BELT FEEDING OPTIMIZING CROSSCUT SAW – TRV 1700 BLADE Ø 500-550-600

MAXIMUM EFFICIENCY FOR SPECIALIZED APPLICATIONS

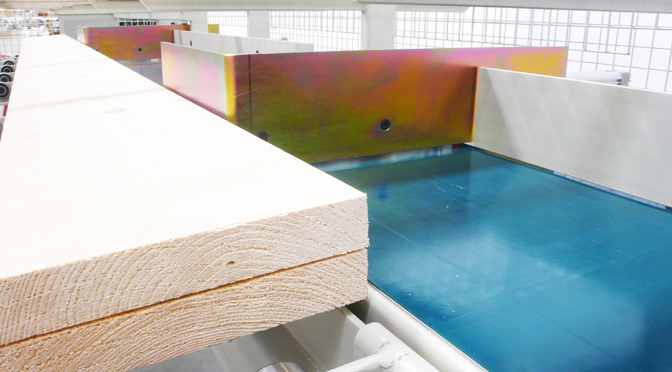

The TRV 1700 is a highly versatile optimizing crosscut saw, specifically designed for operations in line with finger jointing and moulding machines.

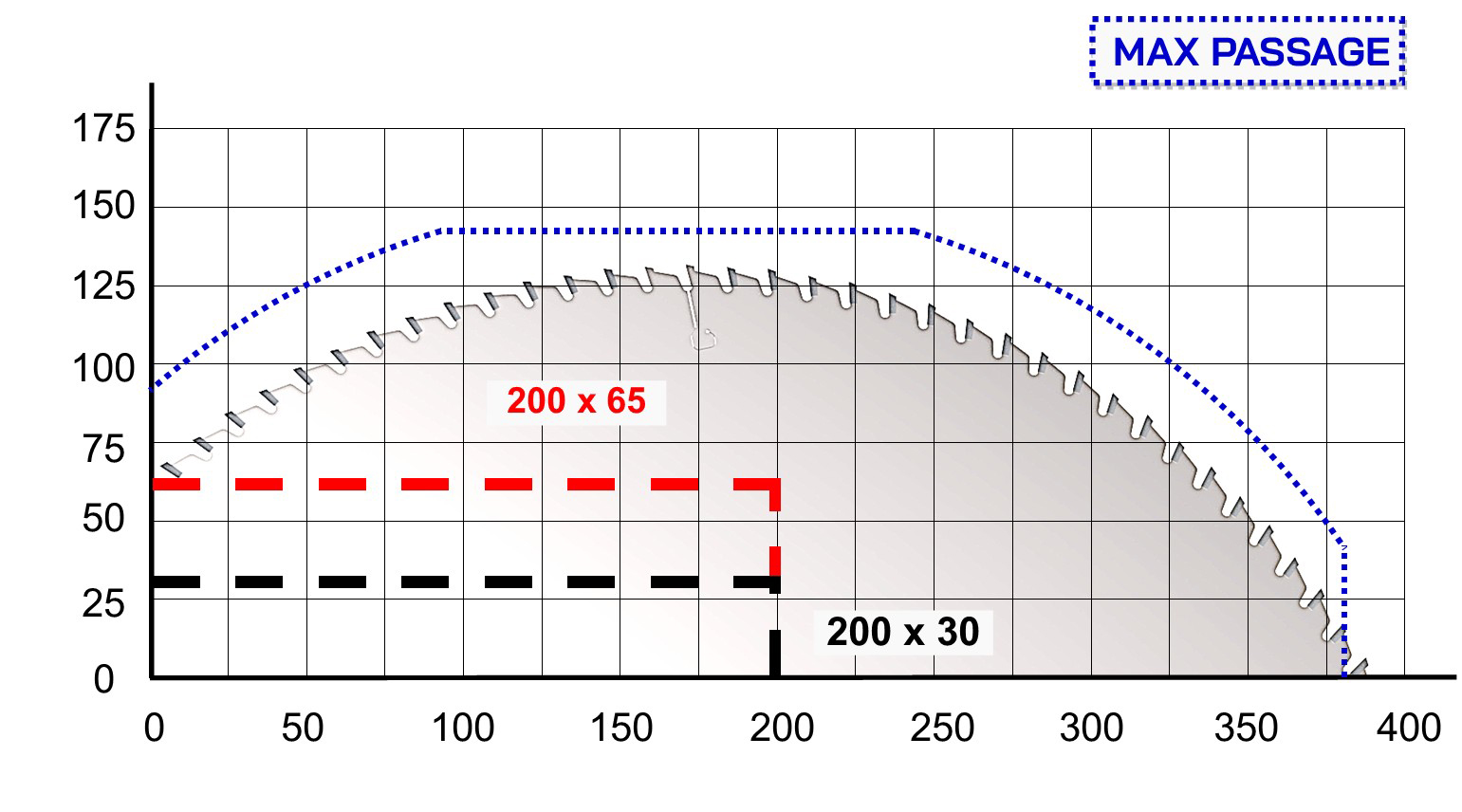

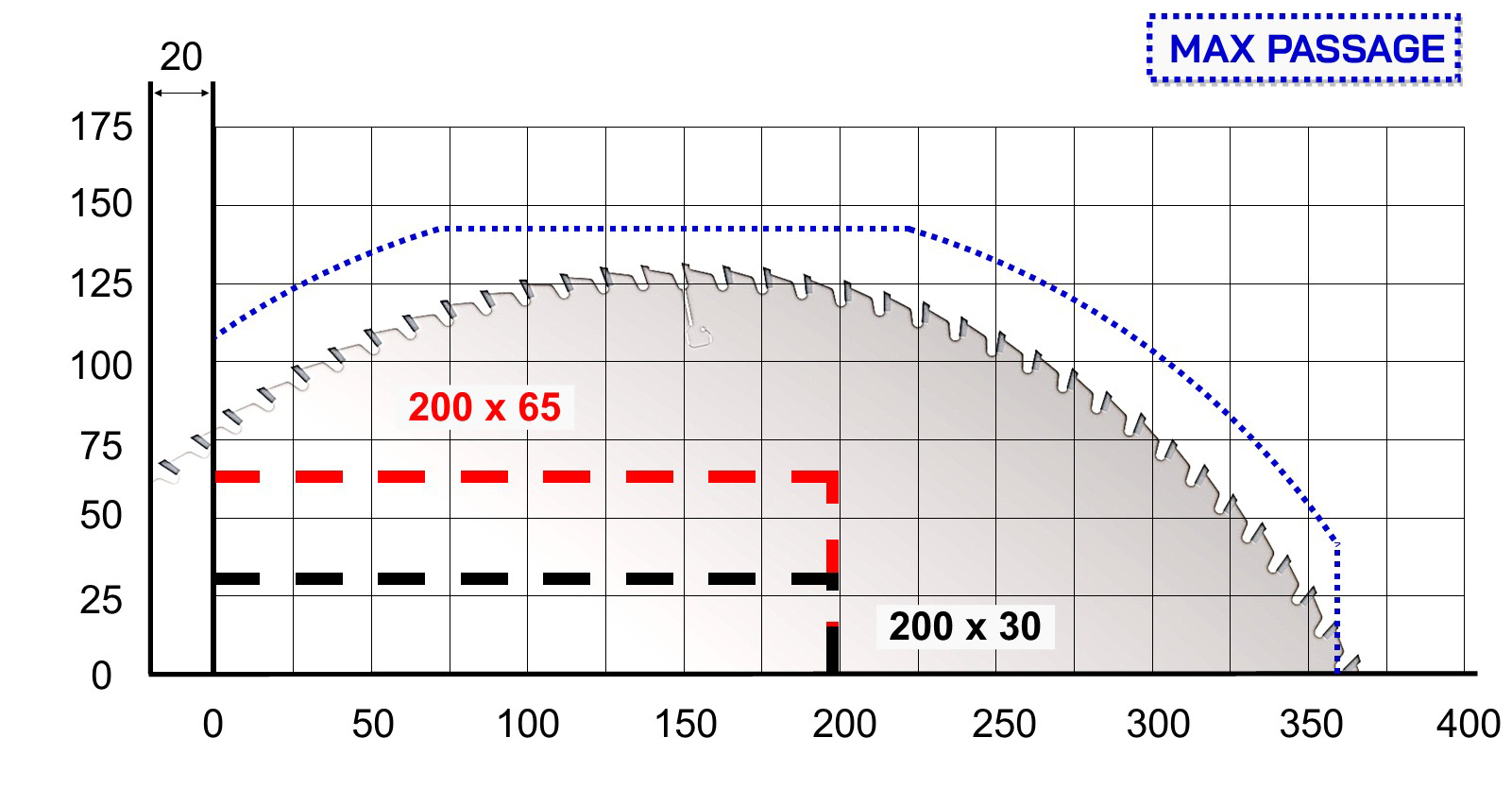

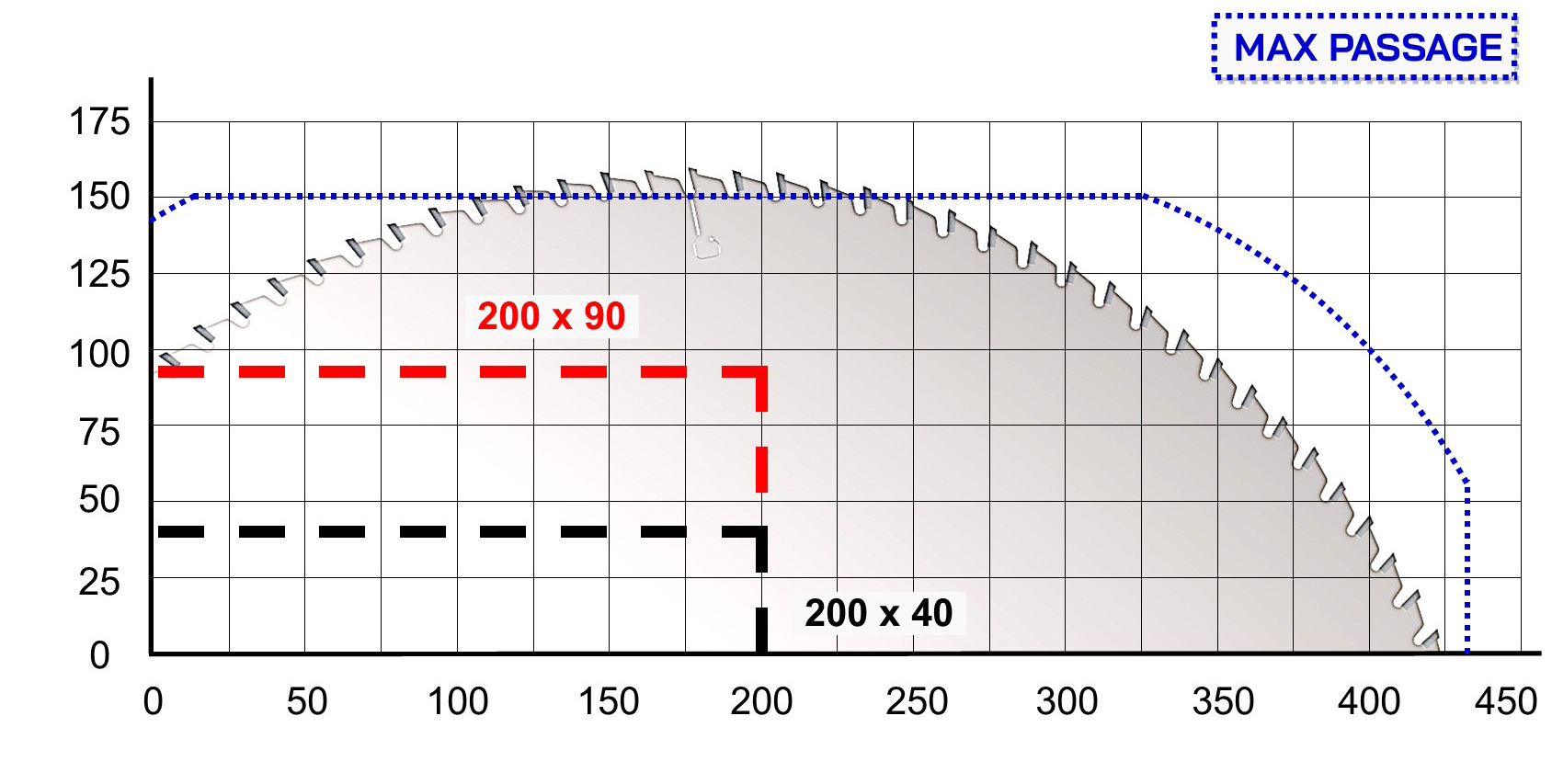

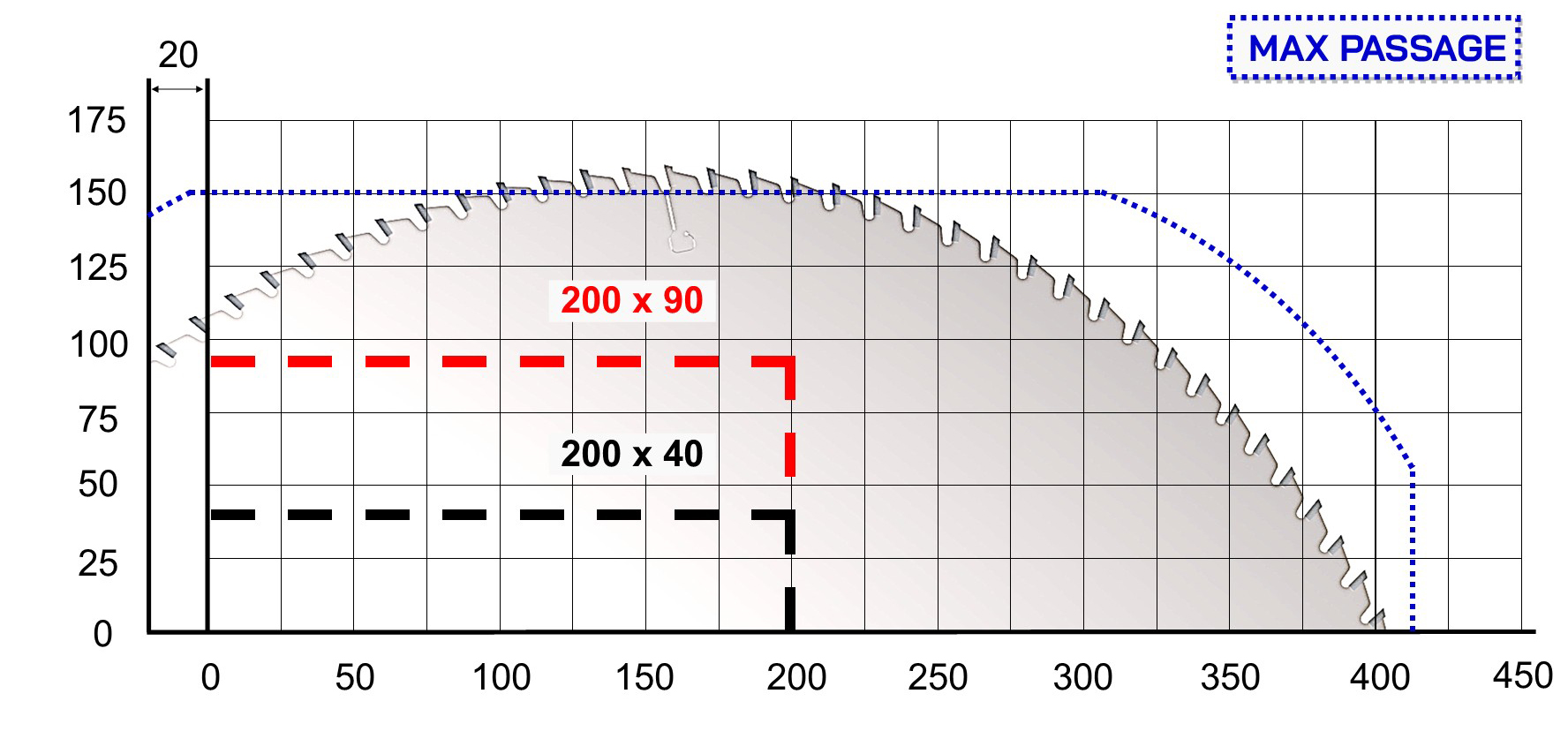

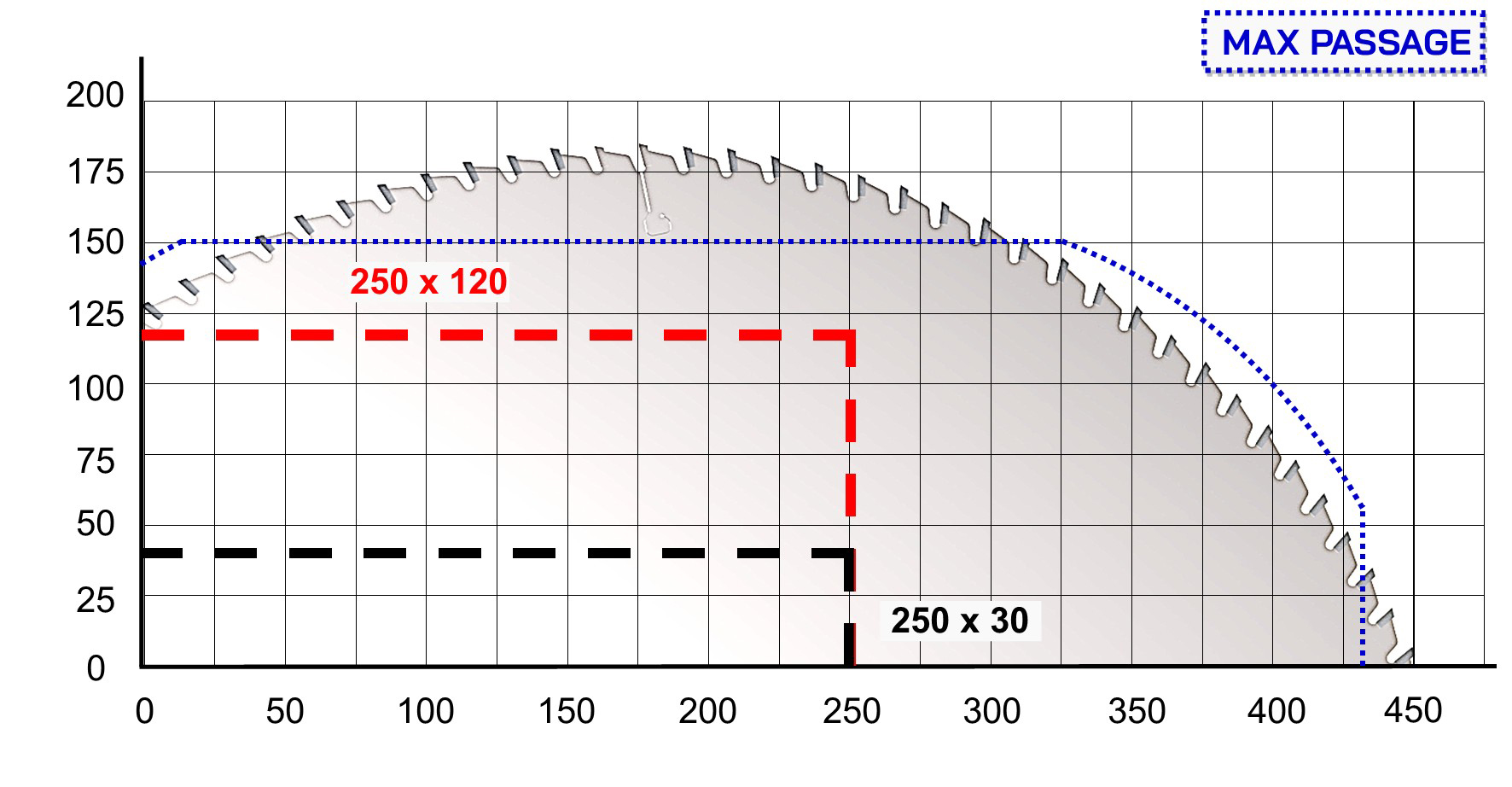

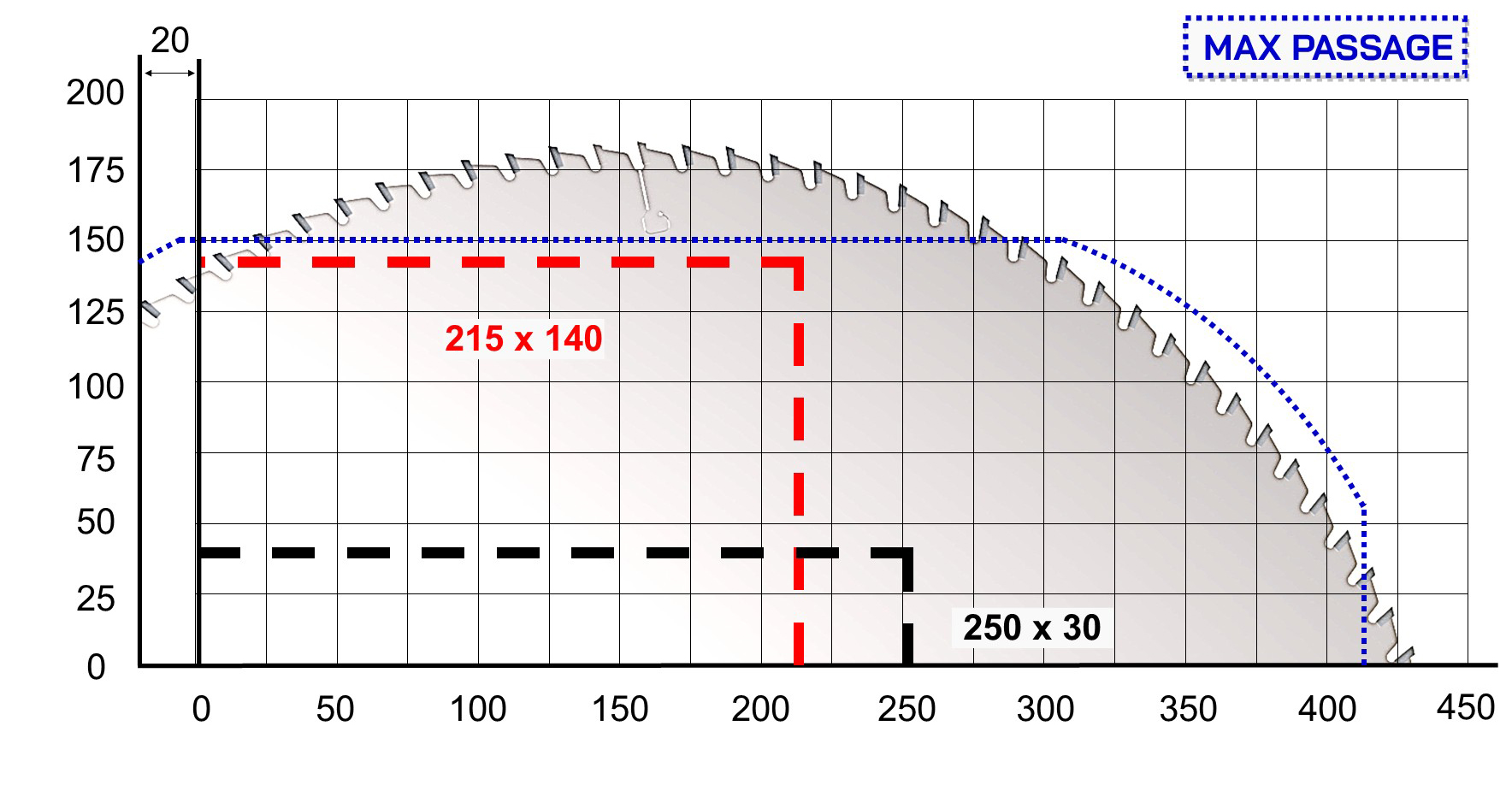

Manufactured in three configurations with blades of Ø 500, 550, and 600 mm, it is available in several versions: automatic with programmable cutting (TRV 1700A), optimized cutting (TRV 1700E – EB), and mark-based cutting only (TRV 1700S).

It is the ideal solution for quickly removing knots and defects from boards, especially when priority is given to the longest possible length (e.g., parquet) or when only defect removal is required.

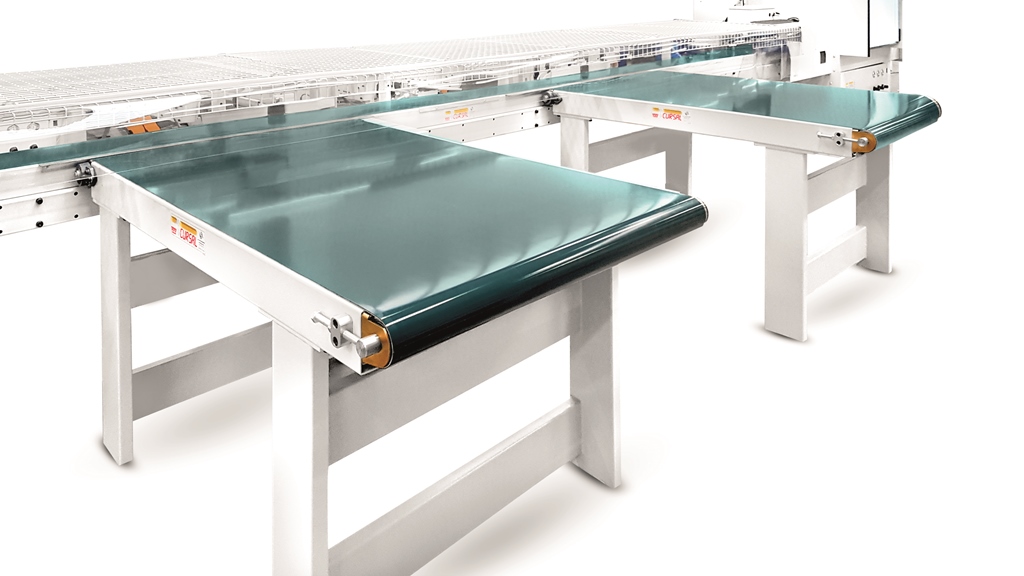

Its integration with moulders and finger jointing lines is particularly effective, thanks to Cursal’s infeed systems.

The machine can also be easily upgraded from a basic model to a fully equipped version (*see Cursal accessories section).

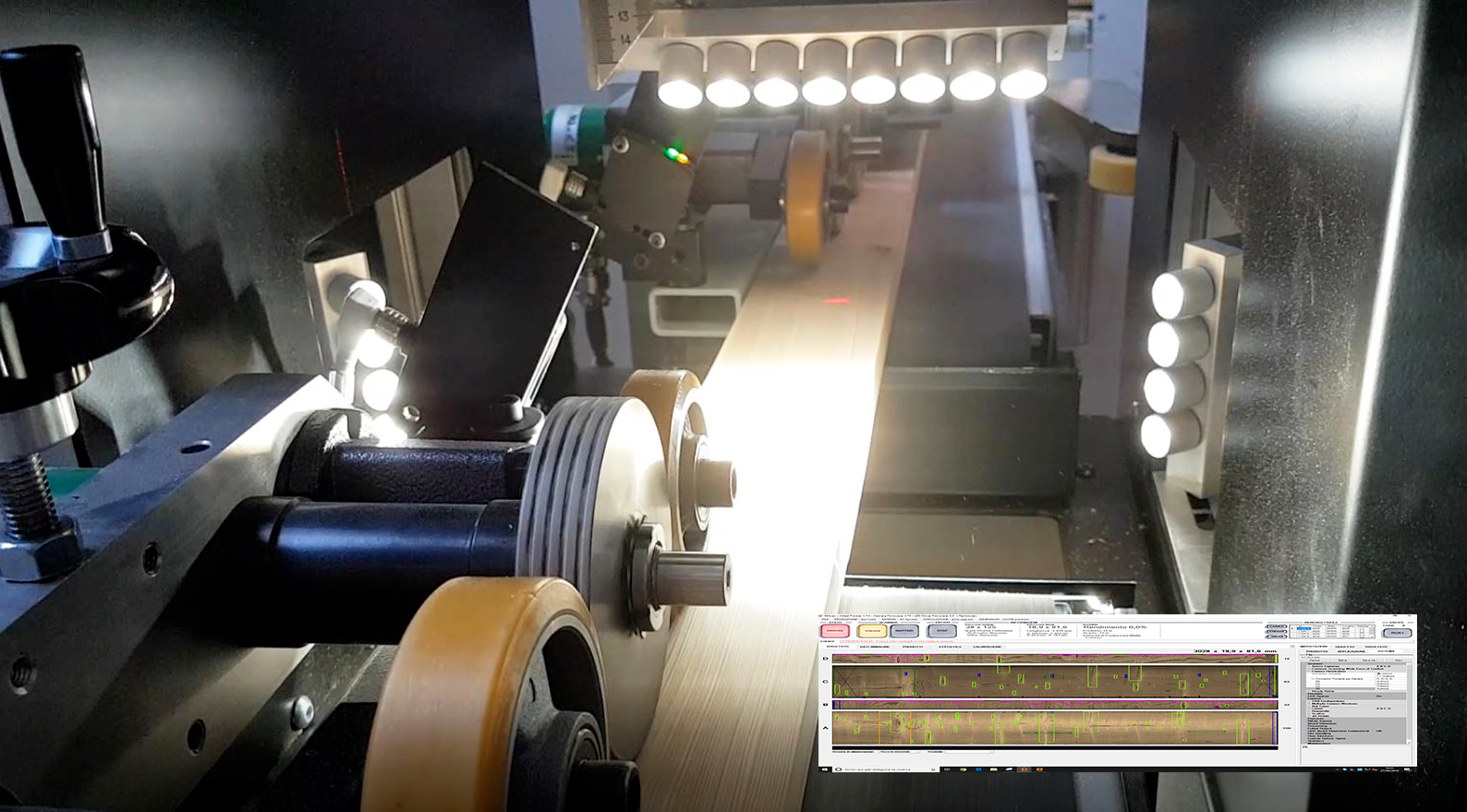

SMART TECHNOLOGY AND ROBUST BUILD QUALITY

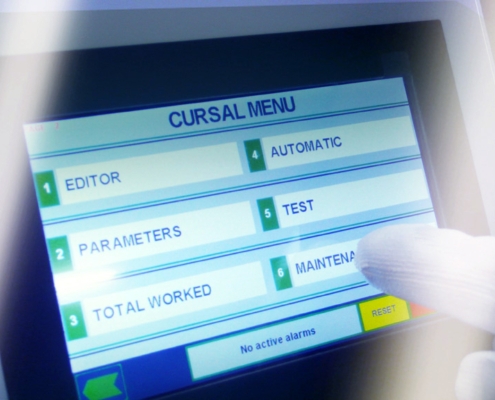

The software allows for over 100 cutting plans, configurable by width and quality.

Users can choose between various optimization modes: by commercial value, by waste reduction, by quantity, by length, or mixed mode.

It also includes optimization simulations, processed quantity tracking, and uses Cursal’s advanced optimization algorithm, which performs the entire process directly within the machine, streamlining workflow.

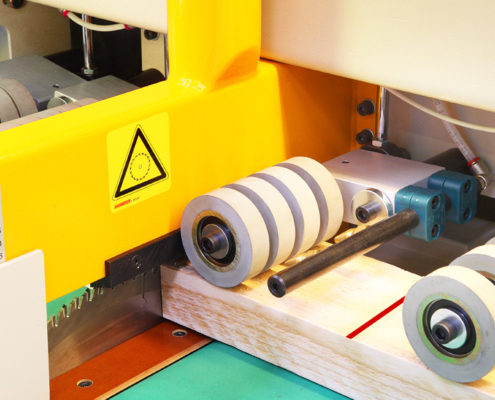

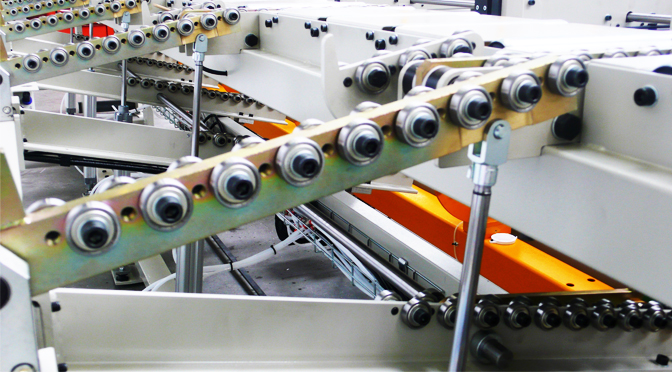

Mechanically, the TRV 1700 features a proven belt feed system without any feeding elements.

It includes anti-slip rubber pressure wheels, heavy-duty clamps for securing potential splinters, and PLC-controlled silent air blowers.

These features make it suitable for various sectors: furniture components, parquet, windows and construction, laminated beams and structures, and wood recovery for finger jointing.