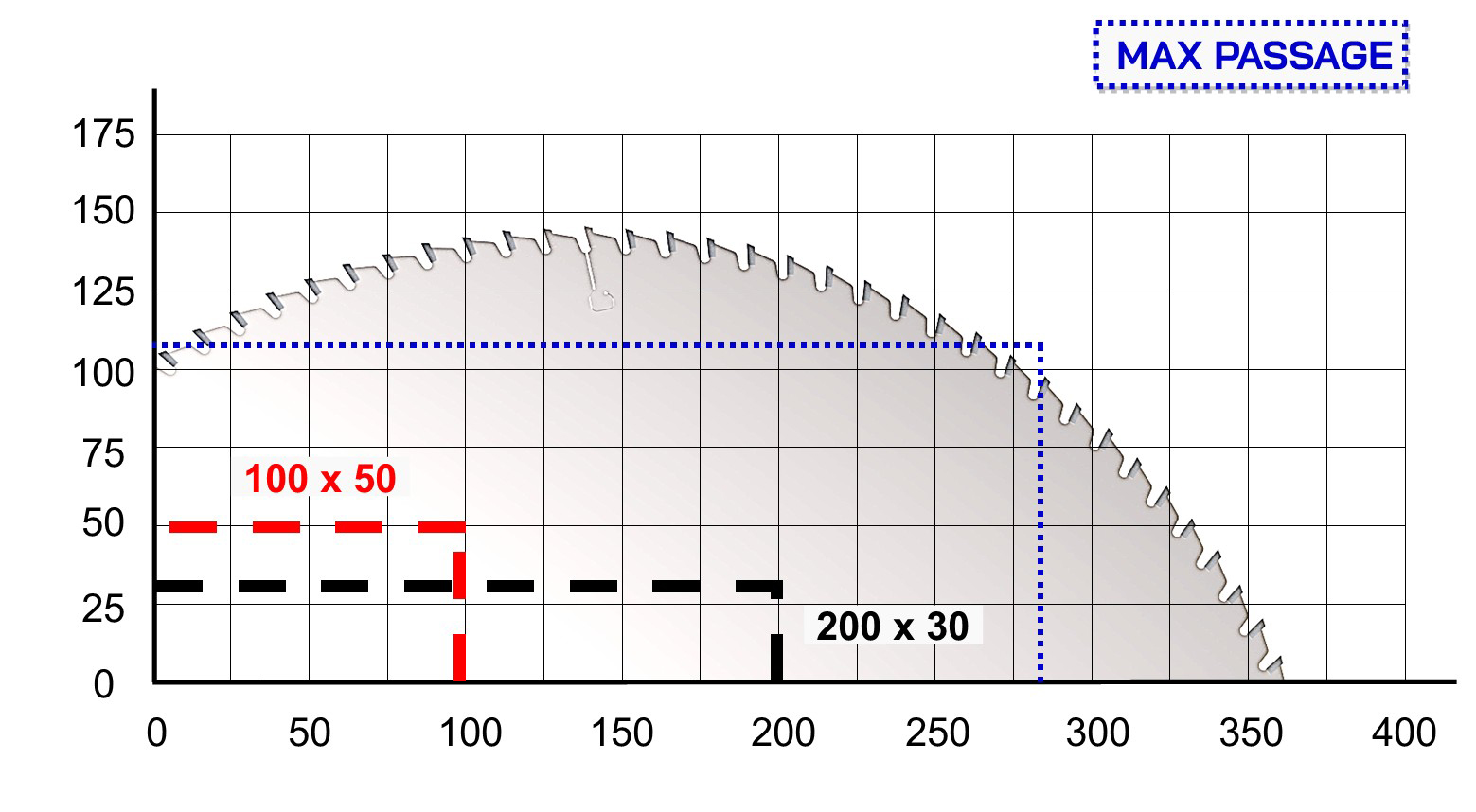

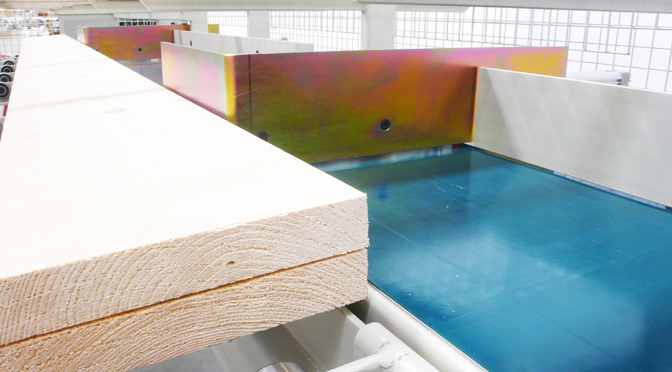

BELT FEEDING OPTIMIZING CROSSCUT SAW – TRV 1200 BLADE Ø 500

ADVANCED FEATURES FOR SMART PRODUCTION

The TRV 1200 is the ideal optimizing saw for small to medium-sized operations looking to maximize both efficiency and quality.

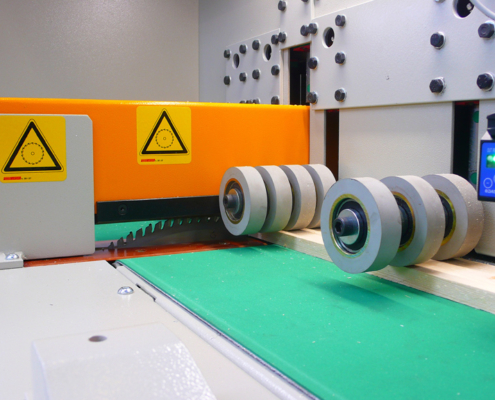

Engineered for continuous-cycle operation, it allows the cutting of single boards—whether raw or lacquered—with exceptional ease and precision.

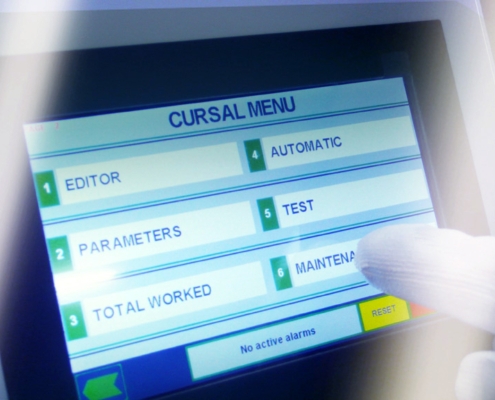

Cutting lists can be entered directly via the intuitive touch screen or recalled conveniently from the office, making setup fast and straightforward.

Once the desired optimization mode is selected—be it based on commercial value, quantity, length, waste reduction, or a mixed strategy—the machine autonomously manages every stage of the process: from board infeed and advancement to positioning, real-time data transmission, cutting, and final outfeed with automatic sorting by quality, width, and length.

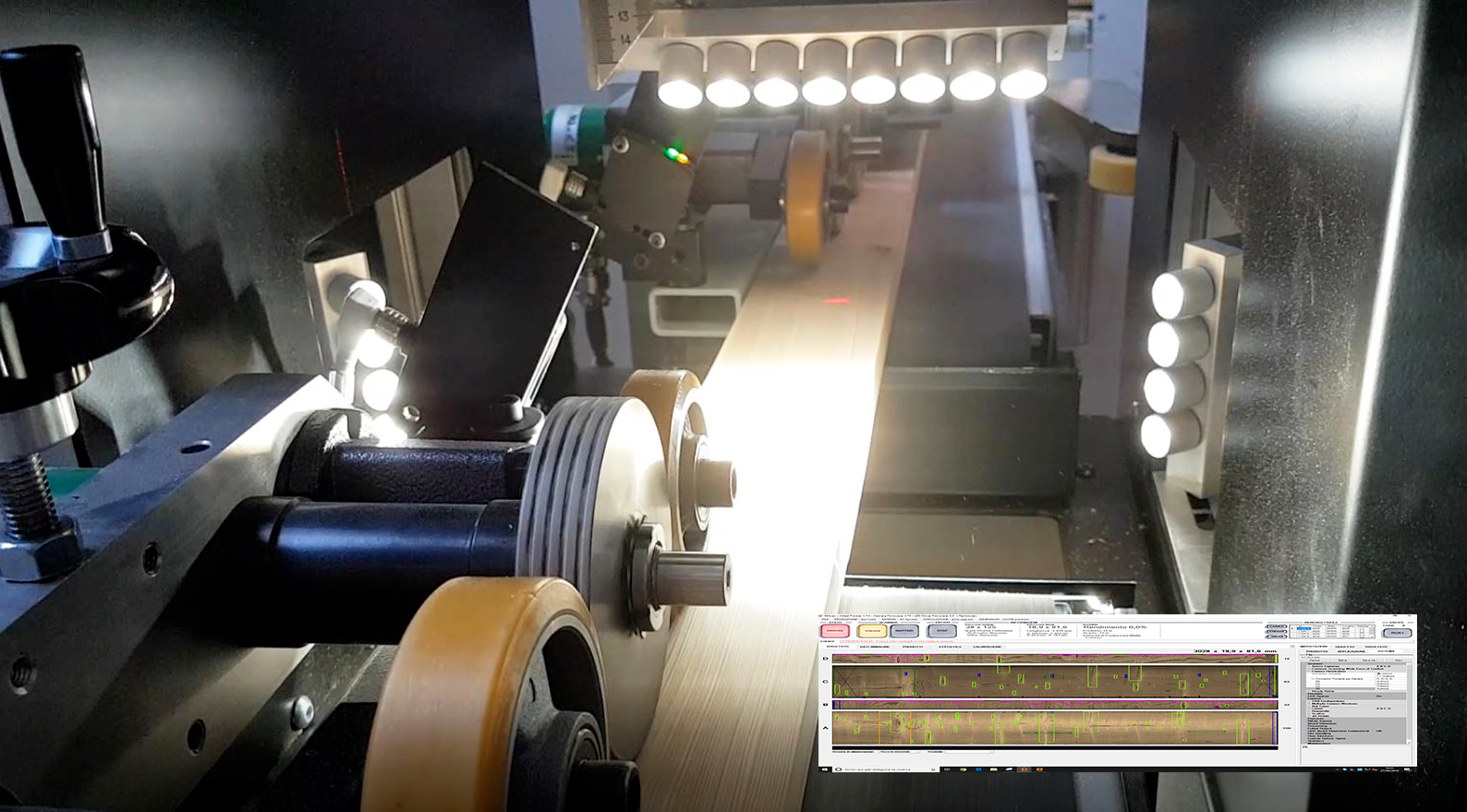

Defect detection and fixed-size processing are fully integrated, while the in-machine optimization system simplifies the workflow and optimizes valuable floor space.

HIGH PERFORMANCE AND TOTAL CONTROL

Speed, precision, and structural strength are the hallmarks of the TRV 1200.

It is the fastest in its class, with an auto-limited top speed of 195 meters per minute, driven by a Brushless servomotor that ensures consistent and controlled acceleration.

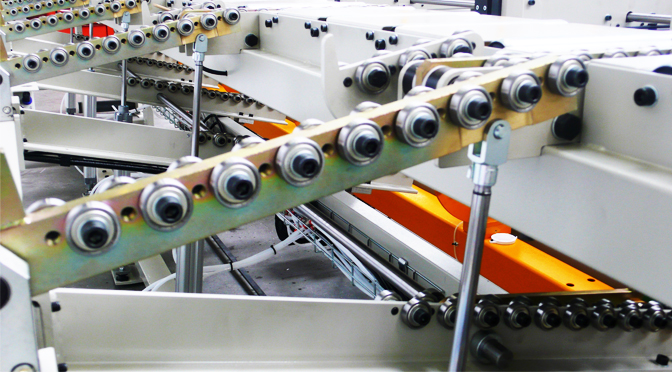

The solid, non-deformable machine frame works in synergy with an advanced table control system, featuring CNC-driven precision belts and universal pneumatic pressure wheels, ensuring high accuracy even during complex cutting operations.

The software allows the management of over one hundred cutting plans, with customizable combinations of widths and quality grades. Optimization simulation and real-time production monitoring give operators full, reliable oversight throughout the entire process.

The industrial CNC control guarantees continuous, interruption-free operation. The high-definition touch screen interface supports data import via USB and enables remote support through teleservice connectivity.

The software is user-friendly and intuitive, designed for quick learning and easy operation—even in the most demanding production workflows.

Many companies install multiple TRV units in parallel, creating coordinated, modular lines that can be seamlessly integrated with scanners, loaders, ink markers, and sorting systems.

TRV applications span the entire wood production chain:

Furniture and semi-finished products – Parquet, windows, frames – Beams, glulam, and heavy timber for structural construction.