CROSSCUT SAWS – OPTIMIZING PUSH-FEED SYSTEMS – TRSI BLADE Ø500

Why is the push-feed system the most widely used?

The answer is simple: uncompromising versatility.

The TRSI Ø500 offers the ideal combination of robust construction, cutting precision, and adaptability, meeting the needs of all sectors involved in solid wood processing and its derivatives.

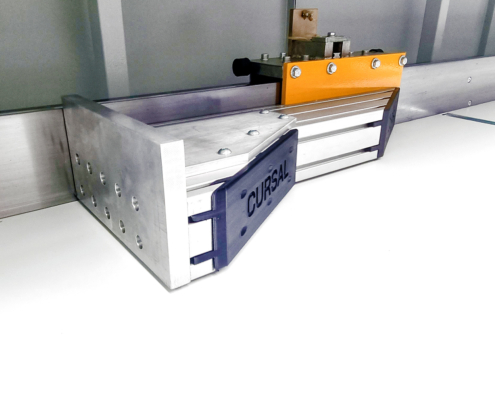

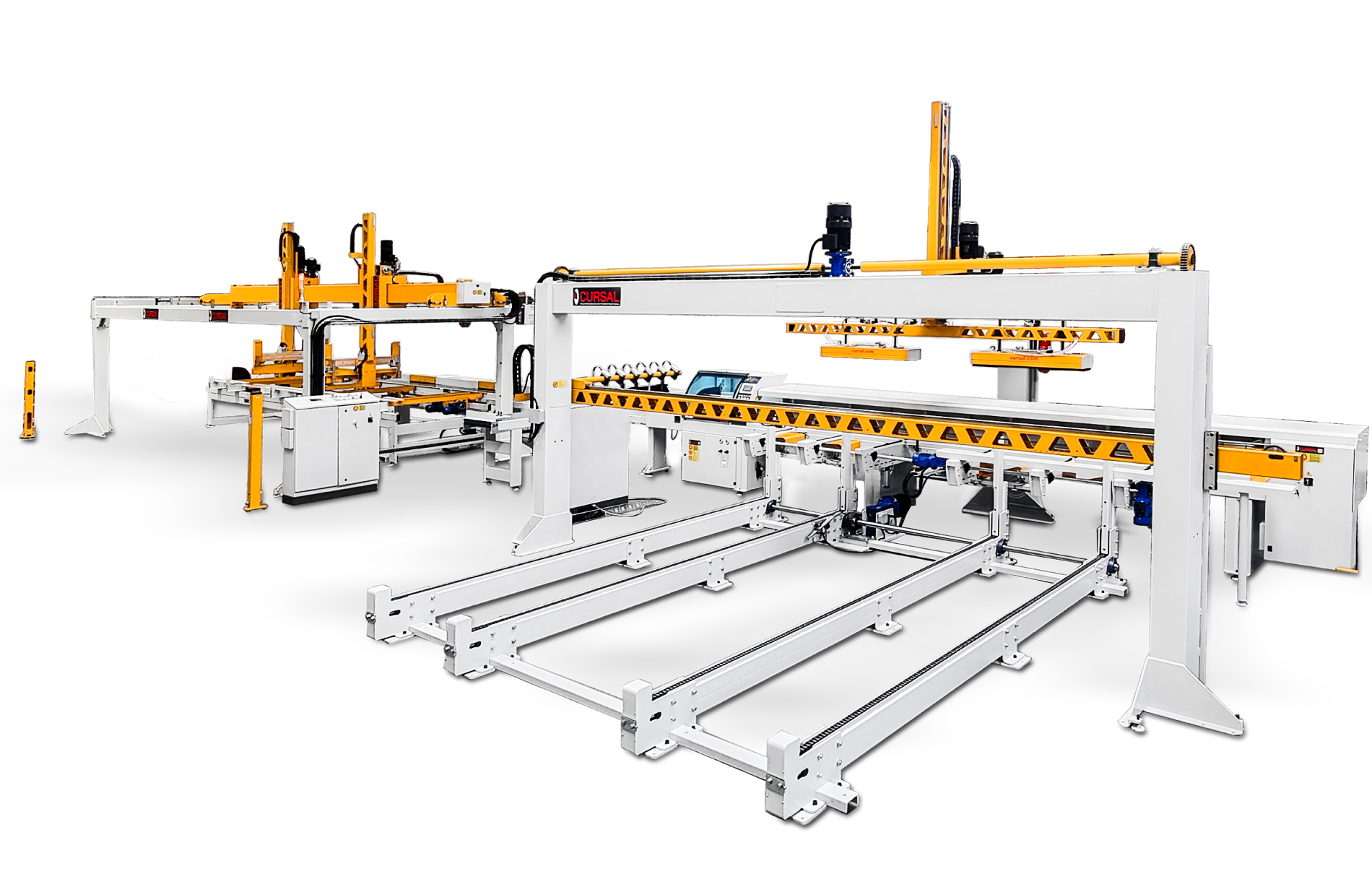

Compact structure, industrial core The TRSI Ø500 stands out with its modular monoblock frame—a solution pioneered by Cursal and since imitated by many—providing maximum stability and resistance to deformation.

This ensures long-term durability, ease of installation, and seamless integration into automated production lines. Its compact footprint allows for space optimization, delivering more technology in less space.

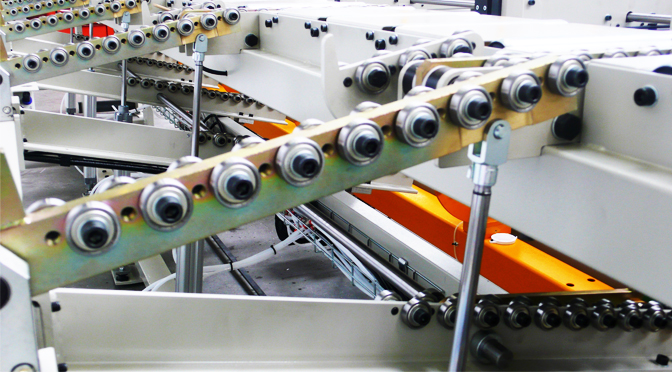

Pusher assembly: the technological core Equipped with Brushless motors and ball-recirculating linear guides, the pusher achieves speeds up to 250 m/min while maintaining millimetric precision.

The motion system is engineered for smooth, controlled operation, optimized for high-volume production cycles without sacrificing handling delicacy.

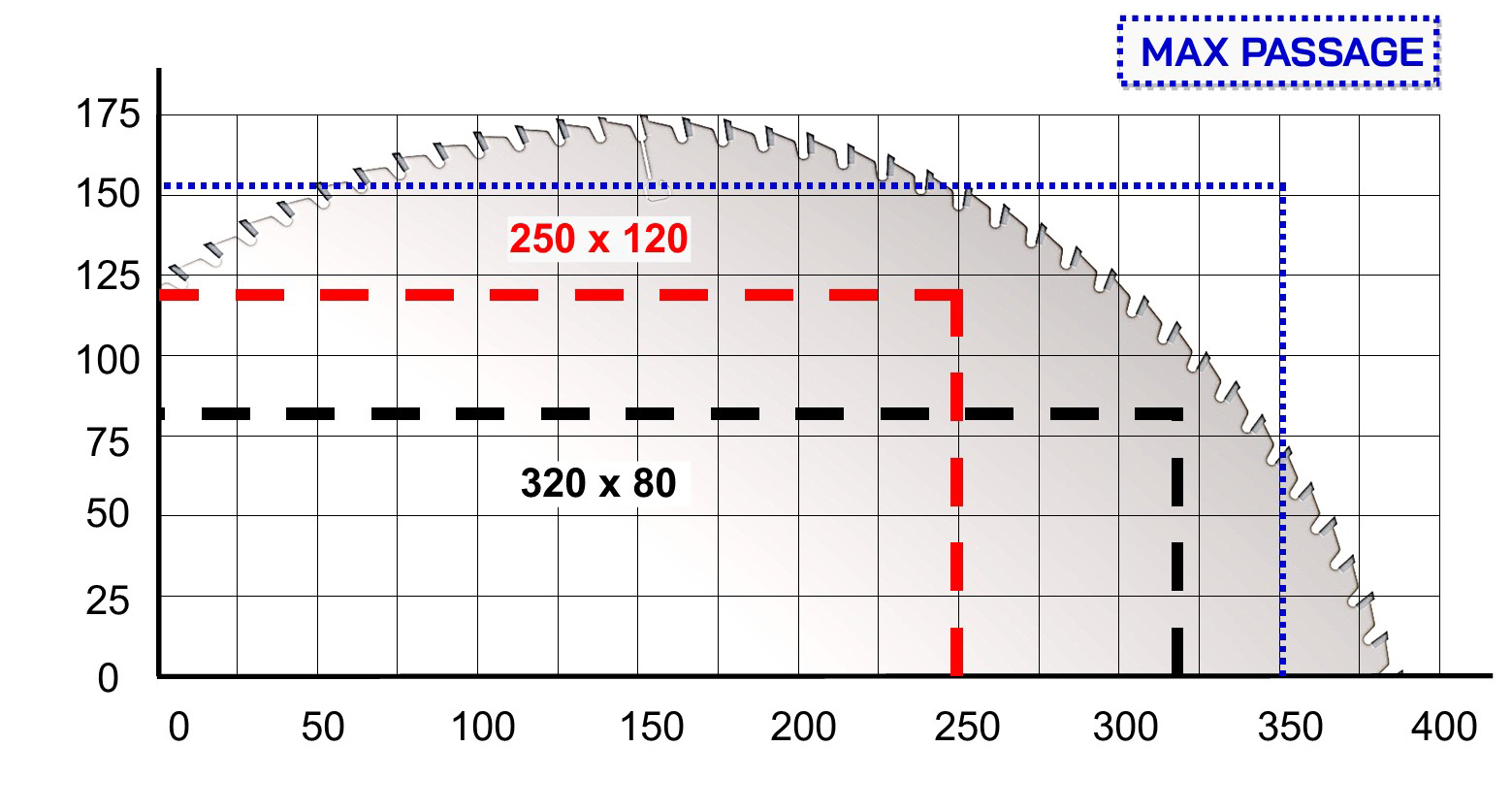

Cutting precision and finish The Ø500 mm blade provides a cutting height of up to 125 mm, making the TRSI Ø500 suitable for single boards, packs, and semi-finished materials, even those that are pre-treated.

The cutting quality remains consistent thanks to durable, high-performance components.

One machine, endless possibilities With its versatile mechanical and software configurations, the TRSI Ø500 is ideal for programmed cutting and defect-optimized cutting, making it perfectly suited for sectors such as packaging, windows and doors, construction, and custom furniture manufacturing.

Details that make the difference Features include a pneumatically lifting pusher, blade pressor on linear-guide, aligners with integrated blower and oil-bath friction rubber wheels ensuring constant thrust.

The machine can be equipped with customizable accessories, as well as automated loading, code marking, and intelligent unloading systems.

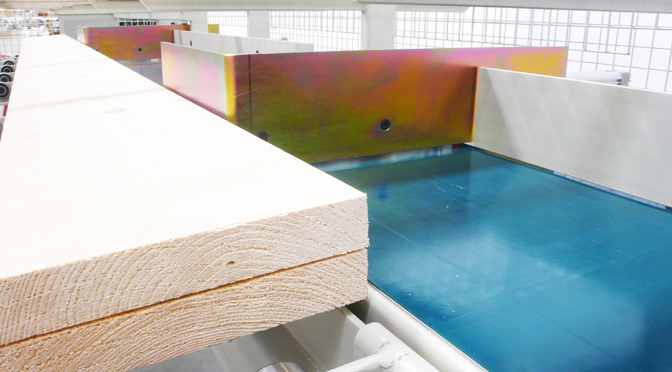

TRSI 500: Modularity, Automation, and Flexibility for the Packaging Sector

Cursal is the benchmark in the packaging sector, which accounts for over 65% of our customer base.

We offer modular and scalable solutions, guiding clients through a path of progressive automation, from the basic configuration to a fully automated system.

The system starts with a ready-to-use standard configuration, ensuring immediate continuity and productivity right from installation:

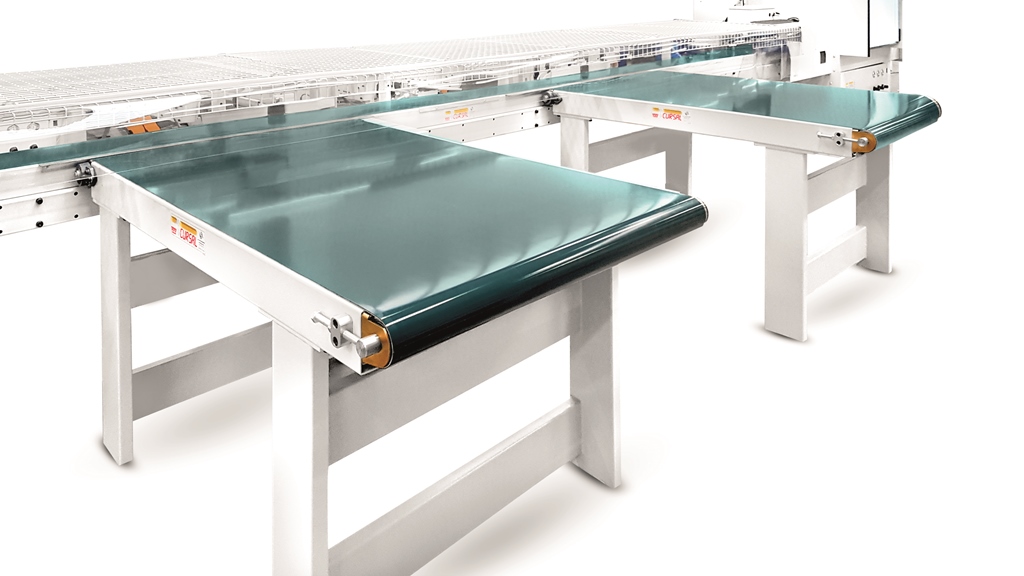

CALS infeed chains to create an orderly buffer

Outfeed ejectors for packets of semi-finished products

Collection via idle roller conveyors for safe and smooth material handling

The configuration can be expanded with automatic loading and unloading systems, addressing the growing demand for labor input and high-throughput productivity.

Sequential Cutting, Maximum Flexibility

Our TRSI series crosscut saws are ideal for fast, accurate sequential cutting.

The TRSI 500 is designed for small to medium workloads, while the TRSI 600 and 700 models are engineered for heavy-duty, high-volume operations.

For angled cuts, we offer the TRGSI model with diagonal cutting capability.

The next step in the range is the TRSI AP, featuring an integrated pneumatic pusher, infeed chains, and speeds of up to 200 m/min.

This version handles packets up to 100 kg with ±0.25 mm accuracy.

Flexibility for Every Packaging Requirement

Our systems adapt to a wide range of production needs—from cutting short, lightweight boards to heavy-duty solid timber.

We ensure cycle optimization in any operational context.

Our lines are installed not only across Italy but on every continent, testifying to an international vision founded on reliability, innovation, and a robust after-sales service.

Optimization in Wooden Window and Door Production

In the wooden window and door manufacturing sector, the TRSI has proven to deliver the best performance in terms of economic return for customers.

Thanks to its high-speed operation—capable of producing in just 8 hours the semi-finished components needed for 400 windows—and its efficient optimization system, developed by Cursal since 1983, the machine allows for ROI within a few months, even when used for only 2 hours a day and without reliance on incentives or subsidies.

In today’s wood joinery production, optimizing workflow, minimizing waste, and ensuring precision are essential.

Every error can compromise the quality of the finished product. TRSI E/OL optimizing crosscut saws are the ideal solution for this context.

The system configuration is specifically engineered for the window and door sector, with millimeter-calibrated uprights and crosspieces. Perfectly suited for cutting solid wood, laminated timber, and finger-jointed material with an accuracy of ±0.25 mm and speeds of up to 200 m/min, thanks to the pusher with Brushless servomotor.

TRSI Model Range

For this sector, the TRSI is available in two variants:

TRSI OL for length optimization and TRSI E for defect elimination.

It is suitable for both artisanal production (independent “stand-alone” machine) and high-capacity industrial cycles.

The system optimizes timber yield, automatically managing lengths, quantities, priorities, and material value, all while respecting the sequential order required by the processing centers, ensuring maximum results.

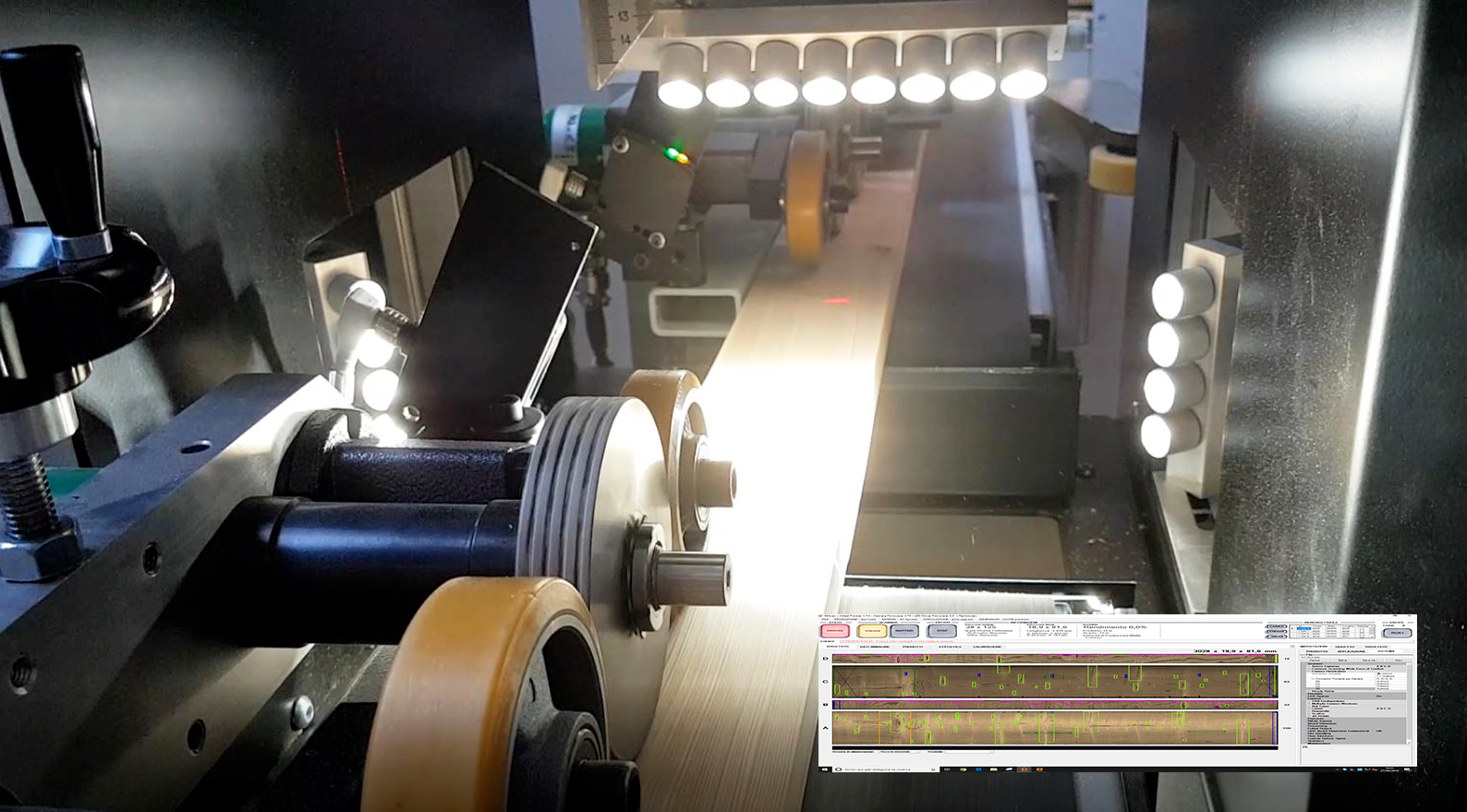

TRSI – INTELLIGENT DRILLING SYSTEM

From design to perfect hole, without interruptions:

The Cursal integrated system optimizes every board with speed, CNC control, and total flexibility

REAL-TIME AUTOMATIC OPTIMIZATION

The integrated drilling system within the TRSI optimizes every stage of production.

After automatically scanning the board, the software calculates the combined cutting and drilling plan, transmitting it in real-time to the crosscut saw. This ensures synchronized production, error-free operations, reduces cycle times, and maintains consistent quality, even with mixed batches or variable materials.

Modular Configurations for Every Need

The drilling module is flexible, with options of 1, 5, or 18 spindles, depending on production needs.

The standard configuration features 5 independent spindles, positioned before the saw blade.

Each spindle, in addition to the CNC stroke, has a 70 mm pneumatic stroke, with drill bits up to Ø25 mm.

The Brushless motor and carriage with recirculation ball bearing ensure ensure precision and reliability. The system accommodates various lengths, diameters, and drill depths with maximum accuracy.

CNC-controlled aligners

The alignment system, consisting of 2 independent axes with pneumatic strokes of up to 300 mm and 125 mm, is mounted on carriages wheels and recirculation ball bearings.

Controlled by PLC, it ensures piece stability during processing, preventing any micro-movements that could compromise precision.

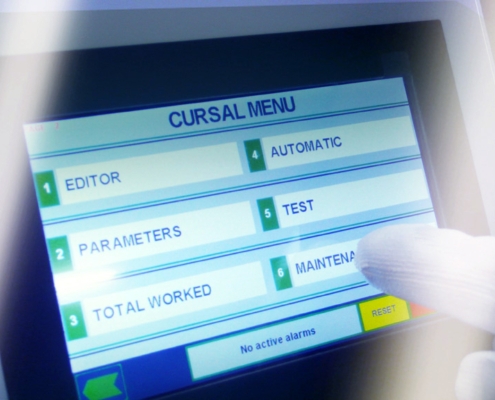

Complete Management via Industrial PC

The management core is an industrial PC running Windows 11, equipped with an LCD monitor, wireless keyboard, and mouse. Communication between the CNC and PC is guaranteed via Ethernet/USB ports.

The software manages CNC, printers, and labelers, utilizing .txt/.csv files for integration with client management systems, offering remote support. Cursal also provides customizable solutions for clients without proprietary software, using the SGPC-1 package.

Precision and Operational Continuity

The integration of hardware and software enables simple and customizable programming for lengths and drilling, eliminating manual steps.

The result is an automated, compact, and high-performance line that meets the modern needs of the wood industry, ensuring efficiency, quality, and continuous production.