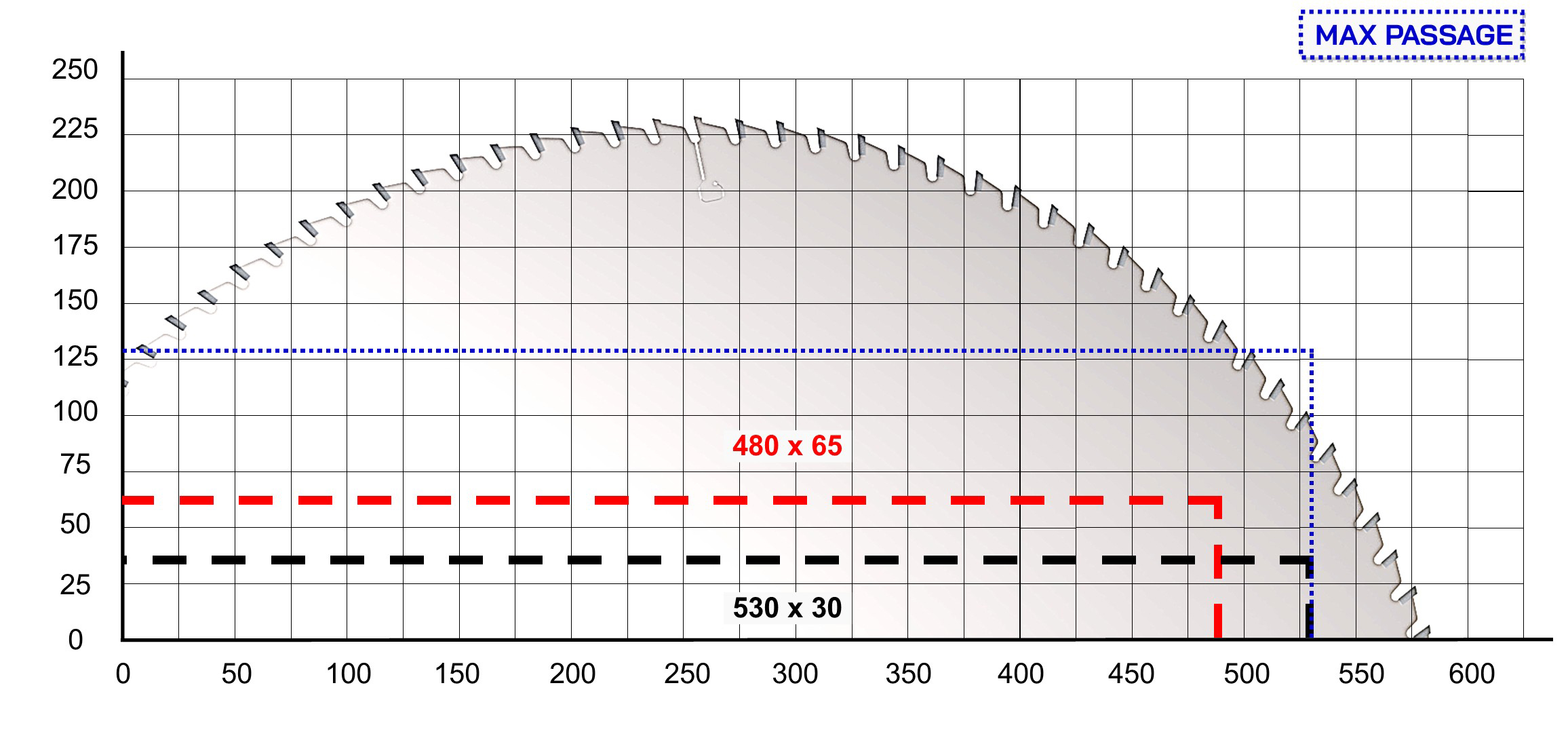

ROLLERS FEEDING OPTIMIZING CROSSCUT SAW – TRV 2000R BLADE Ø 700

THE OPTIMIZER THAT SOLVES SAWMILL CHALLENGES

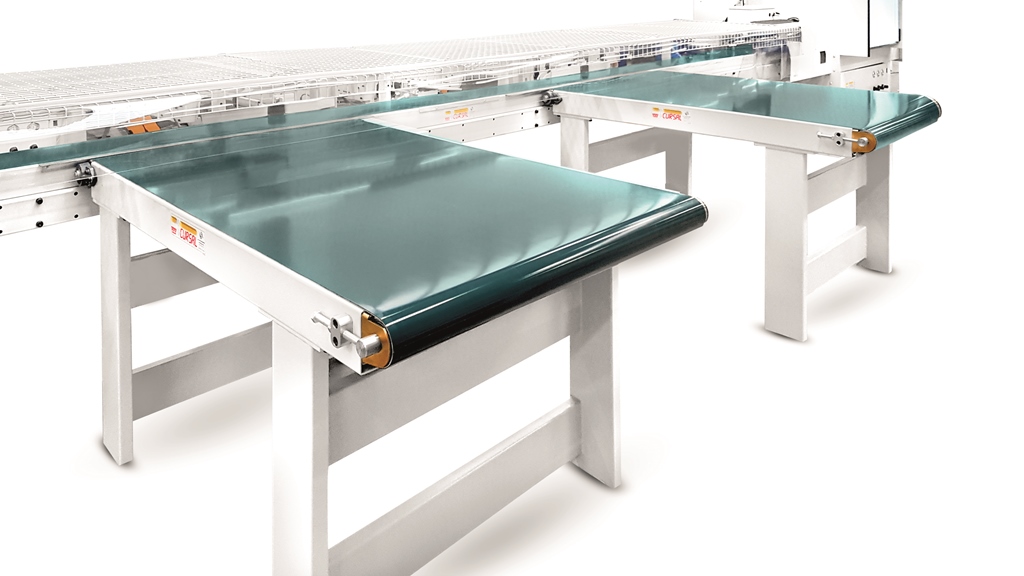

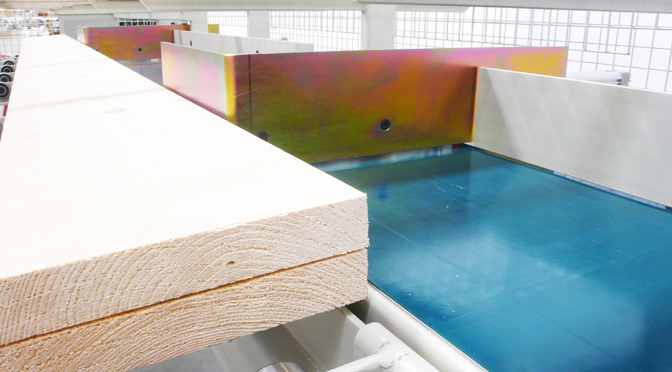

Designed to handle the intense pace of primary processing in sawmills, the TRV 2000 700 represents the pinnacle of Cursal technology: automatic, continuous-cycle optimizers with belt feed for inline side-board recovery from log breakdown, or roller feed for selecting quality in dry, high-grade hardwoods and defected boards.

Engineered to maximize speed, yield, and precision on both rough and edged boards.

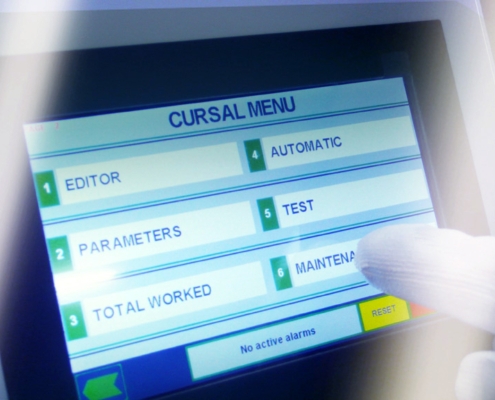

INTEGRATED INTELLIGENCE

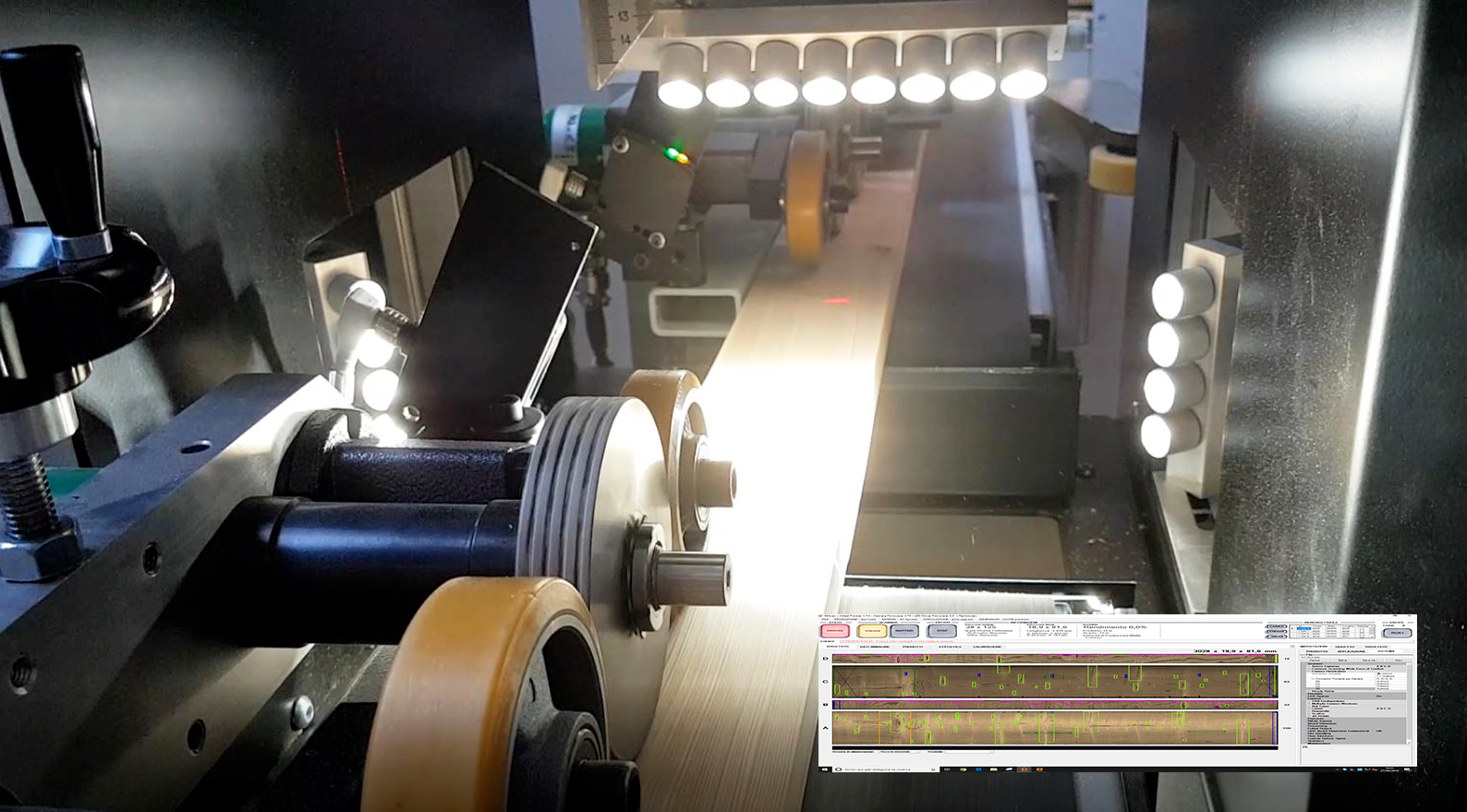

At the core of the system is Cursal’s software, capable of reading, analyzing, and optimizing every board before cutting.

A dedicated camera detects luminescent chalk marks and, using pre-set algorithms, selects the optimal cutting strategy—by value, quantity, or yield.

CONTINUOUS PRODUCTION WITHOUT BOTTLENECKS

TRV 2000 machines work inline without stops or buffer zones, even with irregular or variable loads.

Compatible with both new and existing systems (log breakdown lines, movable gang saws, planers, scanners), they are the operational core of fully automated industrial lines.

ADVANCED FUNCTIONS

The TRV 2000 benefits from software perfected over thousands of installations on premium wood optimizing lines: 128 simultaneous dimension groups, cutting modes by defect, mark, list, or job order, automatic table switching, data export in Excel format, USB, Ethernet, RS 232/485 interfaces, real-time cycle simulation and control, intelligent end-of-batch auto stops, and more.

CURSAL INDUSTRIAL ENGINEERING

Electronic vertical blade movement

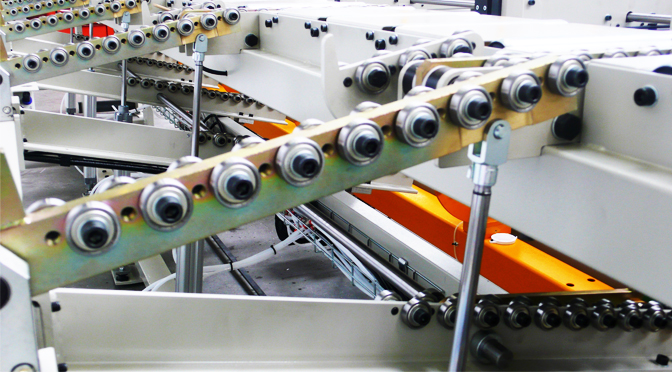

Upper carriage with independent, adjustable wheels

Full safety guards, anti-intrusion sensors, and pressurized control cabinet

Compact modular frame, ideal for customized layouts

Speeds up to 150 m/min, self-limited

THE RESULT?

Less waste, higher yield, reduced time, full traceability.

TRV 2000 is much more than a crosscut saw:

it’s an investment that turns into real, daily operating margin.

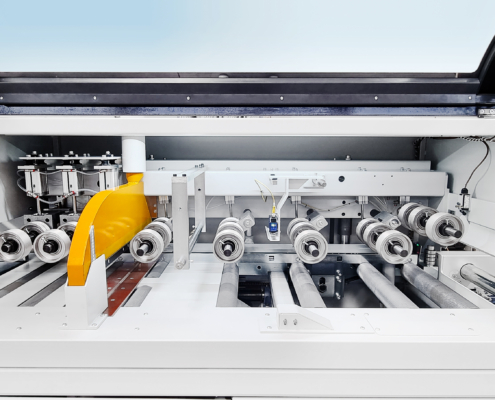

WHERE WOOD RESISTS

TRV 2000R – TOUGH TRACTION

When the wood is challenging — rough, dry, or irregular — the TRV 2000R steps in with an unyielding grip.

Equipped with 8 motorized toothed rollers, it ensures consistent feed even with difficult boards, maintaining stability, accuracy and pace.

MECHANICAL POWER, DIGITAL INTELLIGENCE

Cursal’s software reads and optimizes in real time, detecting marked reference points on the wood and converting them into efficient cutting operations.

Up to 128 simultaneous dimension groups – Cycle simulation, Excel-compatible data saving – Automatic table switching (fixed or alternate) – USB, Ethernet, RS232/485 interfaces for full system integration

TRV 2000EB 700R – THE HIGH SPEED VERSION

For those pushing to the limit:

– Brushless servomotor for fast, controlled cuts

– up to 40 cuts/minute on 500 mm pieces

– 19 kW power – Cutting capacity up to 35,000 mm²

– high performance even in the most demanding cycles

READY FOR ANY INDUSTRIAL LINE

The TRV 2000 700R is built to endure, drive, and optimize.

A perfect blend of mechanical grip and software intelligence, designed to deliver uninterrupted flow, no jams, and measurable results.