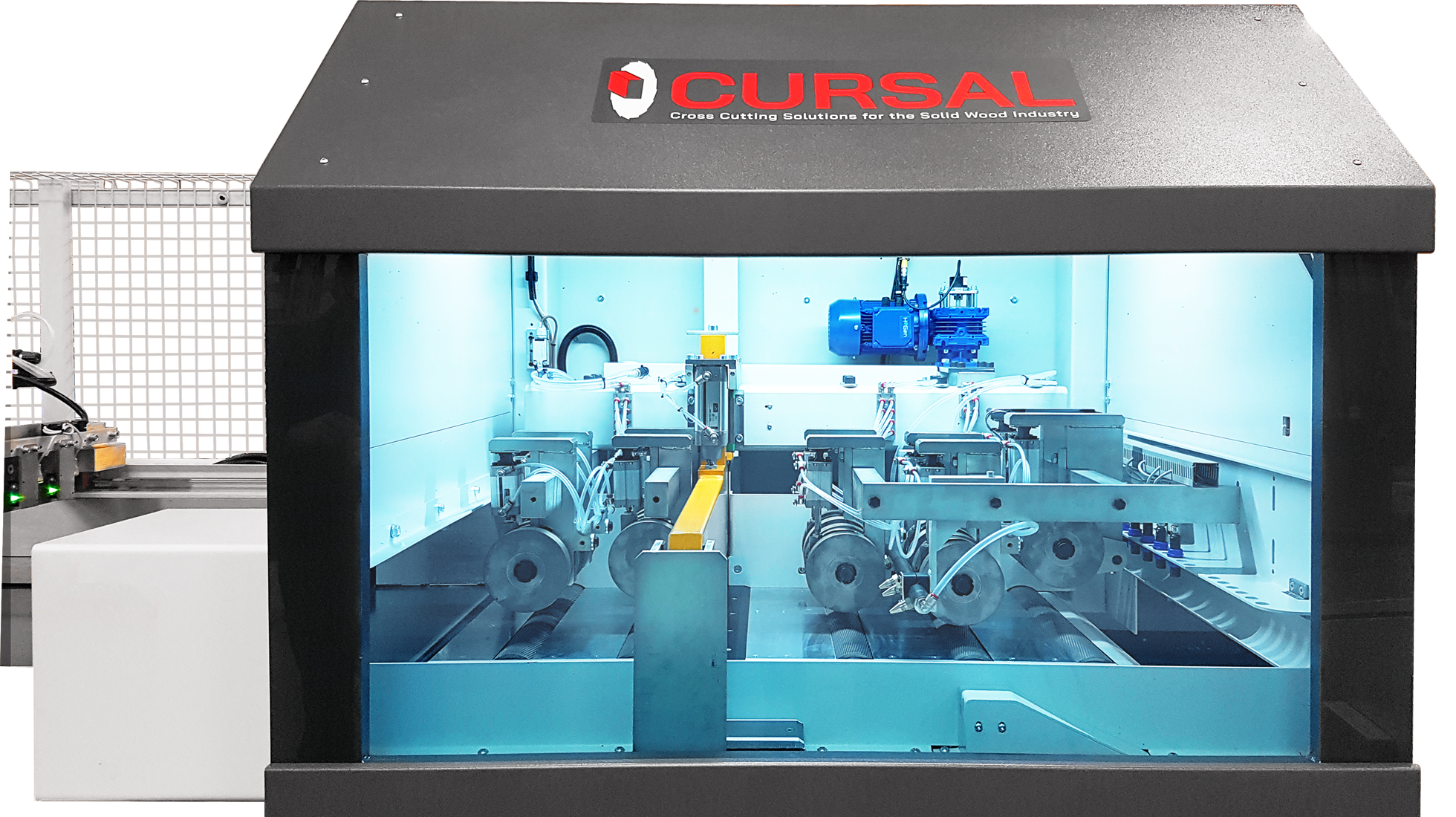

ROLLERS FEEDING OPTIMIZING CROSSCUT SAW – TROE BLADE Ø 550

ROLLER FEED: THE STRONG LINK IN THE SAWMILL, IN-LINE WITH LOG SAWS AND MULTIBLADE SYSTEMS

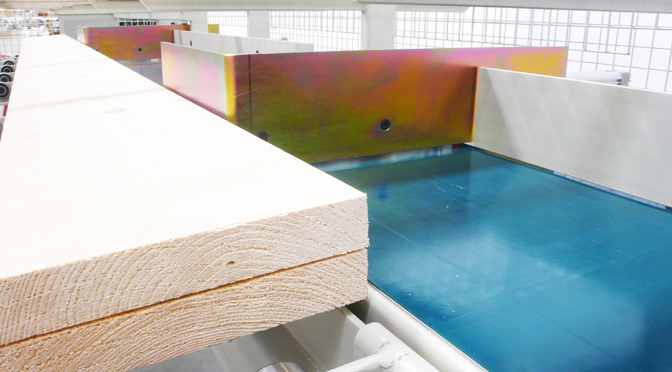

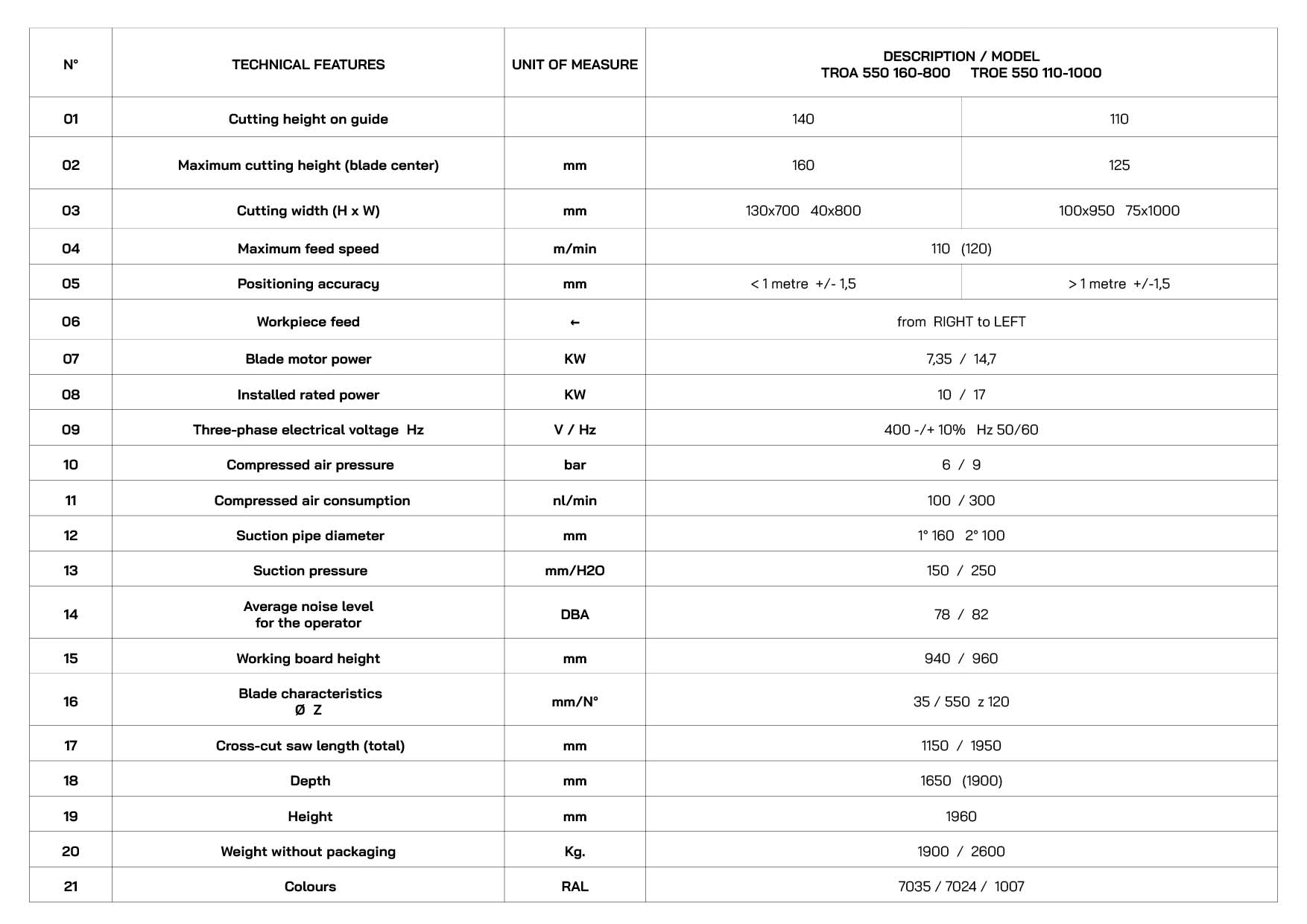

TROA and TROE series are advanced solutions for automatic and optimized crosscutting, specifically designed for the sawmill industry.

With nearly 50 years of experience, Cursal has developed this series to compete in speed with the fastest log saws, including bidirectional ones—reducing processing cycles, optimizing material handling, and minimizing waste.

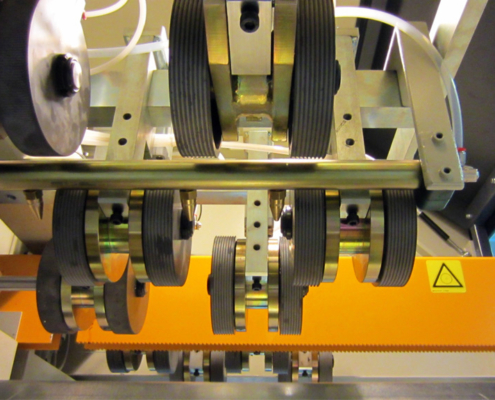

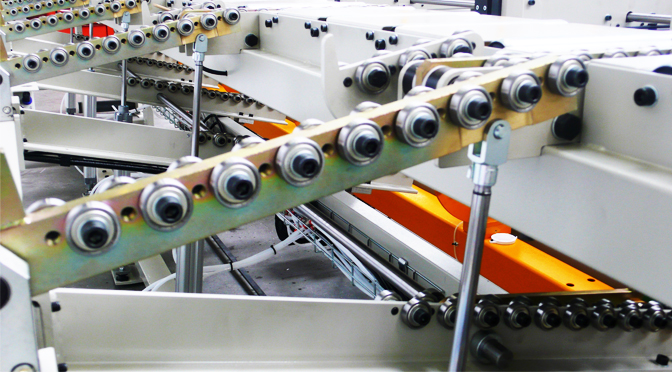

These machines are distinguished by the pulling system with rollers and nitrided wheels with independent pressure.

Engineered to withstand the toughest conditions—such as processing of hard, wet, or frozen wood—and also suitable for dried, warped, or cracked boards along their entire length, the TROA and TROE are built on a rugged frame designed to handle such challenges while ensuring long-term reliability.

The roller and toothed wheel feed system is the key strength of these machines.

Unlike push-feed positioning systems, CNC-controlled roller traction guarantees higher speeds, even with irregular materials, while maintaining continuous operation.

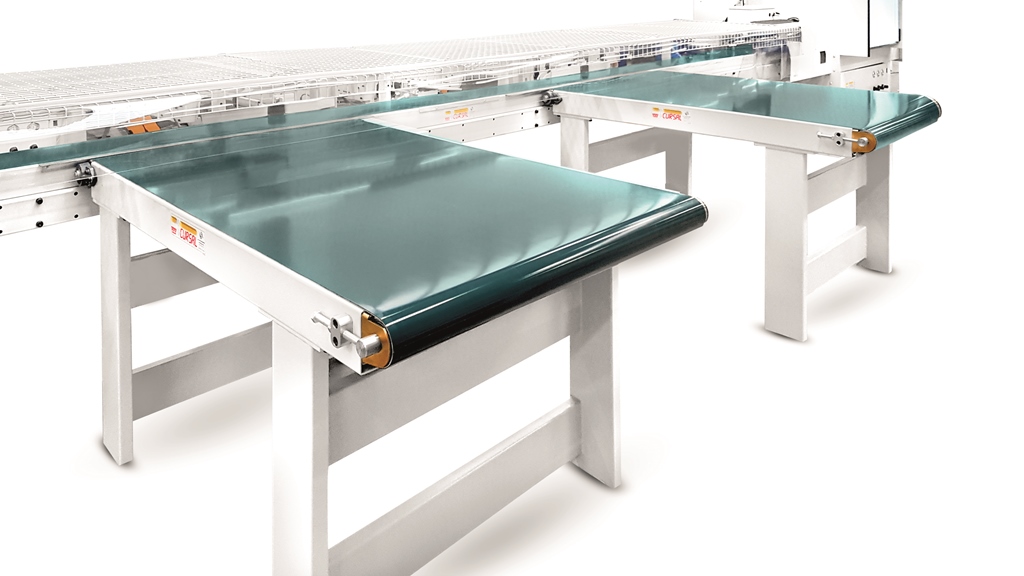

The machines are equipped with a heavy, welded and CNC-machined carpentry structure.

The wear parts are easily inspected, ensuring simple and long-lasting maintenance.

TROA and TROE series offer high-speed feed motion, powered by Brushless motors.

Feed rates reach up to 110–120 m/min, and blade motors from 15 to 20 HP are equipped with self-braking systems, delivering powerful, precise cuts. They also include an automatic tension release cycle for boards with internal stress—capable of stopping even the most powerful systems—offering a unique Cursal solution.

To complete the production line, many customers integrate TRVL cross-cut saws, the ideal choice for converting bulky waste pieces from multiblade machines into ready-to-use firewood for the end user.

The TROA and TROE are designed to offer consistent performance, safety, and durability—establishing themselves as a benchmark for modern sawmills demanding robust, high-performance cutting systems.

TROE AUTOMATIC CROSSCUTTING + ADVANCED DEFECT OPTIMIZATION

AUTOMATIC CROSSCUTTING + ADVANCED DEFECT OPTIMIZATION

TROE is an advanced crosscut saw designed to optimize sawmill operations, offering innovative solutions for cutting and defect management in wood.

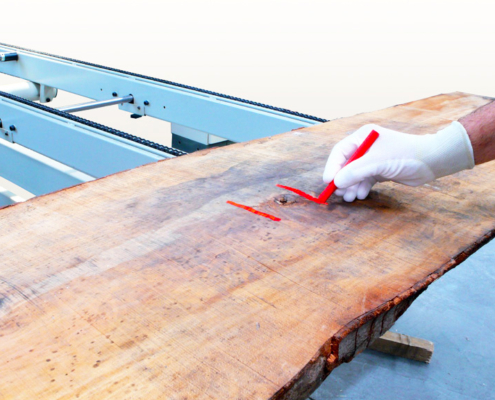

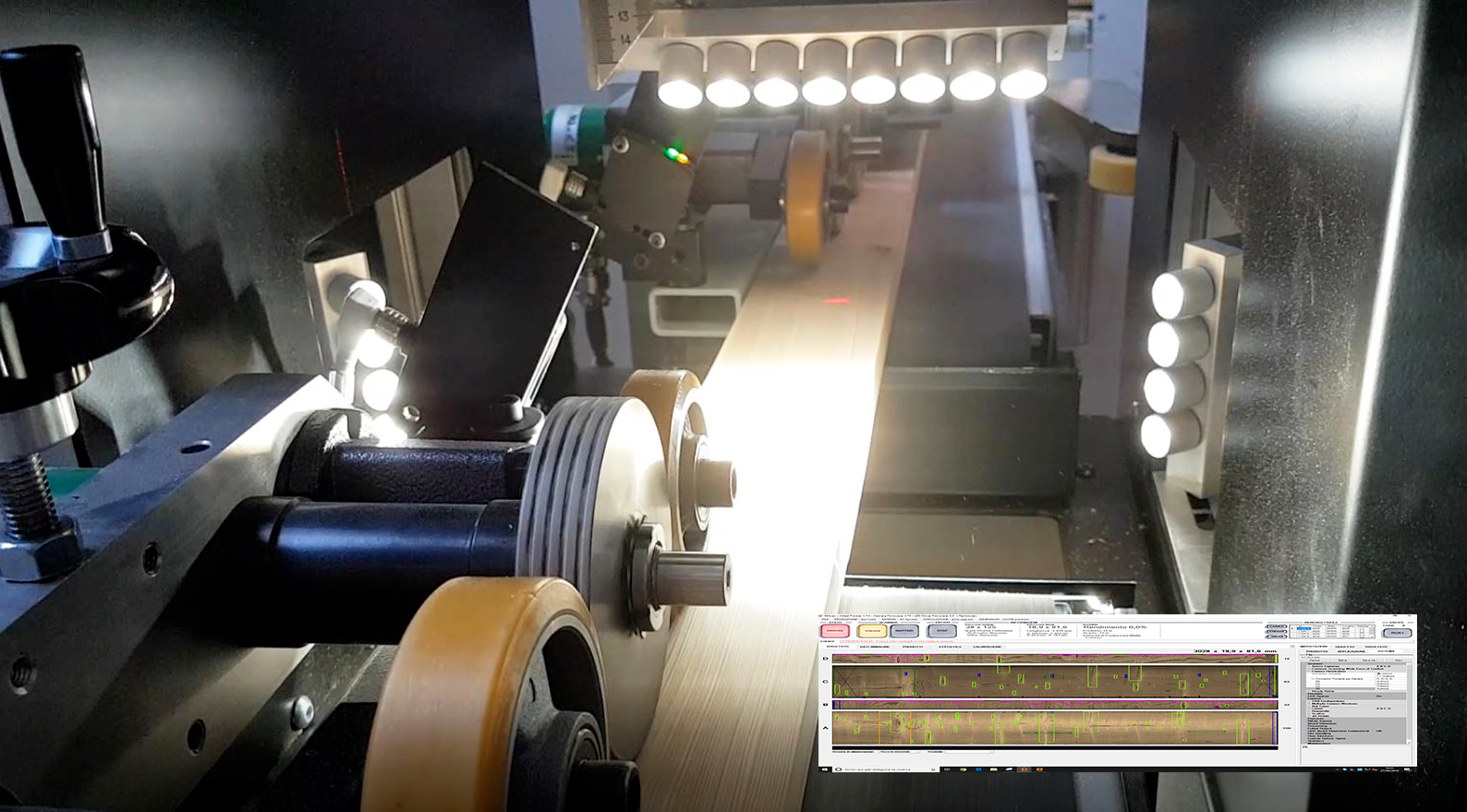

Thanks to its real-time board scanning capability, TROE automatically identifies marked defects and calculates the most efficient cut, ensuring precision and maximum yield.

Equipped with high-resolution cameras, TROE performs optical reading of luminescent markings (fluorescent chalk marking) to detect imperfections, knots, cracks, and other areas to be discarded.

The cutting logic is fully customizable: the operator can prioritize wood value, usable length, production quantity, or minimize waste.

Ideal for processing high-quality woods, TROE drastically reduces waste and ensures full automation of the crosscutting process, maximizing efficiency and cut quality.

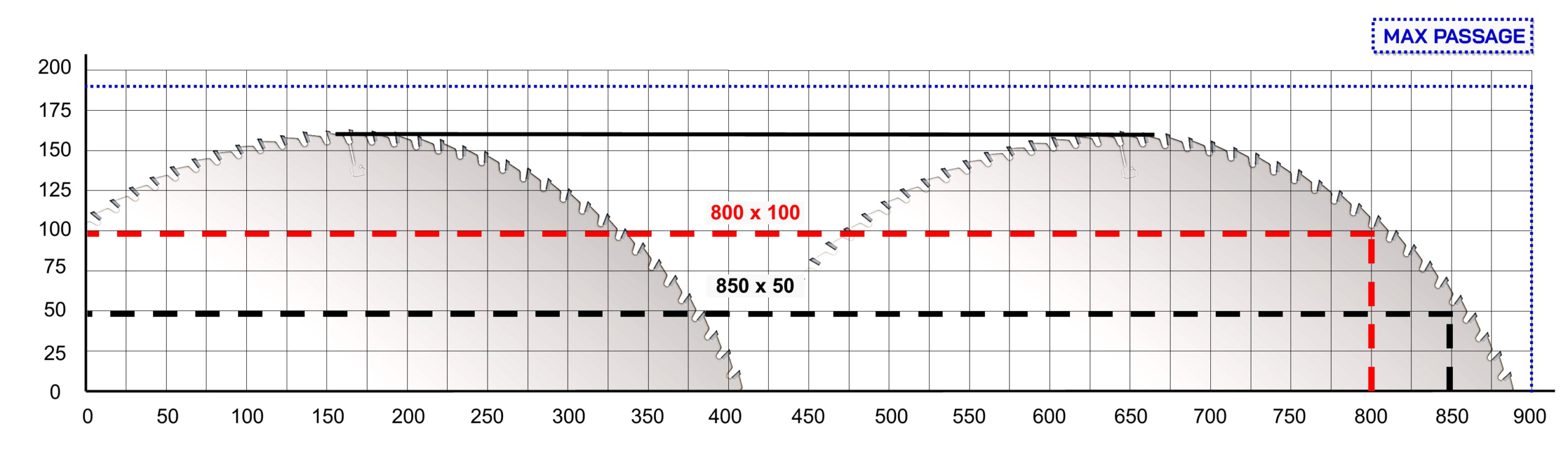

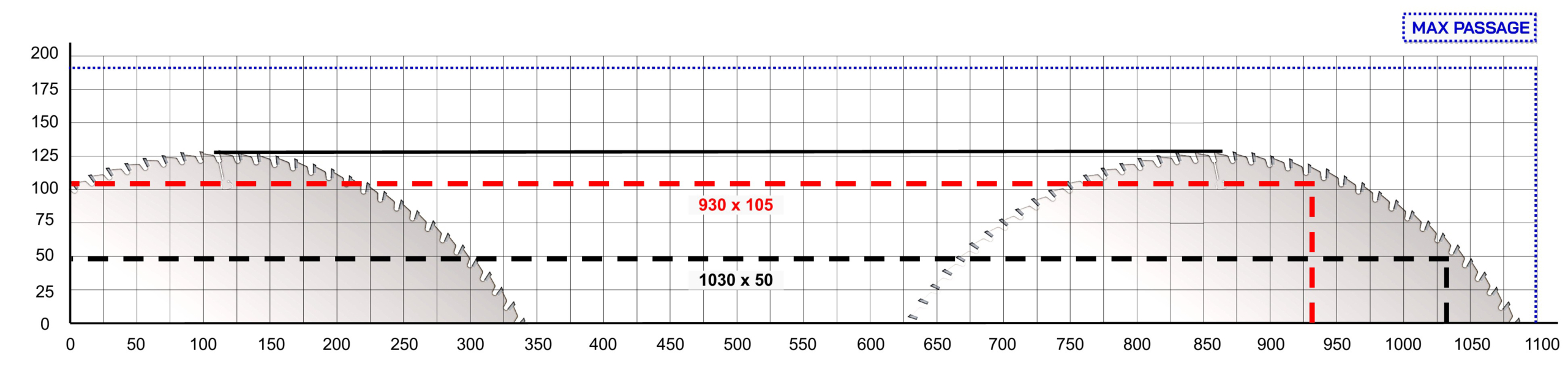

TROE 550-110-1000 HS – Advanced Optimization

The TROE HS is ideal for modern, automated production lines integrated with MES systems.

Thanks to advanced technologies, it ensures superior performance and optimal management of the crosscutting process.

MAIN FEATURES:

Optimization Simulator: Real and virtual board for flexible and precise management.

Defect Detection: Analyzes boards up to 6 meters long with high precision.

Automatic Ejection: Smart waste management with options for fragmentation or recovery.

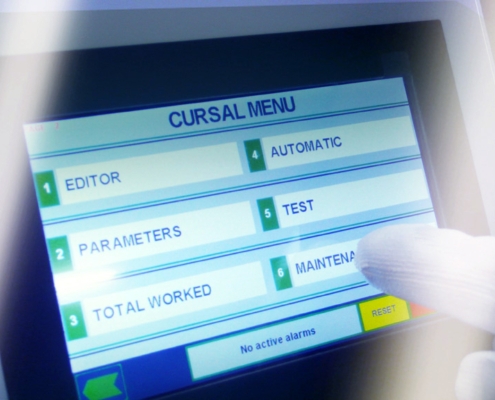

Advanced CNC Touch-Screen:

Stores up to 128 measurement groups, 16 widths, and 8 qualities per order.

Multiple Interfaces: USB, Ethernet, RS232/485 for compatibility with enterprise systems.

KEY ADVANTAGES:

Feed speed of up to 120 m/min.

125 mm vertical blade stroke for quick and precise cuts.

High positioning accuracy: tolerance of ± 0.2% on lengths over 1 meter.

Continuous or alternating optimization with automatic table exchange in case of out-of-tolerance combinations (optional).

RECOMMENDED APPLICATIONS:

Production of high-quality furniture components

Wooden flooring, parquet, and planks

Automated sawmills and processing of high-end woods