CROSSCUT SAWS – OPTIMIZING PUSH-FEED SYSTEMS – TRSI BLADE Ø600

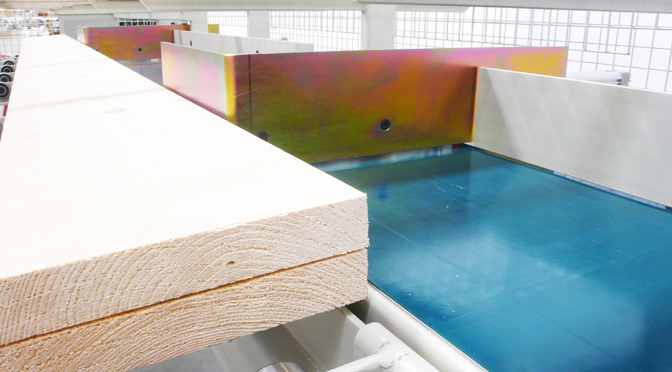

THE IDEAL SOLUTION FOR BEECH SAWMILLS

Thanks to its generous cutting width, this machine is particularly well-suited for processing beech boards, which typically feature constant thickness and variable widths.

Why is the push-feed system the most widely used?

The answer is simple: uncompromising versatility.

The TRSI 600 offers the ideal combination of robust construction, cutting precision, and adaptability, meeting the needs of all sectors involved in solid wood processing and its derivatives.

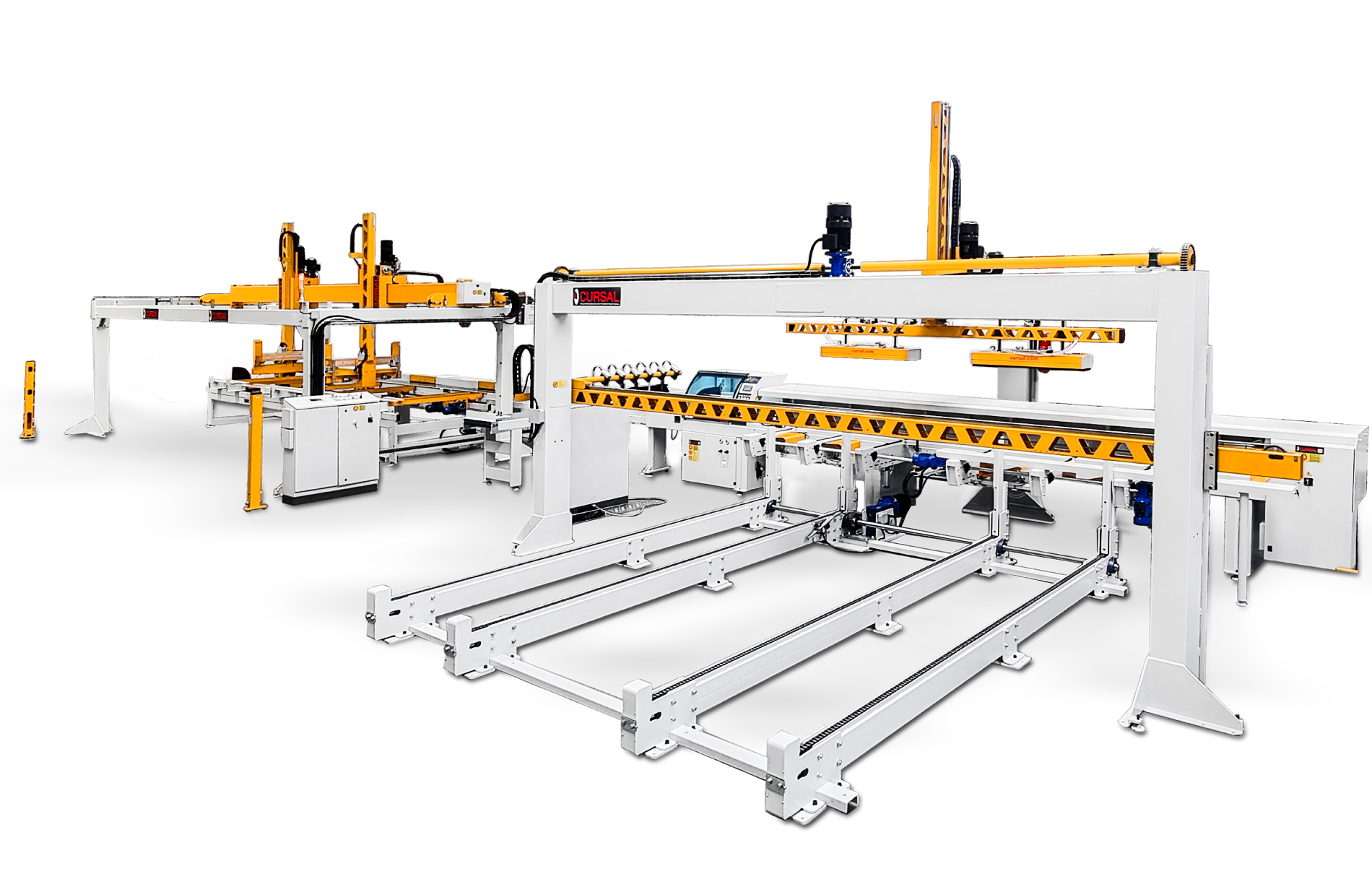

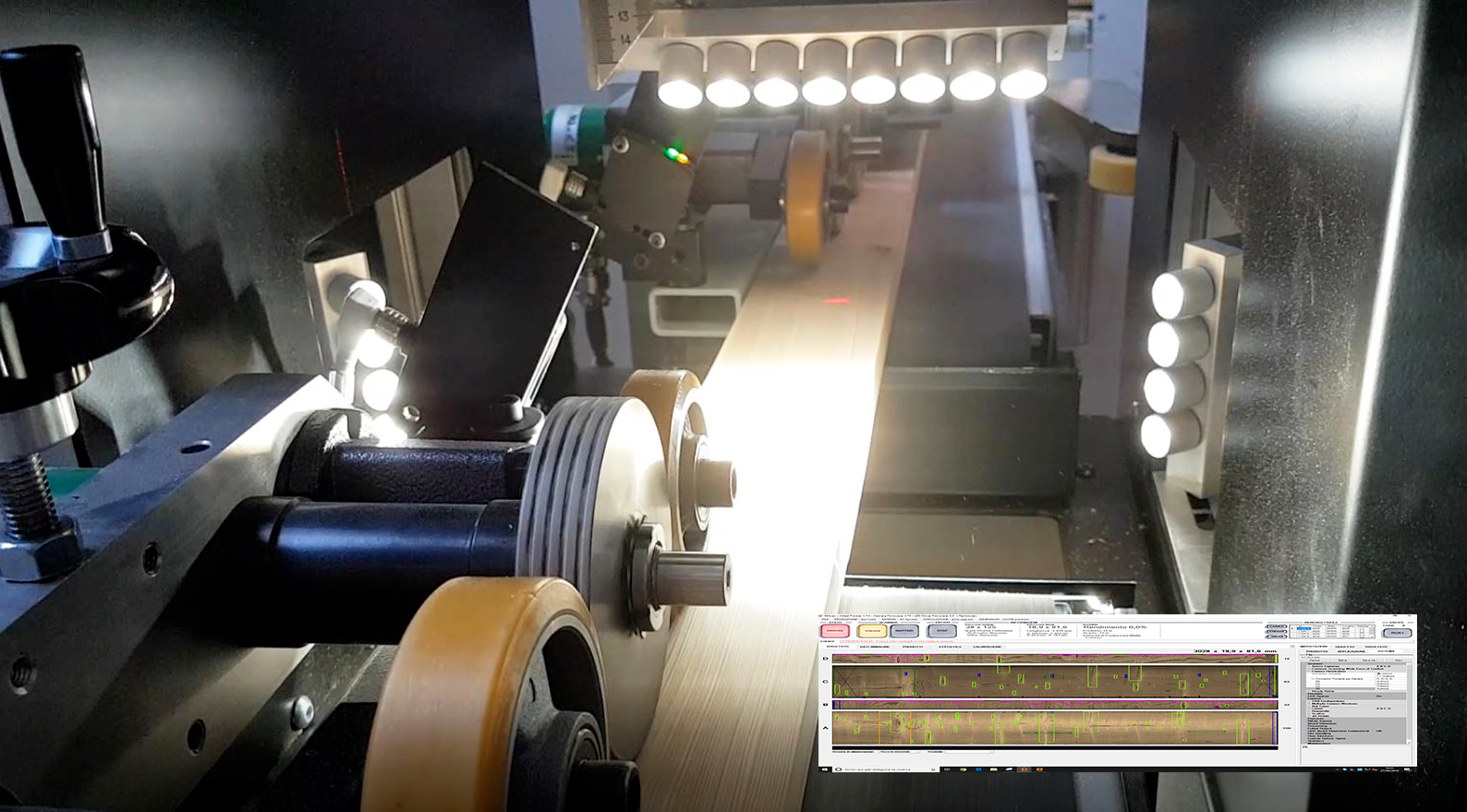

Compact structure, industrial core The TRSI Ø600 stands out with its modular monoblock frame—a solution pioneered by Cursal and since imitated by many—providing maximum stability and resistance to deformation.

This ensures long-term durability, ease of installation, and seamless integration into automated production lines. Its compact footprint allows for space optimization, delivering more technology in less space.

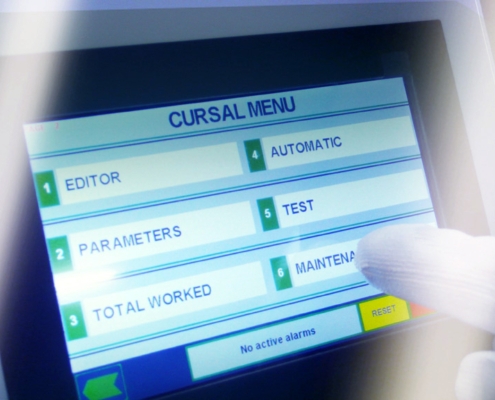

One machine, endless possibilities With its versatile mechanical and software configurations, the TRSI Ø600 is ideal for programmed cutting and defect-optimized cutting.

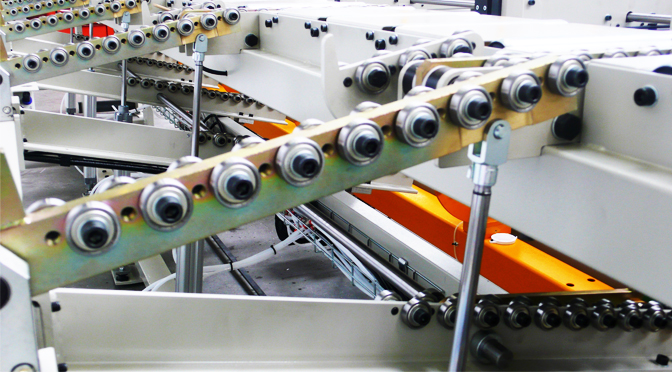

Details that make the difference Features include a pneumatically lifting pusher, blade pressor on linear-guide, aligners with integrated blower and oil-bath friction rubber wheels ensuring constant thrust.

The machine can be equipped with customizable accessories, as well as automated loading, code marking, and intelligent unloading systems.

TRSI 600: Modularity, Automation, and Flexibility for the Packaging Sector

Cursal is the benchmark in the packaging sector, which accounts for over 65% of our customer base.

We offer modular and scalable solutions, guiding clients through a path of progressive automation, from the basic configuration to a fully automated system.

The system starts with a ready-to-use standard configuration, ensuring immediate continuity and productivity right from installation:

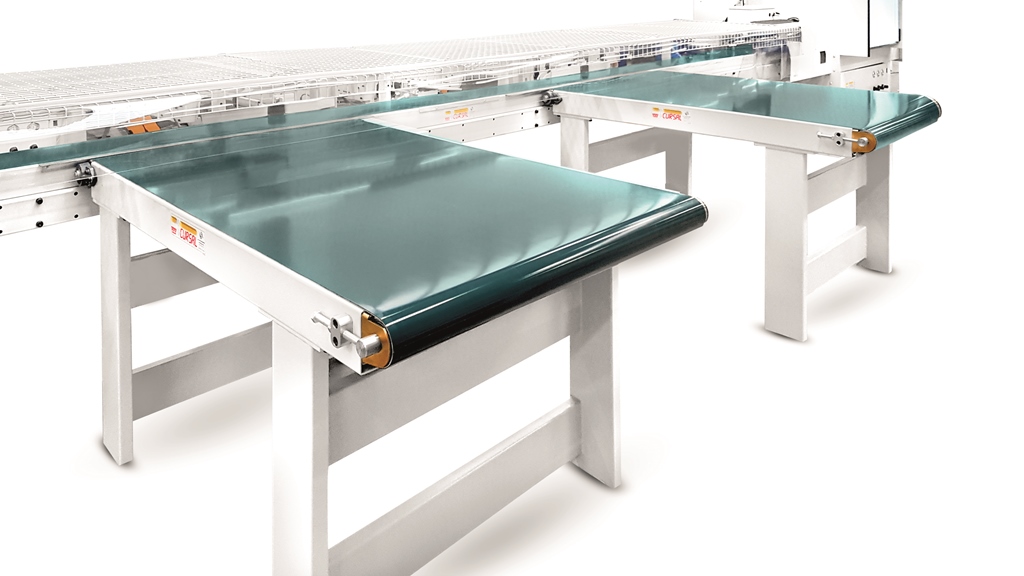

CALS infeed chains to create an orderly buffer

Outfeed ejectors for packets of semi-finished products

Collection via idle roller conveyors for safe and smooth material handling

The configuration can be expanded with automatic loading and unloading systems, addressing the growing demand for labor input and high-throughput productivity.

Sequential Cutting, Maximum Flexibility

Our TRSI series crosscut saws are ideal for fast, accurate sequential cutting.