BELT FEEDING OPTIMIZING CROSSCUT SAW – TRV 2700 BLADE Ø500-550

CURSAL BELT FEED SYSTEM INTELLIGENT GUIDANCE FOR MAXIMUM YIELD

– progressive control

– dynamic precision

– full synchronization

In the world of industrial cross-cutting, speed alone is not enough.

To achieve consistent, reliable results, you need continuous traction, precision control, and seamless mechanical-electronic integration.

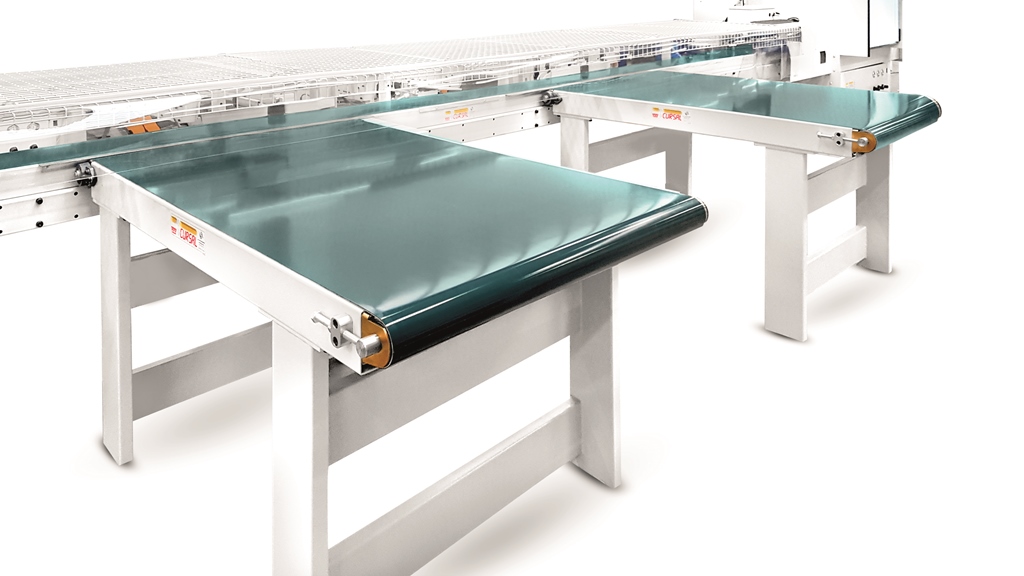

The CURSAL belt feed system goes beyond mere positioning:

it actively guides each board through the cutting cycle, maintaining alignment, reducing vibration, and optimizing path even at high speeds.

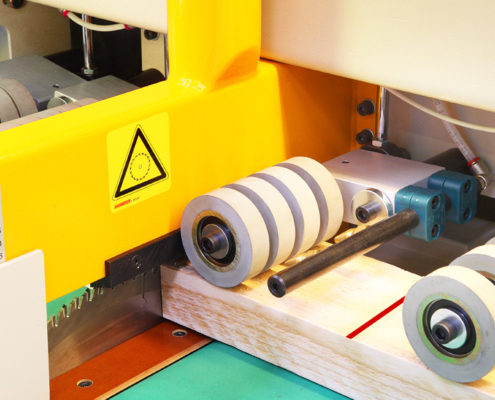

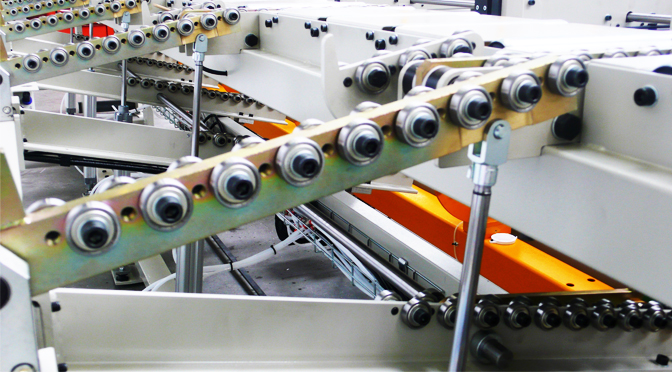

No engaging parts – avoiding jams, abnormal wear, and wood surface damage

Rubber and ground wheels with calibrated pressure have a short distance between axles to ensure uniform feed with synchronized numerical control

Fully synchronized CNC control

This configuration turns the CURSAL feed belt into a true intelligent mechanical interface, dynamically adapting to curvature, deformation, and moisture content of the material.

Smart acceleration without board slippage

Base cutting unit with dual pneumatic cylinders

Enables fast, accurate cycles, significantly increasing system efficiency.

Result: More linear meters processed, less waste.

PRACTICAL TECHNOLOGY FOR INDUSTRIAL WOOD PRODUCTION

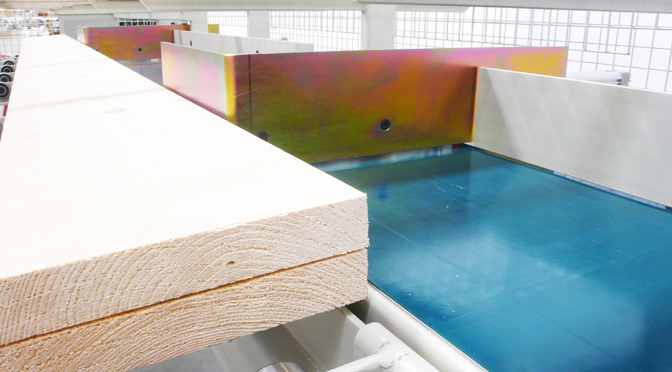

At the heart of modern industry—where quality and speed must coexist—the TRV CURSAL line offers a concrete solution.

It combines robust mechanics, intelligent software, and 24/7 continuous operation.

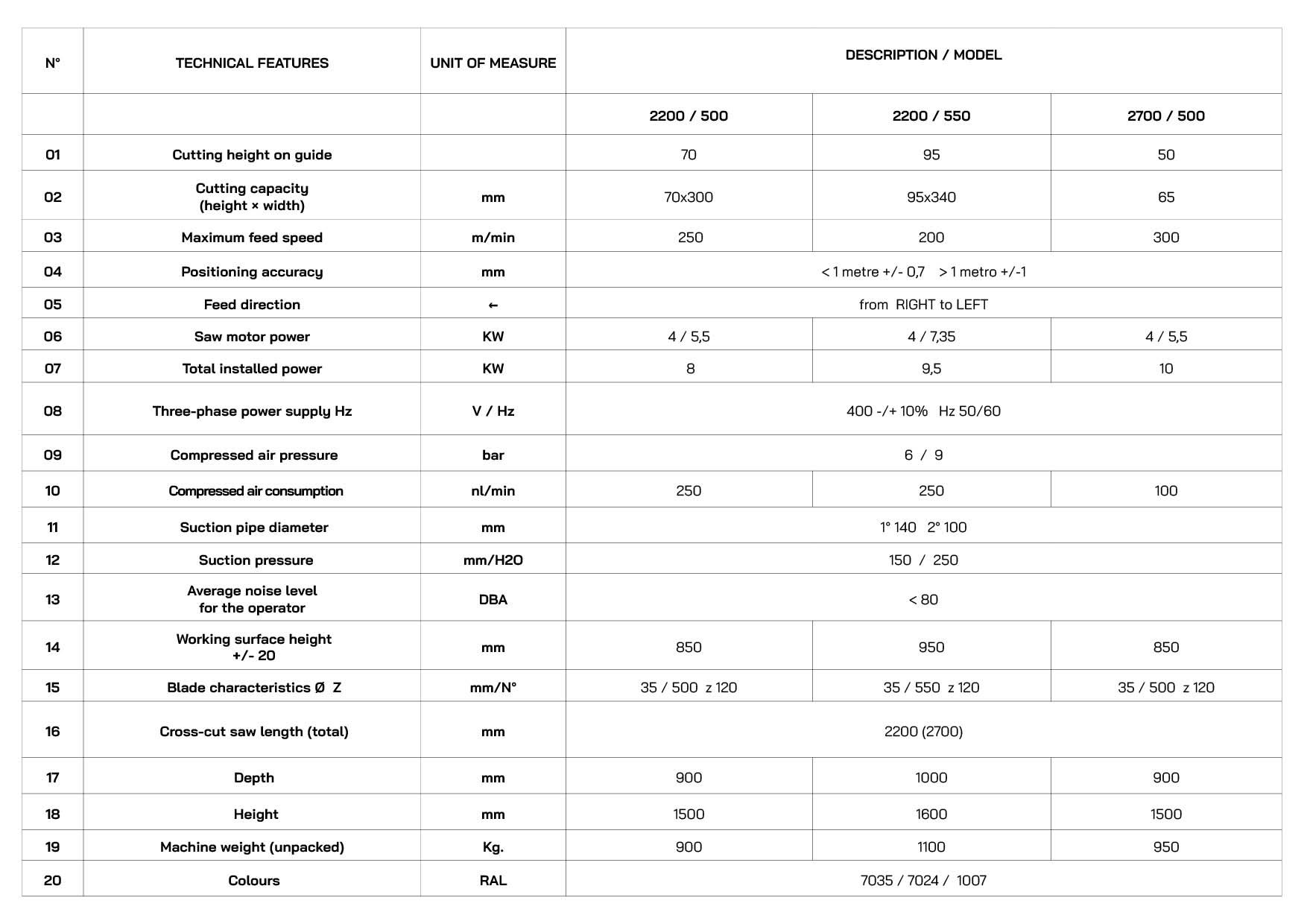

Built on the same technological platform, the TRV 2200E and TRV 2700EB offer two complementary approaches adaptable to a wide range of production requirements.

TRV 2700EB – SPEED & CONTROL FOR HIGH VOLUME

Ideal for intensive production and heterogeneous wood.

Equipped with a new-generation Brushless cutting system, the TRV 2700EB achieves over 400 cuts per minute.

Designed for:

– non-stop production

– complex or variable materials

– maximum efficiency with fast cycles

Active-drive technical belt with differentiated pressure, ideal even for curved or moist boards

Components engineered for maximum durability and minimal maintenance

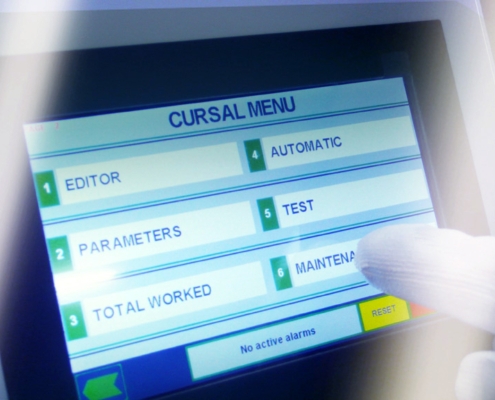

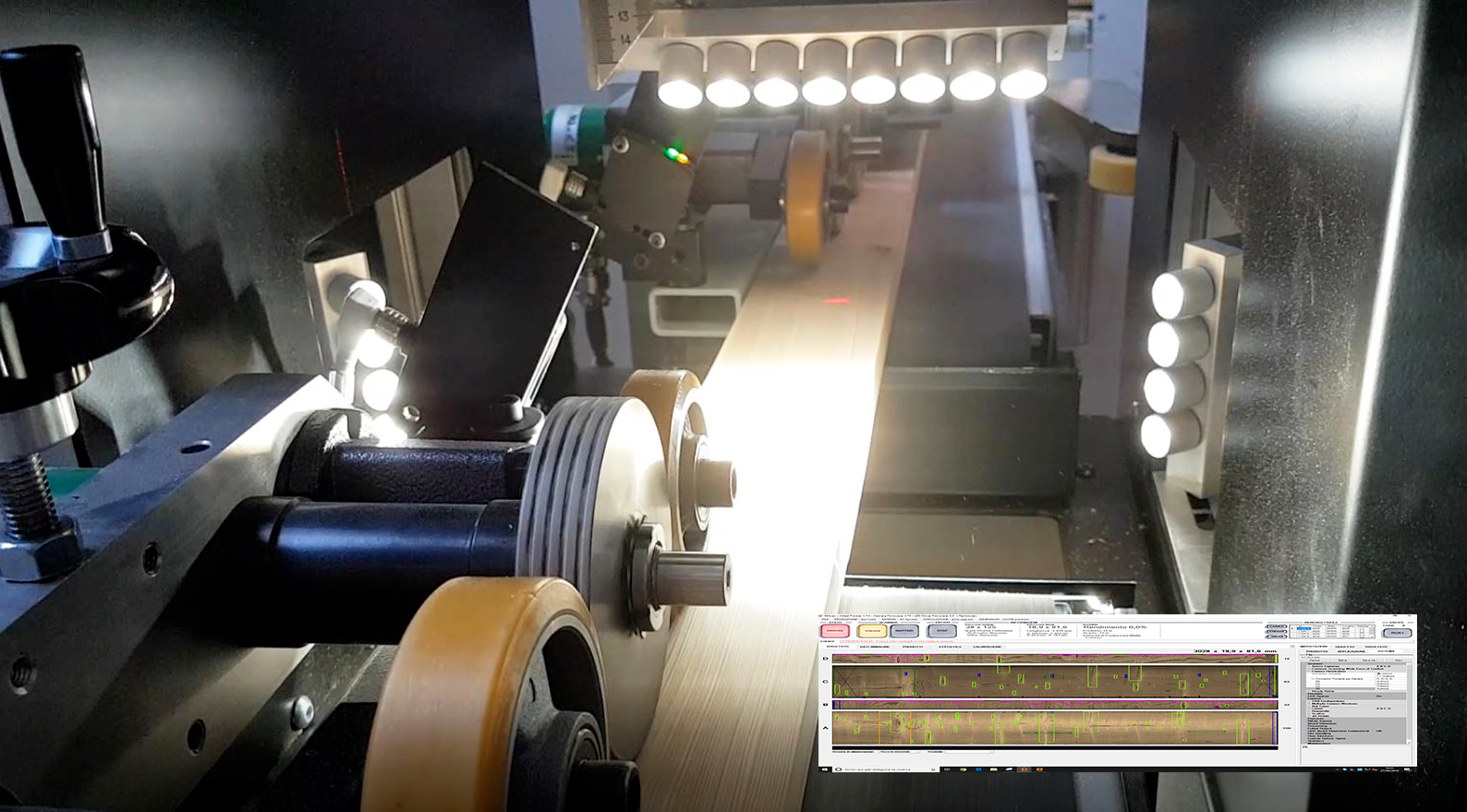

Hardware and software integrated into a single structure: analyzes, simulates, decides

The TRV system turns control into strategy

Configure over 100 cutting plans, optimize in real time, and adapt algorithms to the desired output (value, length, or quantity).

Main Functions:

– continuous optimization

– real-time simulations

– a scalable investment with guaranteed ROI

Many manufacturers install multiple TRV units in parallel, creating coordinated and modular production lines, easily integrated with scanners, loaders, markers, and sorting systems.

TRV applications throughout the entire wood production chain:

– furniture and semi-finished products

– parquet, windows, frames

– beams, laminated timber, and massive wood construction components