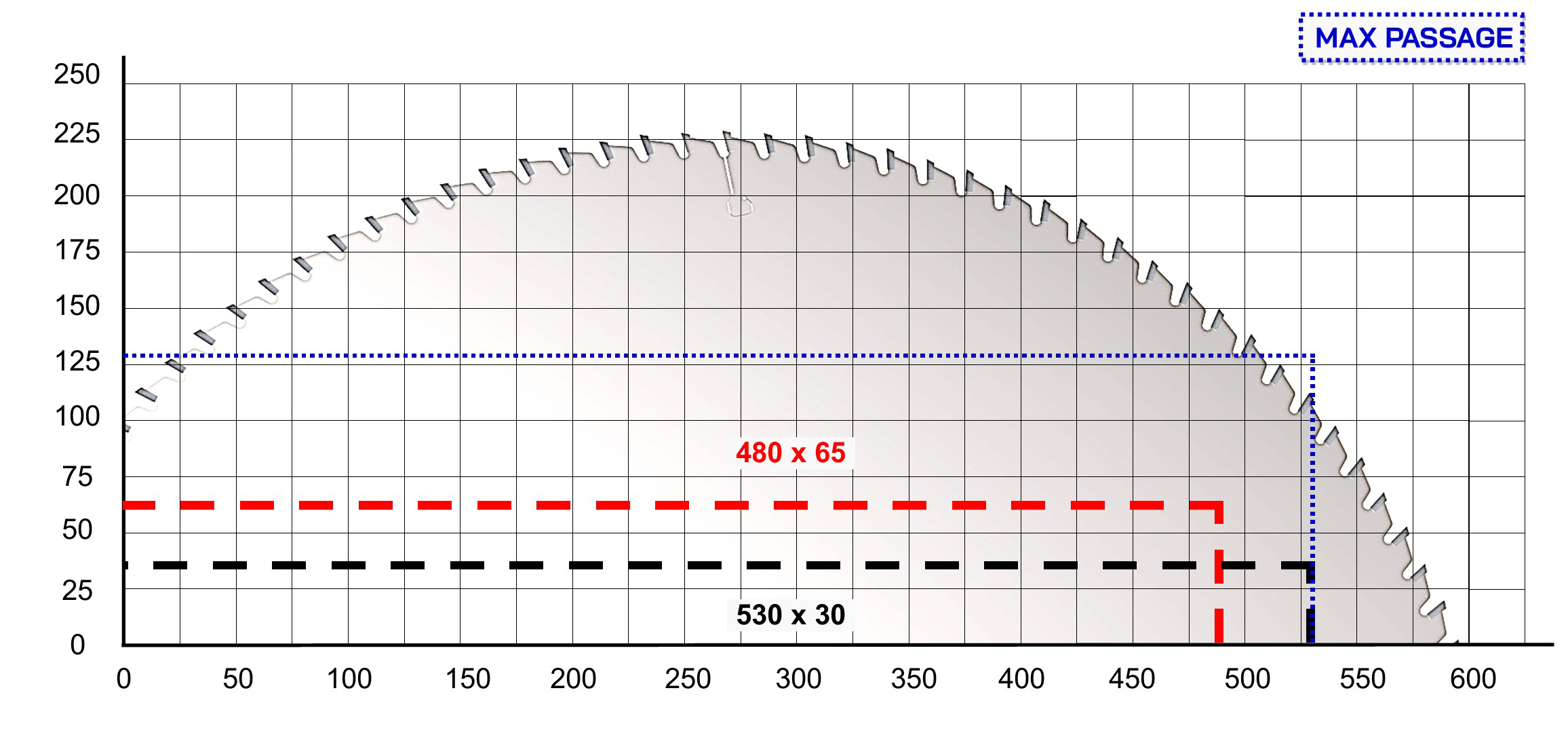

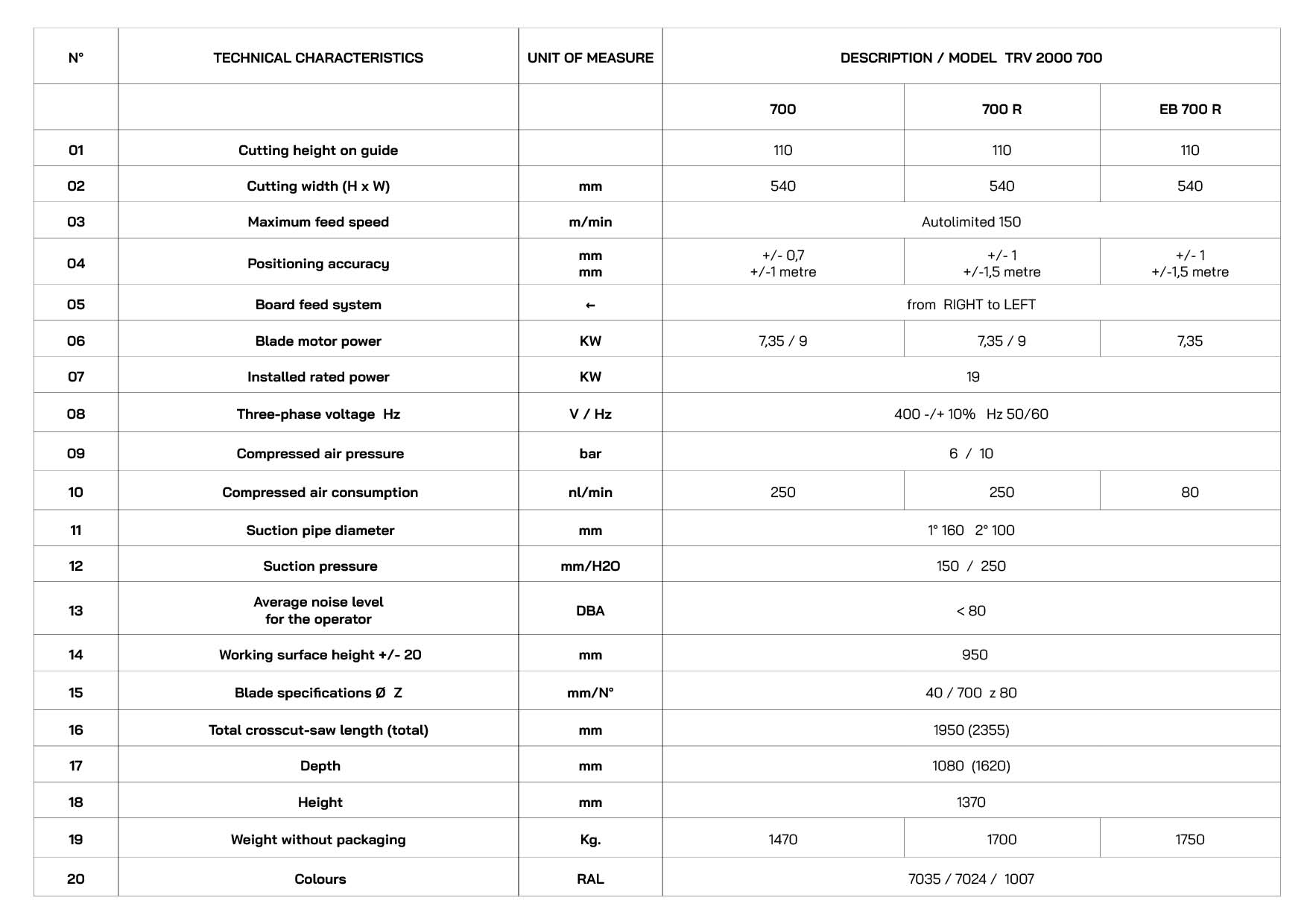

BELT FEEDING OPTIMIZING CROSSCUT SAW – TRV 2000 BLADE Ø 700

THE OPTIMIZER THAT SOLVES SAWMILL CHALLENGES

Designed to handle the intense pace of primary processing in sawmills, the TRV 2000 700 represents the pinnacle of Cursal technology: automatic, continuous-cycle optimizers with belt feed for inline side-board recovery from log breakdown, or roller feed for selecting quality in dry, high-grade hardwoods and defected boards.

Engineered to maximize speed, yield, and precision on both rough and edged boards.

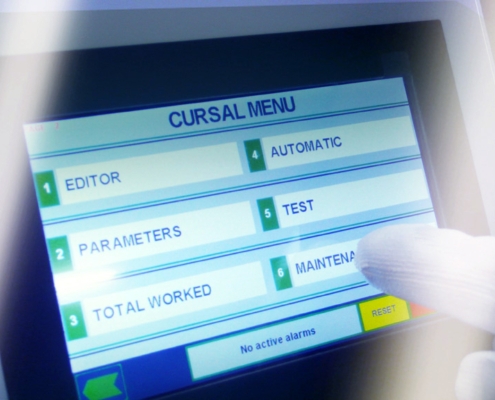

INTEGRATED INTELLIGENCE

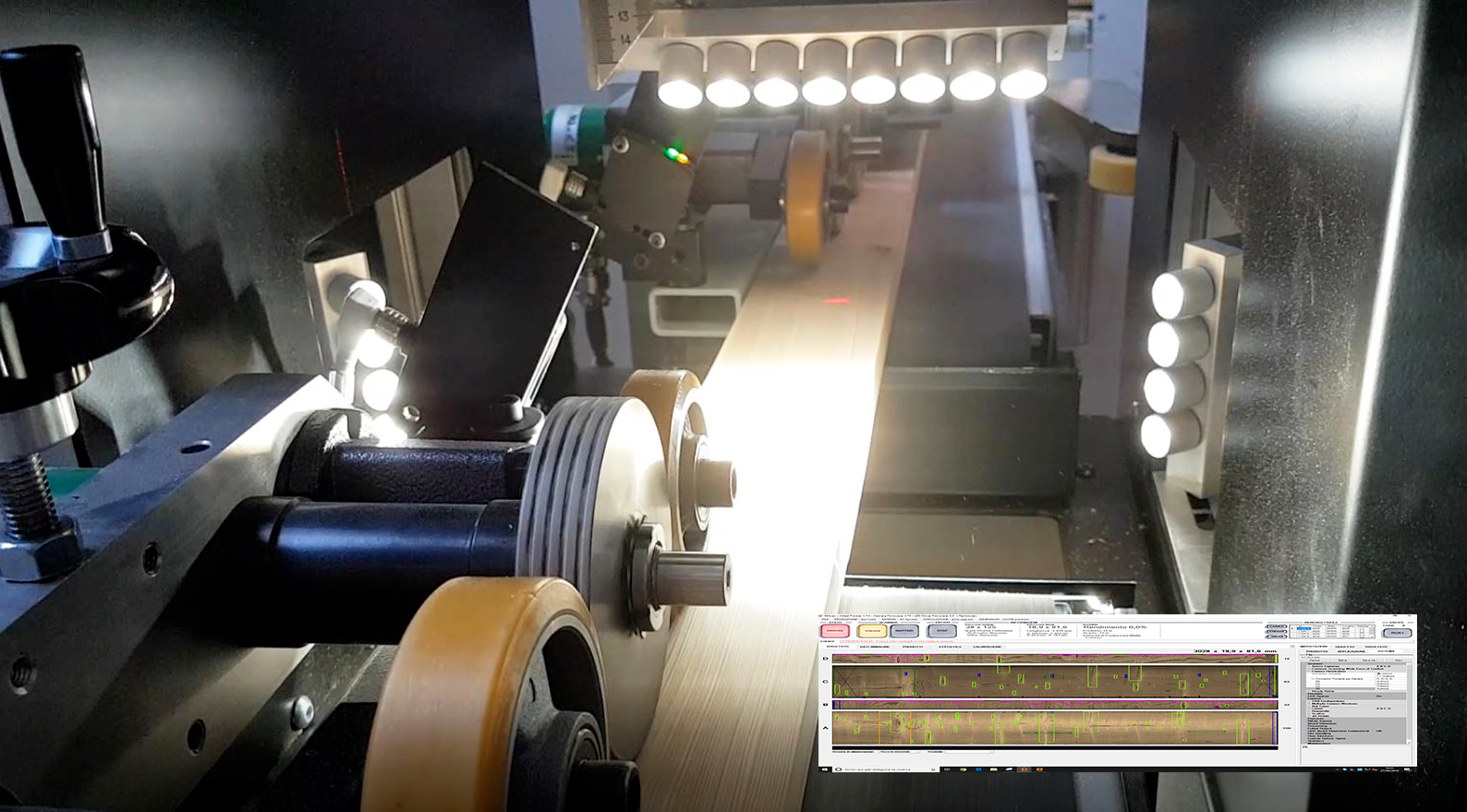

At the core of the system is Cursal’s software, capable of reading, analyzing, and optimizing every board before cutting.

A dedicated camera detects luminescent chalk marks and, using pre-set algorithms, selects the optimal cutting strategy—by value, quantity, or yield.

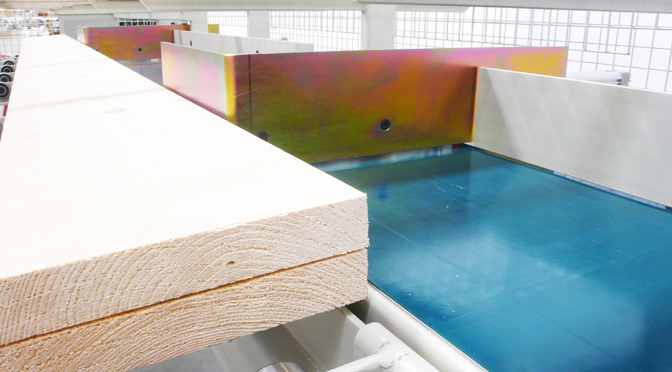

CONTINUOUS PRODUCTION WITHOUT BOTTLENECKS

TRV 2000 machines work inline without stops or buffer zones, even with irregular or variable loads.

Compatible with both new and existing systems (log breakdown lines, movable gang saws, planers, scanners), they are the operational core of fully automated industrial lines.

ADVANCED FUNCTIONS

The TRV 2000 benefits from software perfected over thousands of installations on premium wood optimizing lines: 128 simultaneous dimension groups, cutting modes by defect, mark, list, or job order, automatic table switching, data export in Excel format, USB, Ethernet, RS 232/485 interfaces, real-time cycle simulation and control, intelligent end-of-batch auto stops, and more.

CURSAL INDUSTRIAL ENGINEERING

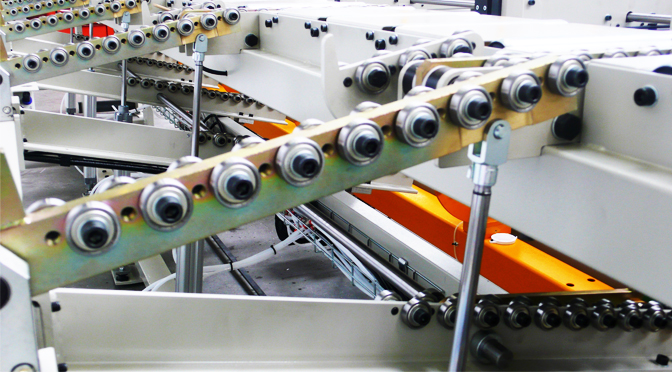

Electronic vertical blade movement

Upper carriage with independent, adjustable wheels

Full safety guards, anti-intrusion sensors, and pressurized control cabinet

Compact modular frame, ideal for customized layouts

Speeds up to 150 m/min, self-limited

THE RESULT?

Less waste, higher yield, reduced time, full traceability.

TRV 2000 is much more than a crosscut saw:

it’s an investment that turns into real, daily operating margin.

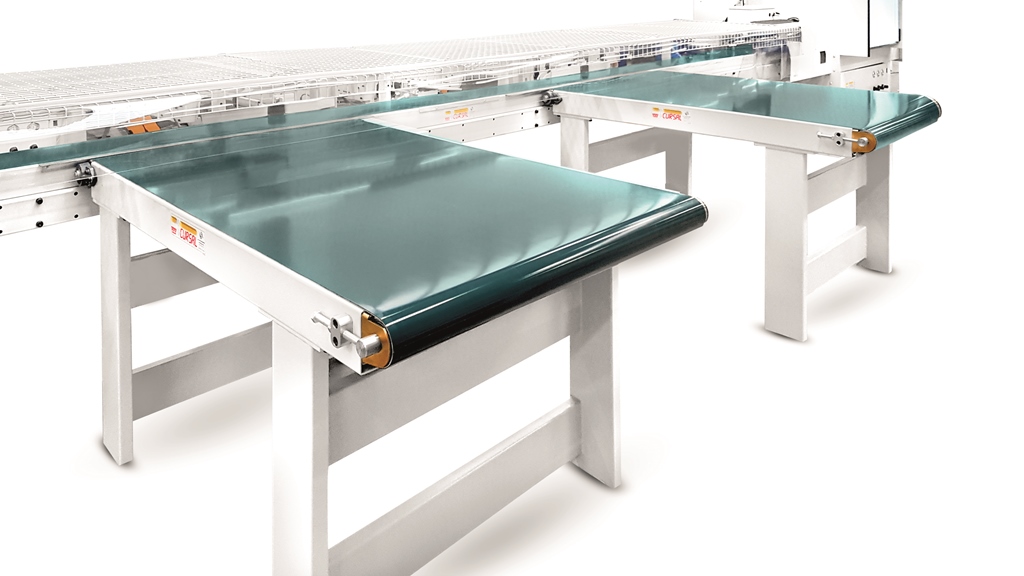

TRV 2000 700 with BELT FEED TOTAL GRIP, CONSISTENT YIELD

When the wood is irregular, curved, or unedged, you need a machine that keeps control without missing a beat.

The TRV 2000 with belt feed is designed for exactly that: it ensures continuous flow even with complex boards.

Especially suitable for inline processing with log breakdown lines for side-board recovery.

TECHNOLOGY THAT GRIPS AND GUIDES

The motorised cnc belt works in synergy with adaptive pneumatic wheels to guarantee constant grip, keeping the board firmly in position throughout the cutting process.

REACTIVE INTELLIGENCE, OPTIMIZED CUTTING

The system reads manually applied reference marks and calculates in real time the best cutting solution:

– by value

– by quantity

– by quality

– or in combined mode

All managed by Cursal software, configurable according to the production line’s goals.

Ready for integration with Cursal’s LIDAR scanner, which replaces manual marking.

EB VERSION – HIGH SPEED

High-performance setup with:

– servo-motor blade movement for fast cutting

– inline handling for lengths up to 6,300 mm

– self-adjusting components and integrated safety features

A VALUABLE ALLY, EVERY DAY

The TRV 2000 with belt feed never stops: it optimizes, speeds up, reduces waste, and boosts the entire line.

An investment that turns every meter of wood into measurable value.