FIREWOOD – MULTIRIPPED TRIMMINGS SAW TRV 1200L BLADE Ø 550

AUTOMATIC CUTTING OF WASTE WOOD RECOVERING FIREWOOD, CONTINUOUS PRODUCTIVITY

At the heart of modern sawmills, where every cubic meter matters, CURSAL’s TRV 1200L and 1600L crosscut saws offer a concrete, reliable, and high-performance solution for the industrial recovery of solid wood waste.

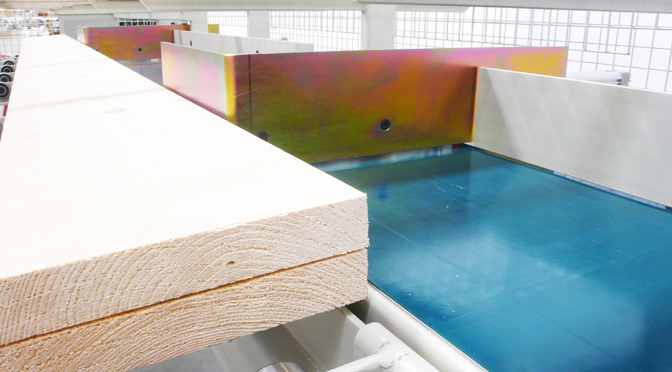

Designed for the recovery of side wastes and heterogeneous wastes, the TRVL models transform what is typically considered bulky, marginal material into a highly demanded, ready-to-use resource.

For CURSAL, waste is not discard: it is valuable raw material.

ROBUSTNESS AND AUTOMATION, WITHOUT COMPROMISE

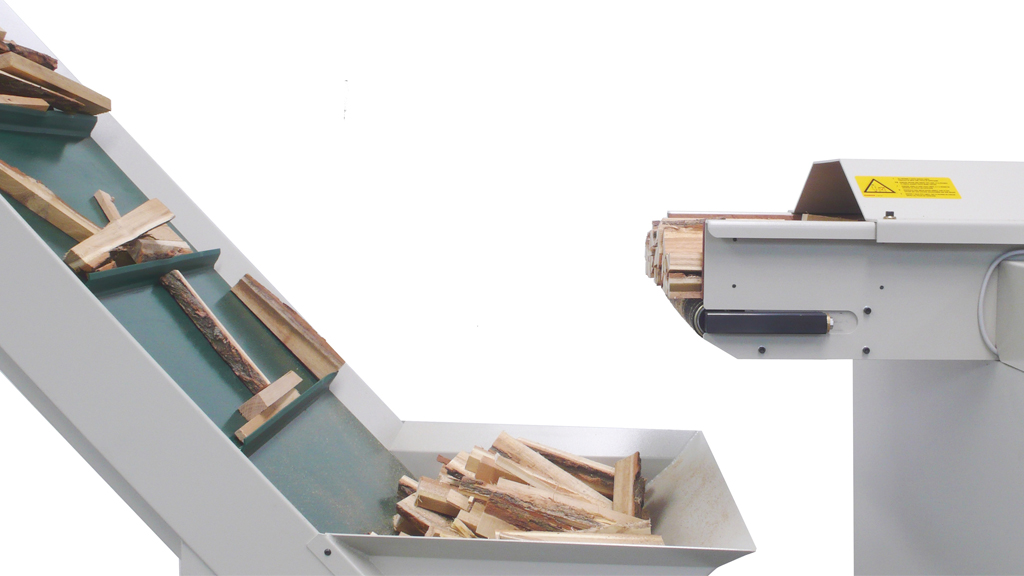

TRVL saws operate smoothly and continuously, even with overlapped, irregular, or loosely stacked pieces.

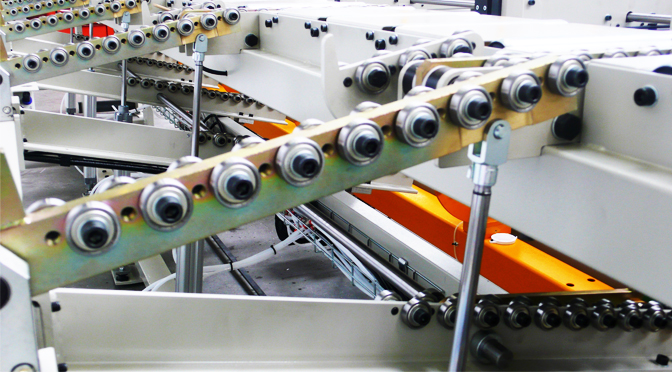

The low-wear conveyor feed system, combined with a sectional unit of independent pneumatic cylinders, ensures constant pressure and secure blocking on any shape and thickness during cutting.

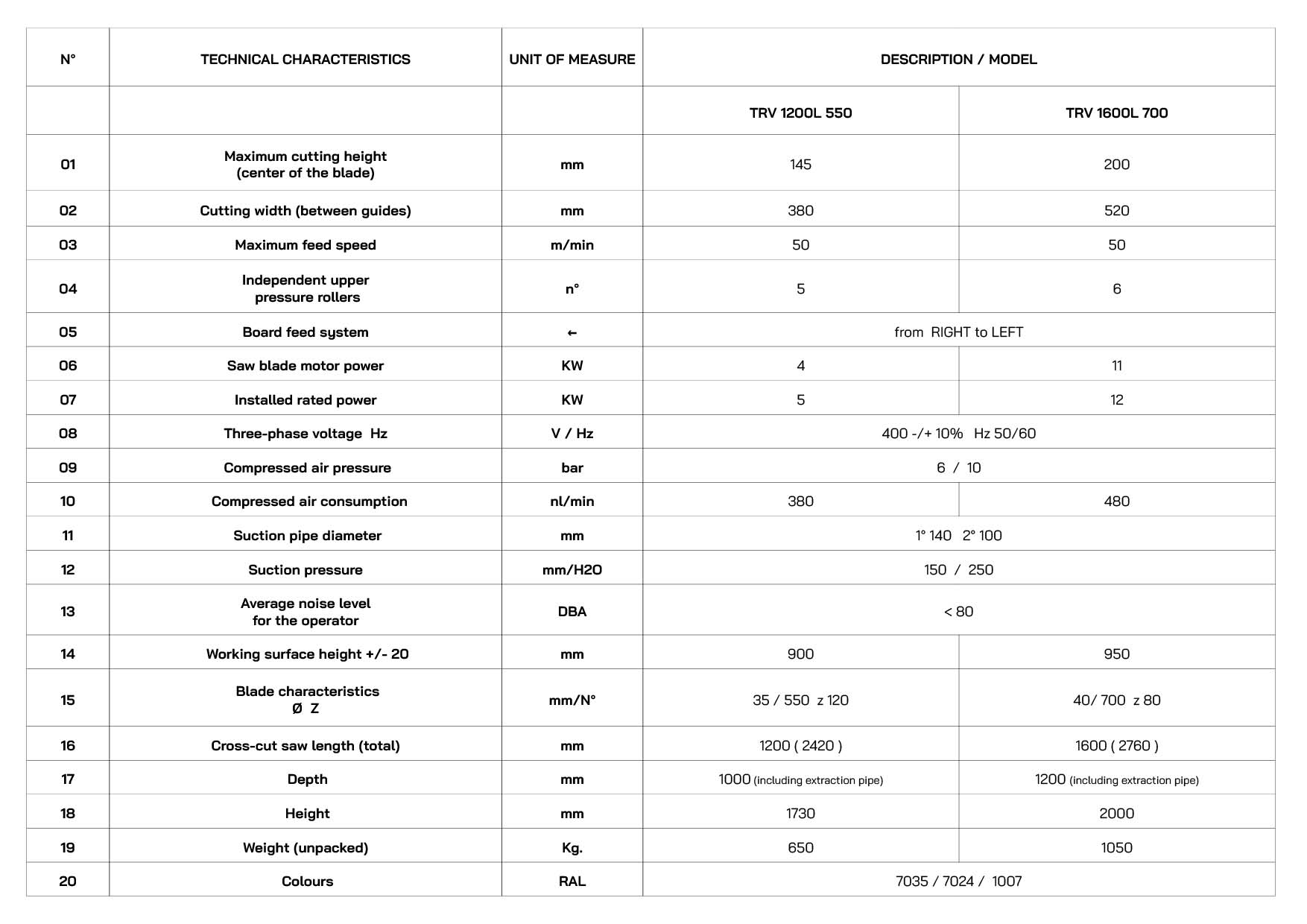

Available in two configurations:

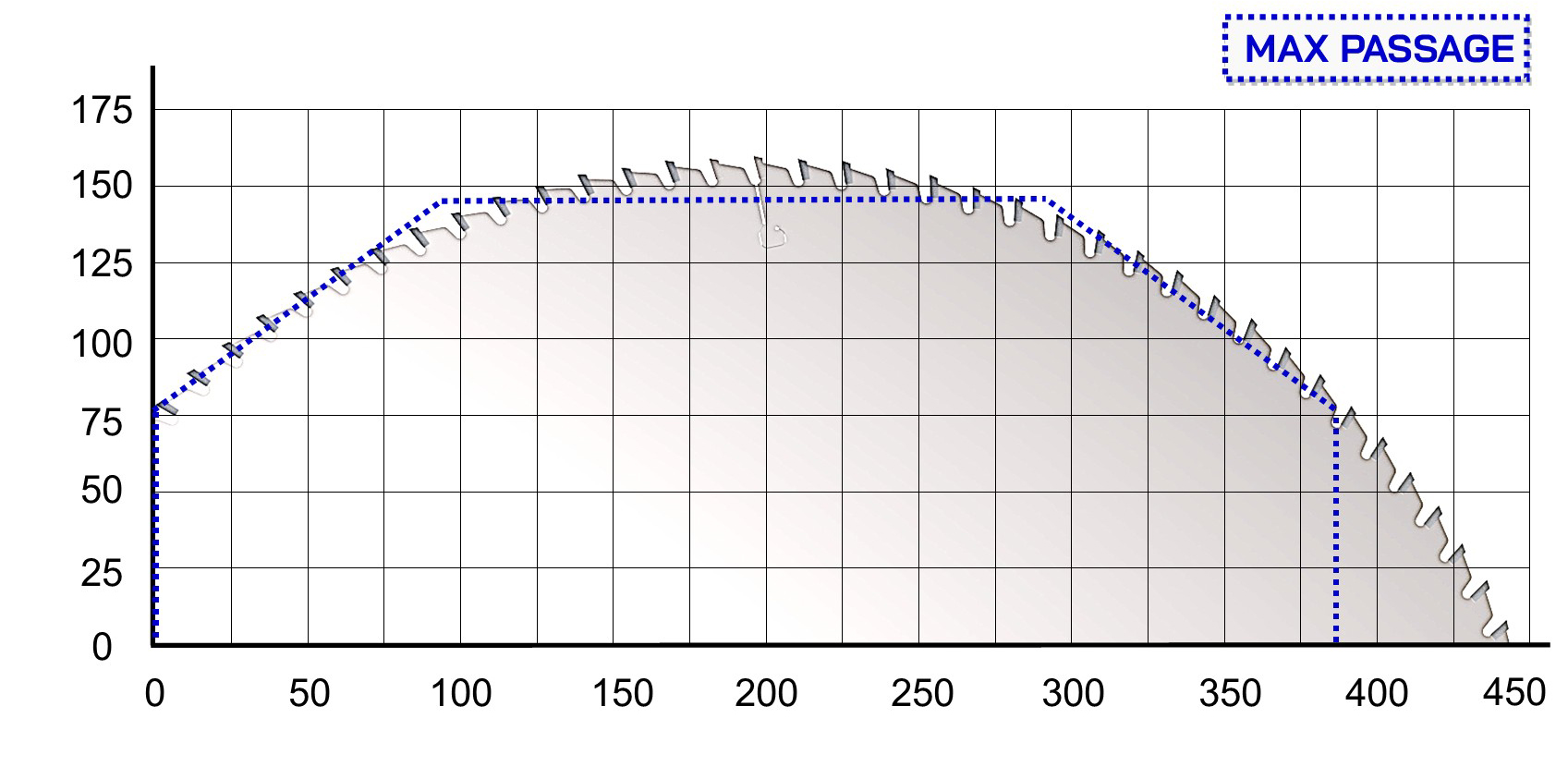

TRV 1200L (Ø550 mm) – Compact, tireless, ideal for limited spaces yet nonstop productivity

TRV 1600L (Ø700 mm) – The heavy-duty answer for large sawmills: reinforced frame, 6 independent sections, and superior cutting capacity

THE CURSAL ADVANTAGE

Integrating a TRVL unit into your plant results in:

– drastic reduction of waste and disposal costs

– immediate value recovery of wastes: their value triples in less than a minute

– elimination of manual recovery, a frequent source of operator injuries

– elimination of disorganized wastes storage

– a fully automated cycle. Easy to integrate via PLC control, the TRVL features a monolithic steel frame, premium industrial components, and simplified maintenance — making it a durable and long-lasting machine, even under the most demanding conditions.

THE CHOICE FOR THOSE WHO AIM HIGH

Today the TRV 1200L–1600L are installed in major European sawmills, with multiple units per facility.

Because anyone who work wood daily know that a solid, automated machine is the line between waste and value.

TRV 1200L–1600L: not just crosscut saws, but performance multipliers

TRV 1200L – COMPACT IN SIZE, GIANT IN RESULTS

The TRV 1200L is designed to add value to what is often discarded.

Developed to optimize solid wood by-products, it is the ideal crosscut saw for transforming trimmings, short logs, and waste into firewood or reusable materials—continuously and without compromise.

Engineered to resist, built to perform

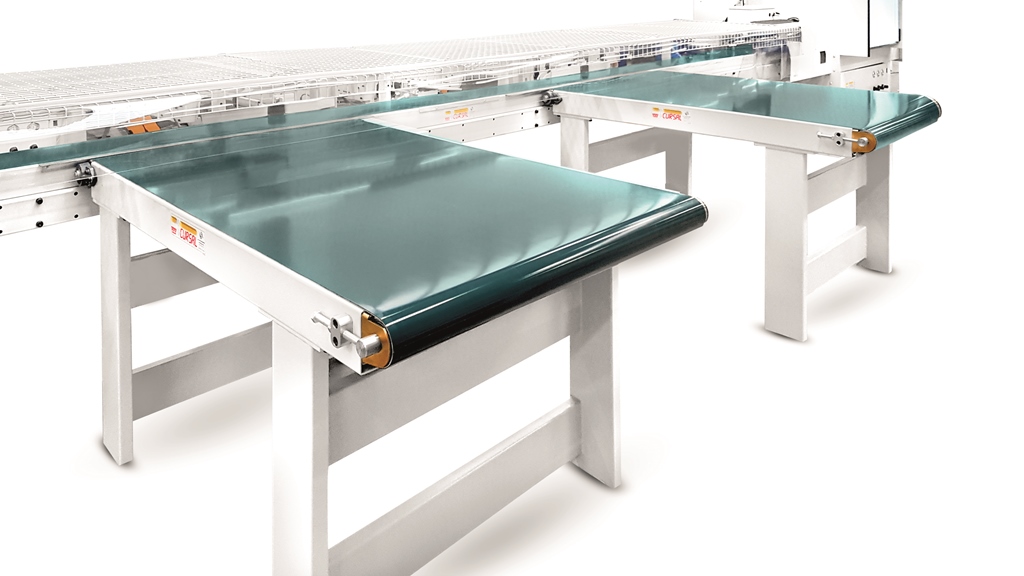

Solid and compact, it operates continuously even over multiple shifts, integrating seamlessly into environments with high volumes of waste from multi-blade saws, crosscut saws, or edging lines.

Its high-strength, electro-welded steel frame eliminates vibrations and deformation, ensuring long-term reliability under heavy loads.

The cutting unit features a Ø550 mm blade powered by a strong, precise motor capable of handling irregular materials with ease.

The loading area, configurable with a low-wear belt and cushioned base or with roller conveyor, is designed to absorb impacts from sharp-edged or irregularly shaped pieces without compromising the structure.

Smart sectional blocking system: five independent pneumatic cylinders with shock absorbers apply selective pressure on the workpieces, ensuring safe blocking during cutting, even with overlapped elements or varying thicknesses.

A technical detail that makes the difference in automated material handling.

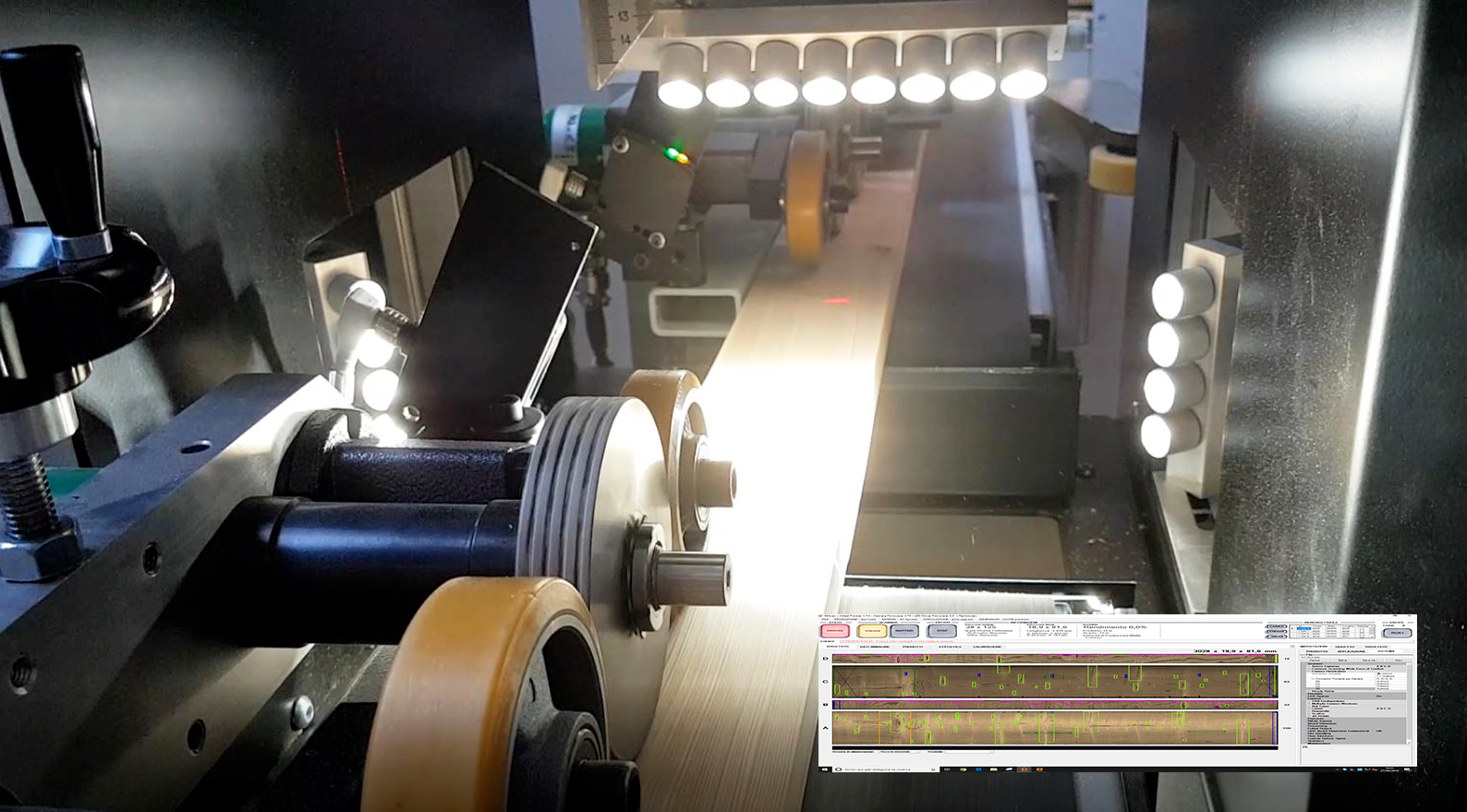

At the heart of the system is an advanced, fully protected industrial PLC.

It manages automatic and timed cuts, regulates feed speed, and allows the operator to easily monitor and program the cutting length.

The machine adapts to material characteristics without sacrificing productivity or precision.

Choosing the TRV 1200L means relying on a tireless machine capable of recovering value where others see only waste.

Eliminate your waste stockpile: you’ll recover both space and value in no time.