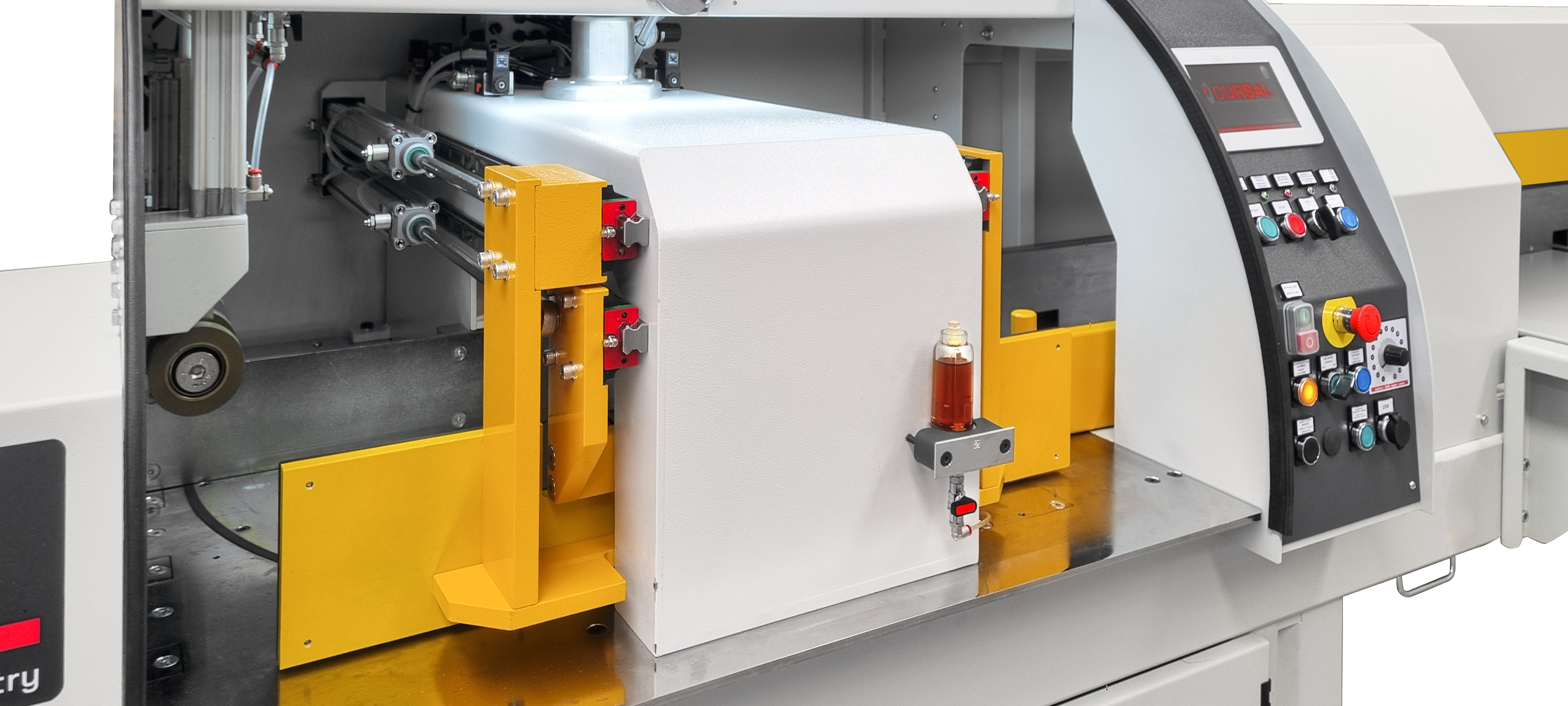

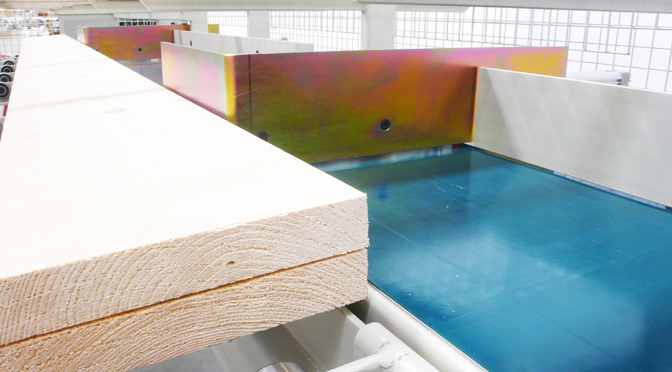

The TRGSI 550 is a high-productivity angular crosscut saw, designed for programmed or optimized cuts on single boards or board packs, at 90° or inclined angles.

Engineered to suit both advanced artisan environments and fully automated production lines, it combines a robust structure, high-end components, and an intuitive control interface.

The machine features a high-rigidity monoblock frame integrating all key components into a single structure, streamlining both installation and relocation while ensuring consistent accuracy, even in demanding cycles. Its compact footprint allows easy integration into existing layouts while ensuring maximum durability.

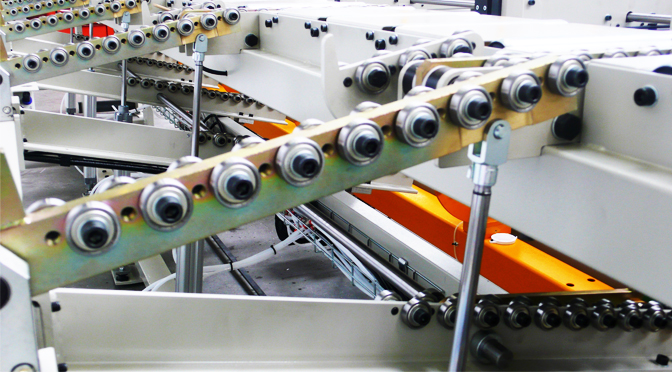

The Cursal CNC pusher, equipped with Brushless motors and a dual-carriage system on ball-bearing linear guides, ensures rapid feed rates up to 250 m/min and smooth handling even with delicate materials.

The synchronized blocking system—positioned before and after the saw blade—maintains precise alignment and constant cutting angles, making the TRGSI 550 suitable for a wide range of workpieces: single boards, packets, semi-finished parts, and treated wood.

The CNC software enables flexible creation and management of complex cutting plans, with full control over every parameter.

Fast data loading via USB or Ethernet, coupled with defects removal optimization functions, ensures high efficiency and precision, even for mixed production.

Designed for sectors such as packaging, windows and doors, and custom furniture, the TRGSI 550 delivers high performance and versatility—even in high-volume manufacturing.

It can be equipped with automatic drilling units (up to 18 bits) and high-definition printers, enabling the production of fully processed semi-finished components for a wide variety of applications.

Crosscut Saws for Angular Cuts with Programmed or Optimized Dimensions

The TRGSI, TRGSI AP, and TRGSI OL are angular crosscut saws designed for sequential cutting of trimmed boards, ideal for applications such as packaging, where continuous and accurate cuts are required without defect selection.

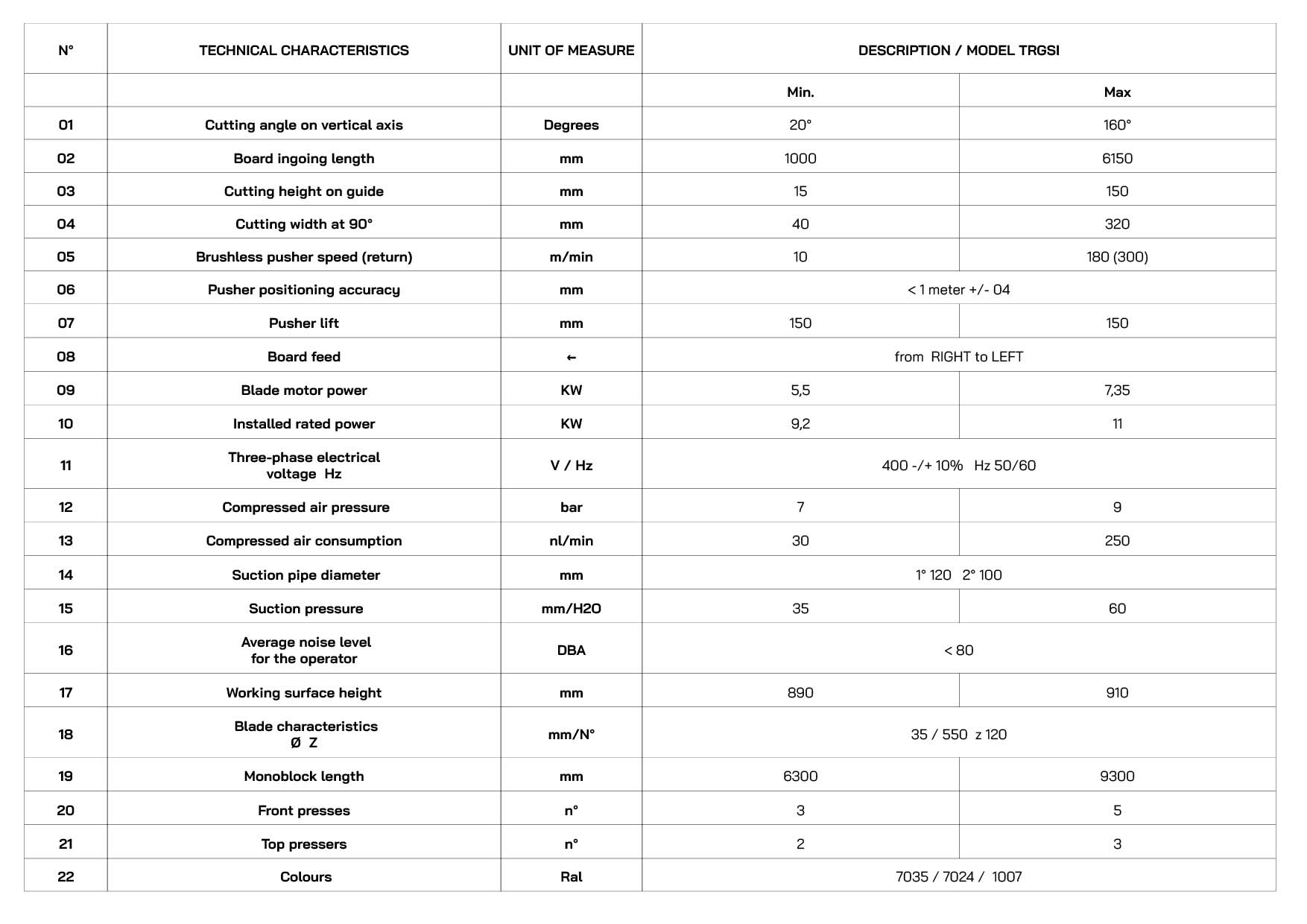

The TRGSI handles boards automatically from 1000 to 6150 mm in length and thicknesses from 15 to 150 mm.

Its CNC system ensures smooth feed speeds up to 180 m/min, meanwhile, the touchscreen software allows management of multiple folders, each with 15 cutting programs. Equipped with Brushless motors and ball-bearing linear guides, it offers speed and precision, making it ideal for standardized production environments.

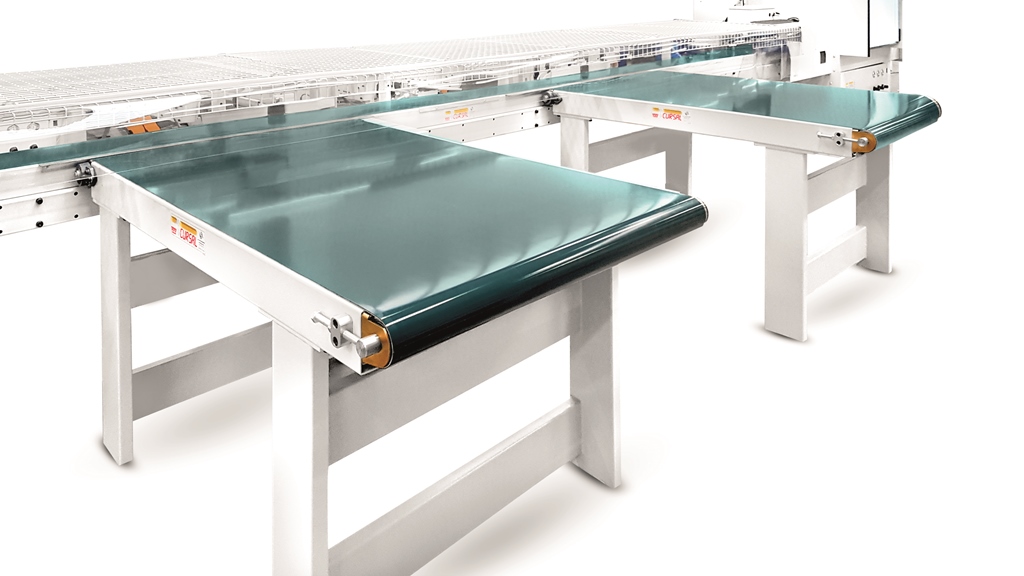

The TRGSI AP adds enhanced material handling features, including a pneumatically lifted pusher and dedicated accessories such as chain infeed systems and unloading conveyors with multiple ejection stations.

It is suited for straight boards with constant width and is optimized for automated production lines.

The TRGSI OL, on the other hand, is tailored for operations requiring length optimization.

The Cursal Manager software manages up to 1,400 dimensions and applies multiple cutting rules to minimize waste.

Offers a perfect balance of flexibility, accuracy, and process control—all while maintaining high operating speeds.

All models can be equipped with automatic drilling units (up to 18 bits) and high-definition printers, enabling the production of fully processed semi-finished components to meet a wide range of production needs.

TRGSI INTEGRATED INTELLIGENT DRILLING SYSTEM

From design to perfect hole, without interruptions:

The integrated Cursal system optimizes each board with speed, CNC control, and complete flexibility

TRGSI E – Advanced Optimization of Lengths and

Defects

The TRGSI E is a high-performance angular crosscut saw designed to optimize the cutting of boards with visible defects, minimizing waste.

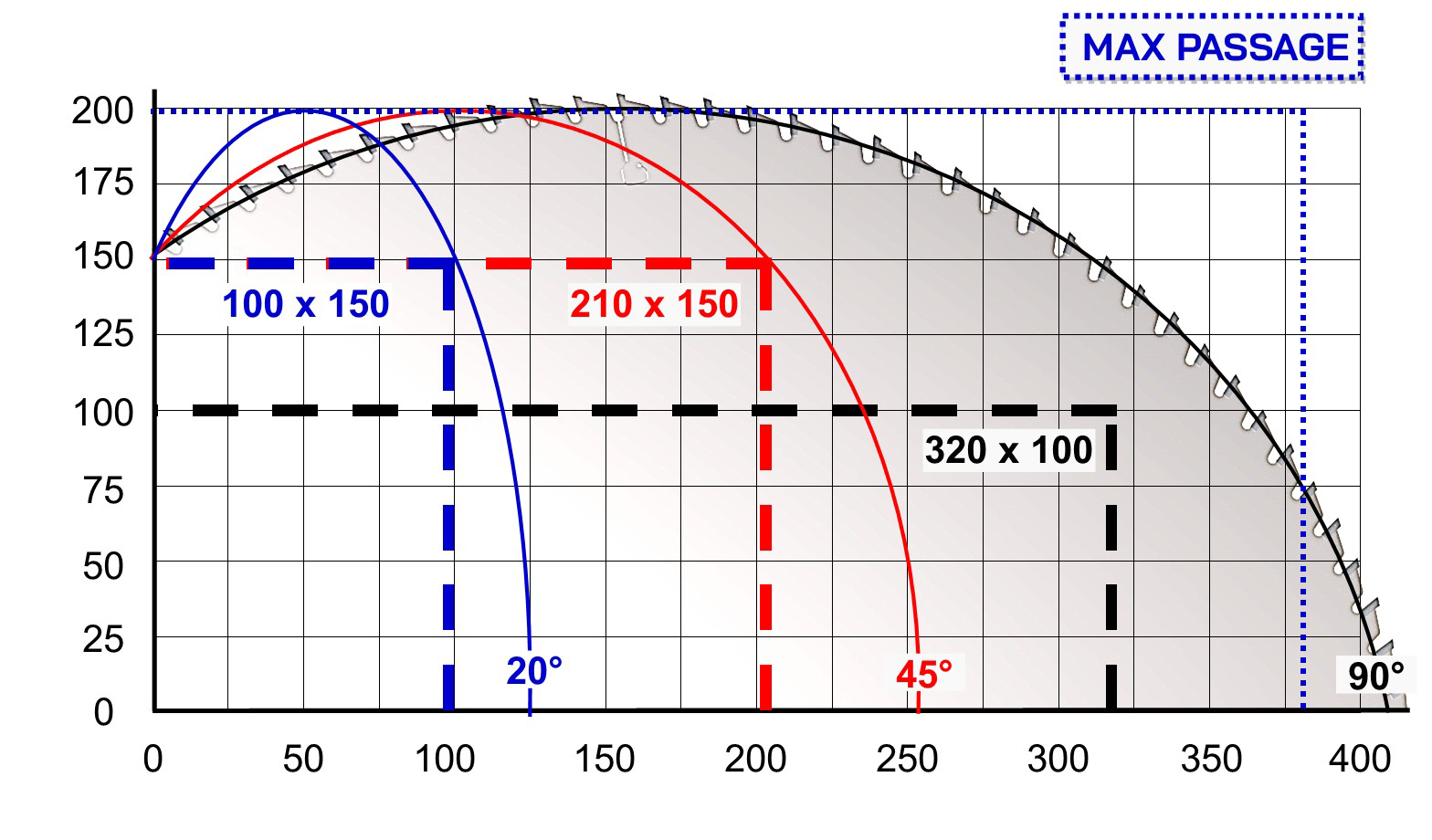

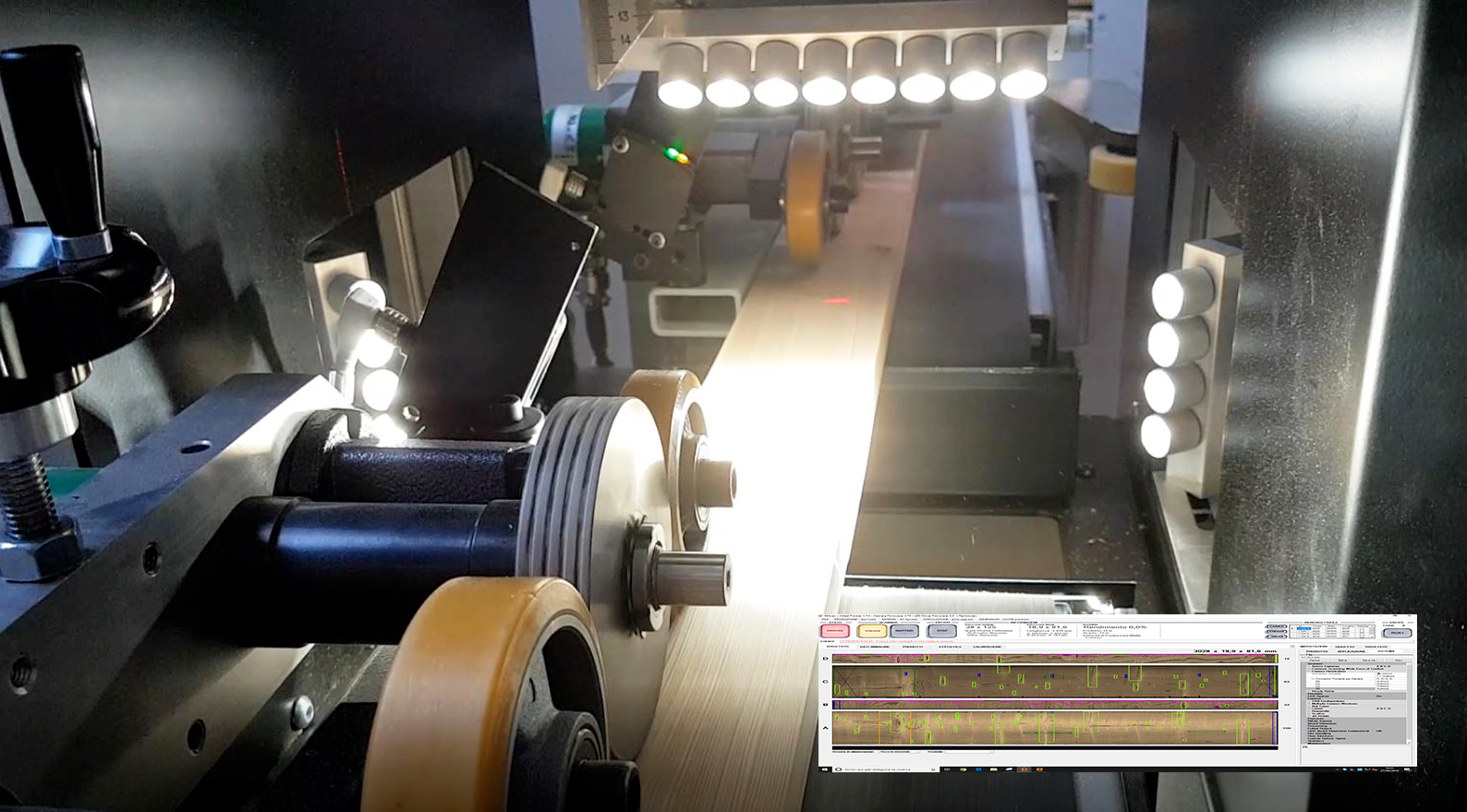

Thanks to an integrated camera and Cursal Manager software, it automatically identifies marked imperfections – with chalk – and manages up to 1,400 different measurements, including inclined cuts ranging from 20° to 160°.

The entire process can be remotely controlled, ensuring maximum efficiency even with heterogeneous materials.

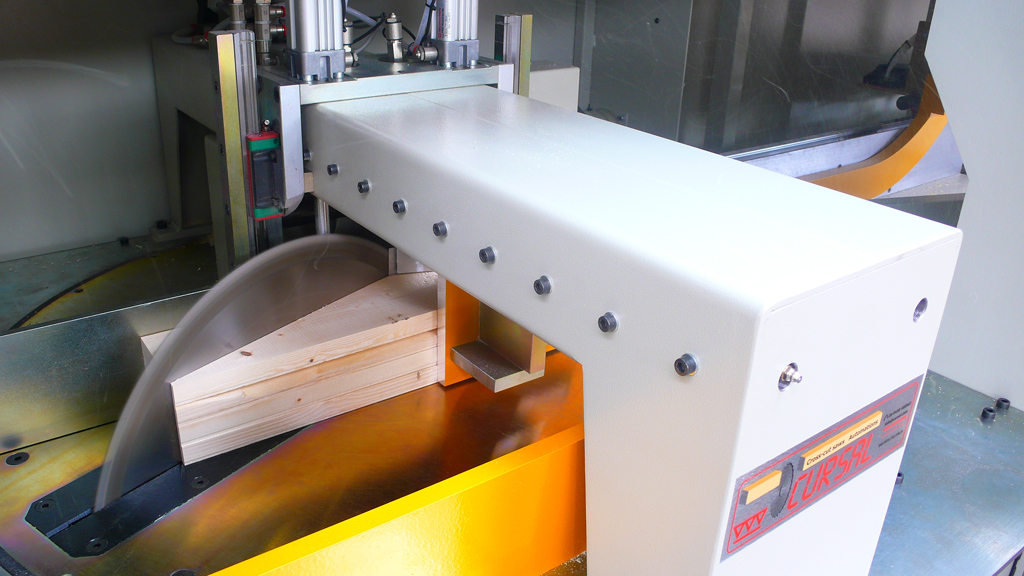

An additional strength is the ability to integrate a fully automated drilling system that operates in synchronization with the crosscut saw.

After optical analysis, the software processes the cutting and drilling plan in real-time, avoiding machine downtimes and improving productivity.

The drilling module, available in configurations of 1, or 5 spindles, is highly configurable and ensures precision even in complex productions, thanks to its structure with ball-bearing linear guides and Brushless motors.

Piece stability is guaranteed by an alignment system with independent axes and pneumatic movement controlled by CNC, preventing micro-shifts during drilling.

The system is managed by an industrial PC with a Windows interface, equipped with software compatible with the main business management systems and complete with tools for remote assistance or autonomous operation via scalable packages.

The TRGSI E is the ideal solution for those needing a versatile, integrable machine capable of optimizing every stage of the process, from cutting to drilling.

It includes all the features present in the other models of the series.