ROLLERS FEEDING OPTIMIZING CROSSCUT SAW – TROA BLADE Ø 550

ROLLER FEED: THE STRONG LINK IN THE SAWMILL, IN-LINE WITH LOG SAWS AND MULTIBLADE SYSTEMS

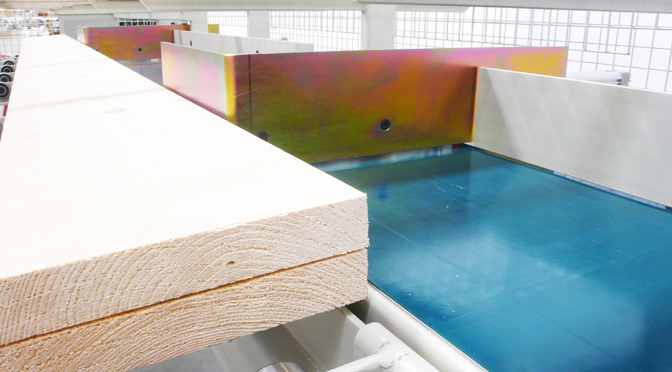

TROA and TROE series are advanced solutions for automatic and optimized crosscutting, specifically designed for the sawmill industry.

With nearly 50 years of experience, Cursal has developed this series to compete in speed with the fastest log saws, including bidirectional ones—reducing processing cycles, optimizing material handling, and minimizing waste.

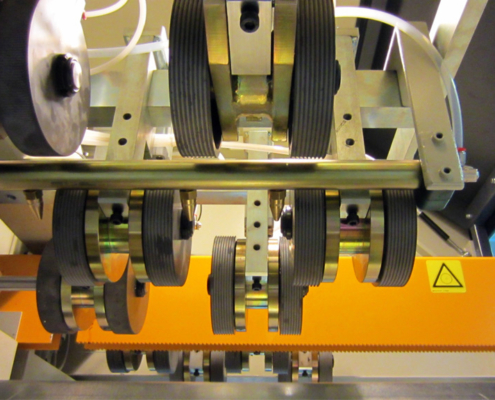

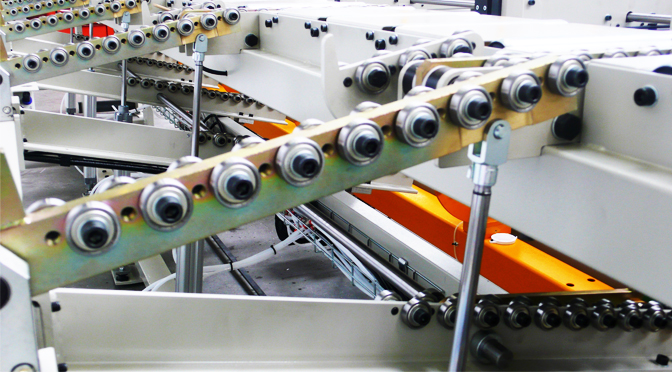

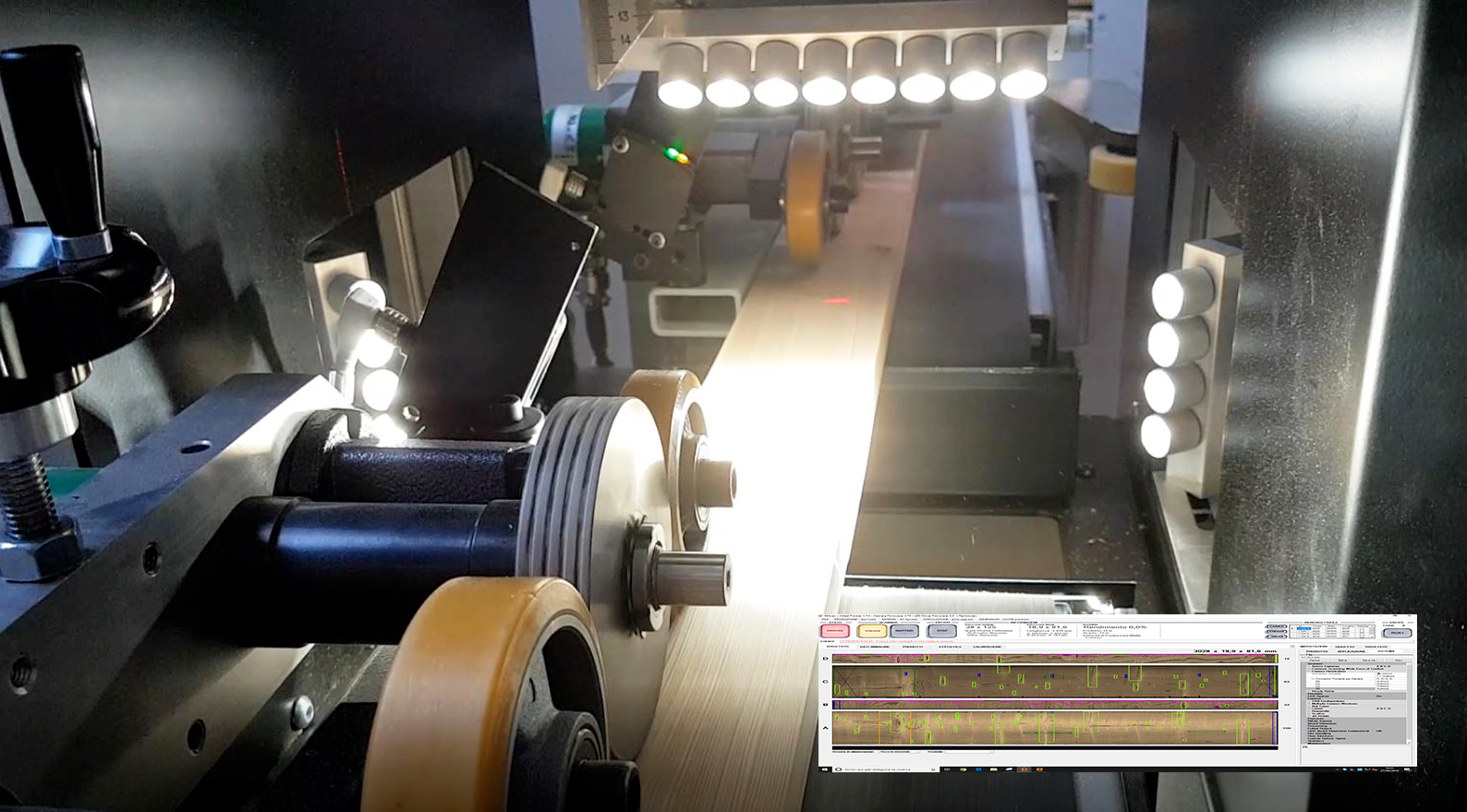

These machines are distinguished by the pulling system with rollers and nitrided wheels with independent pressure.

Engineered to withstand the toughest conditions—such as processing of hard, wet, or frozen wood—and also suitable for dried, warped, or cracked boards along their entire length, the TROA and TROE are built on a rugged frame designed to handle such challenges while ensuring long-term reliability.

The roller and toothed wheel feed system is the key strength of these machines.

Unlike push-feed positioning systems, CNC-controlled roller traction guarantees higher speeds, even with irregular materials, while maintaining continuous operation.

The machines are equipped with a heavy, welded and CNC-machined carpentry structure.

The wear parts are easily inspected, ensuring simple and long-lasting maintenance.

TROA and TROE series offer high-speed feed motion, powered by Brushless motors.

Feed rates reach up to 110–120 m/min, and blade motors from 15 to 20 HP are equipped with self-braking systems, delivering powerful, precise cuts. They also include an automatic tension release cycle for boards with internal stress—capable of stopping even the most powerful systems—offering a unique Cursal solution.

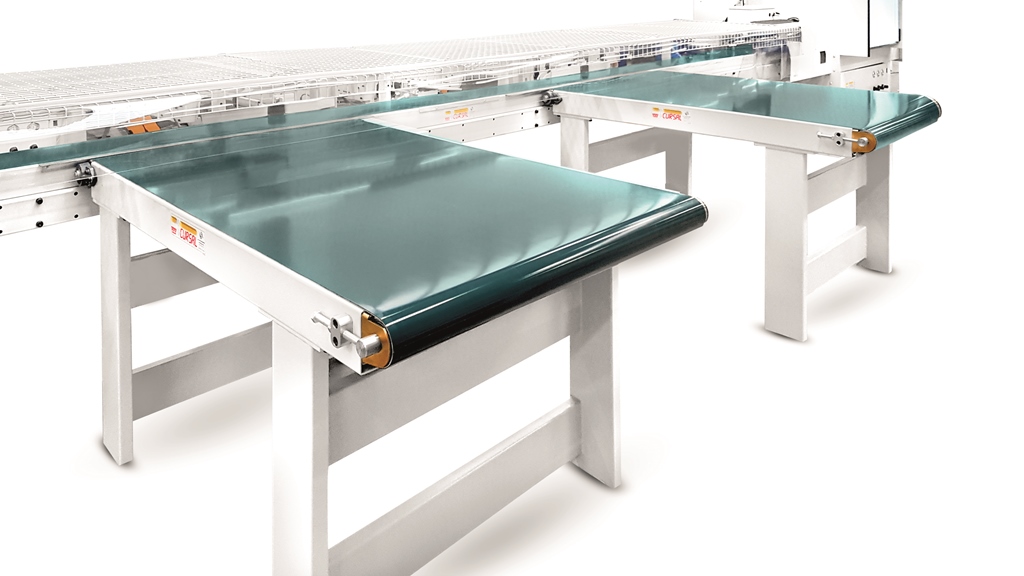

To complete the production line, many customers integrate TRVL cross-cut saws, the ideal choice for converting bulky waste pieces from multiblade machines into ready-to-use firewood for the end user.

The TROA and TROE are designed to offer consistent performance, safety, and durability—establishing themselves as a benchmark for modern sawmills demanding robust, high-performance cutting systems.

FULLY AUTOMATIC TROA FOR SEQUENTIAL LENGTH CUTTING

TROA – Functional Efficiency – Cut-to-Length – High Speed – Continuous Operation

The TROA line is ideal for those who need to process large volumes quickly while maintaining high performance and continuous operation.

With a capacity of up to 22 cuts per minute, it is perfectly suited for processing all types of wood—even under harsher conditions.

Available in various configurations, the TROA serie is suitable for a wide range of industrial applications, from solid wood furniture components to semi-finished products for packaging and pallets.

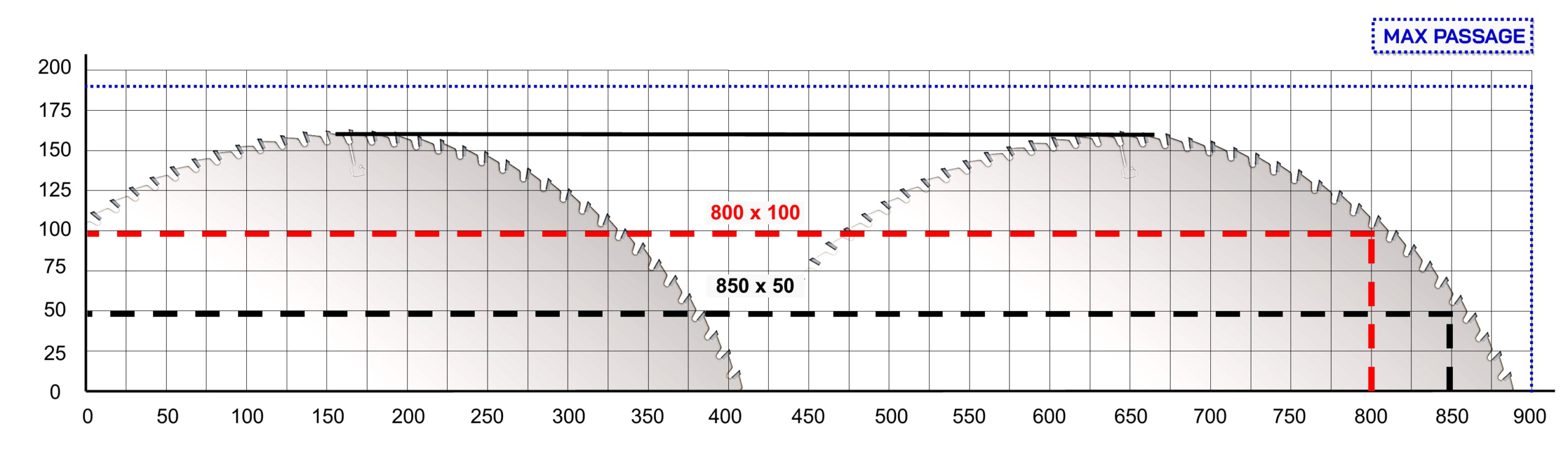

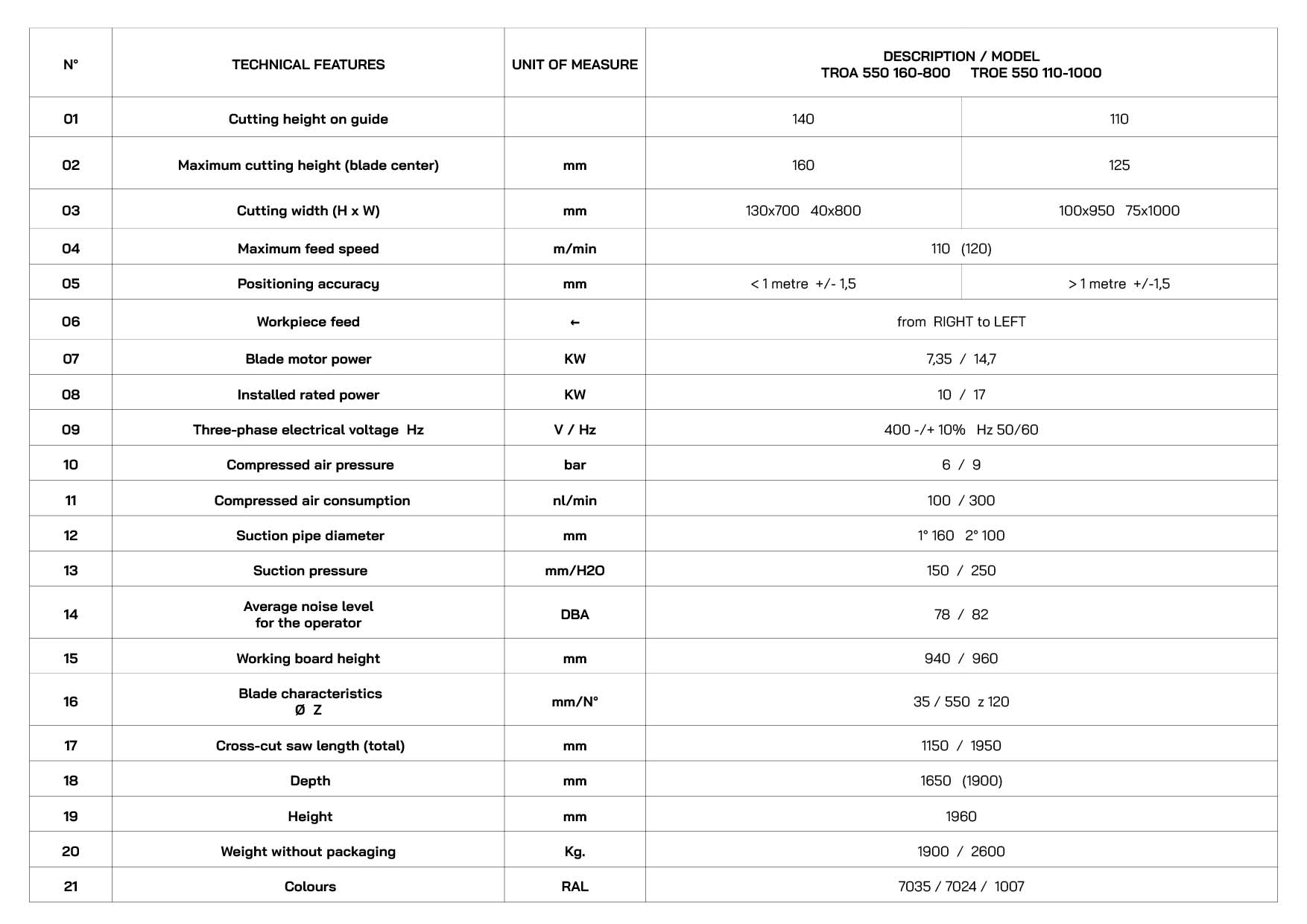

TROA 550-160-800 HS – Heavy-Duty Packaging and Multiblade Pre-Cutting Specialist

Designed for unedged boards and irregular materials, this version handles thicknesses up to 155 mm with variable feed motion, ensuring high precision even at speeds of 110 m/min.

Key Features:

Perfect integration in log saw, multiblade, or finger-jointing lines

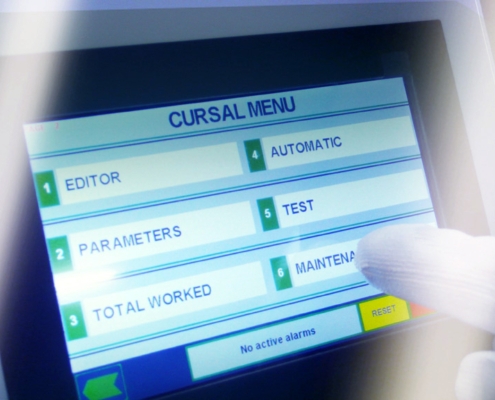

Crosscutting managed via CN touchscreen with program-based cutting at board entry and final optimization to maximize yield from boards of varying lengths

Automatic waste ejection and detection of tilted boards

Customizable with USB/Ethernet connectivity, Excel data export, and programmable cutting cycles

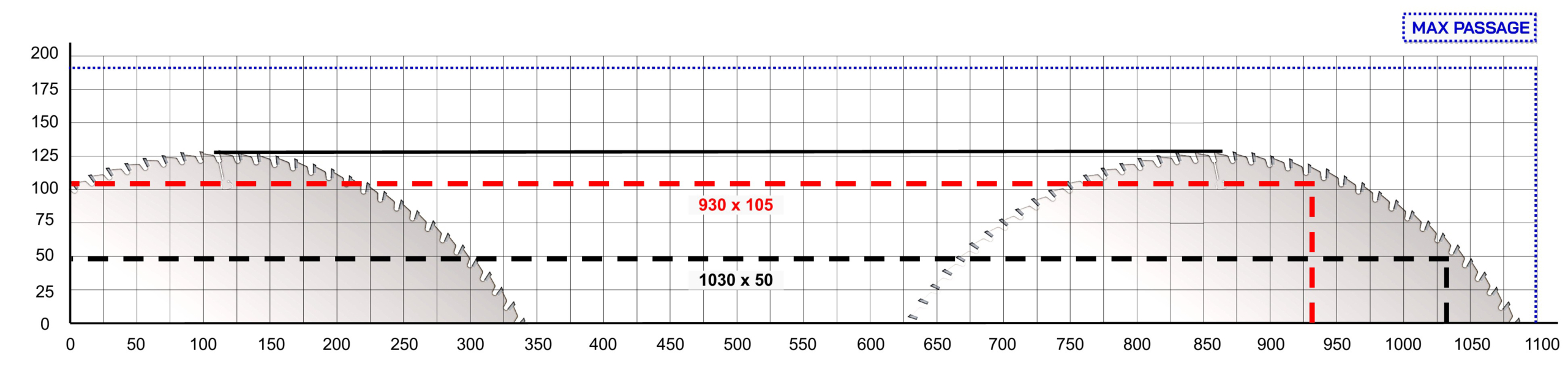

TROA 550-110-1000 – Excellence on Difficult Woods

Ideal for hardwoods such as oak, beech, and teak, this model combines reliability and versatility.

Featuring motorized adjustment of the upper carriage and a 125 mm blade stroke, it allows processing of a wide range of thicknesses and widths exceeding one meter.

When working with such boards, the 18 independently controlled and partially CNC-motorized pressure wheels are essential to prevent feeding errors—especially on boards with longitudinal cracks.

The intuitive interface manages up to 15 cutting programs, each with 90 customizable lengths.

Main Applications:

– components for solid wood furniture

– semi-finished parts for joints and interlocking systems

– hybrid solutions combining manual and automatic handling