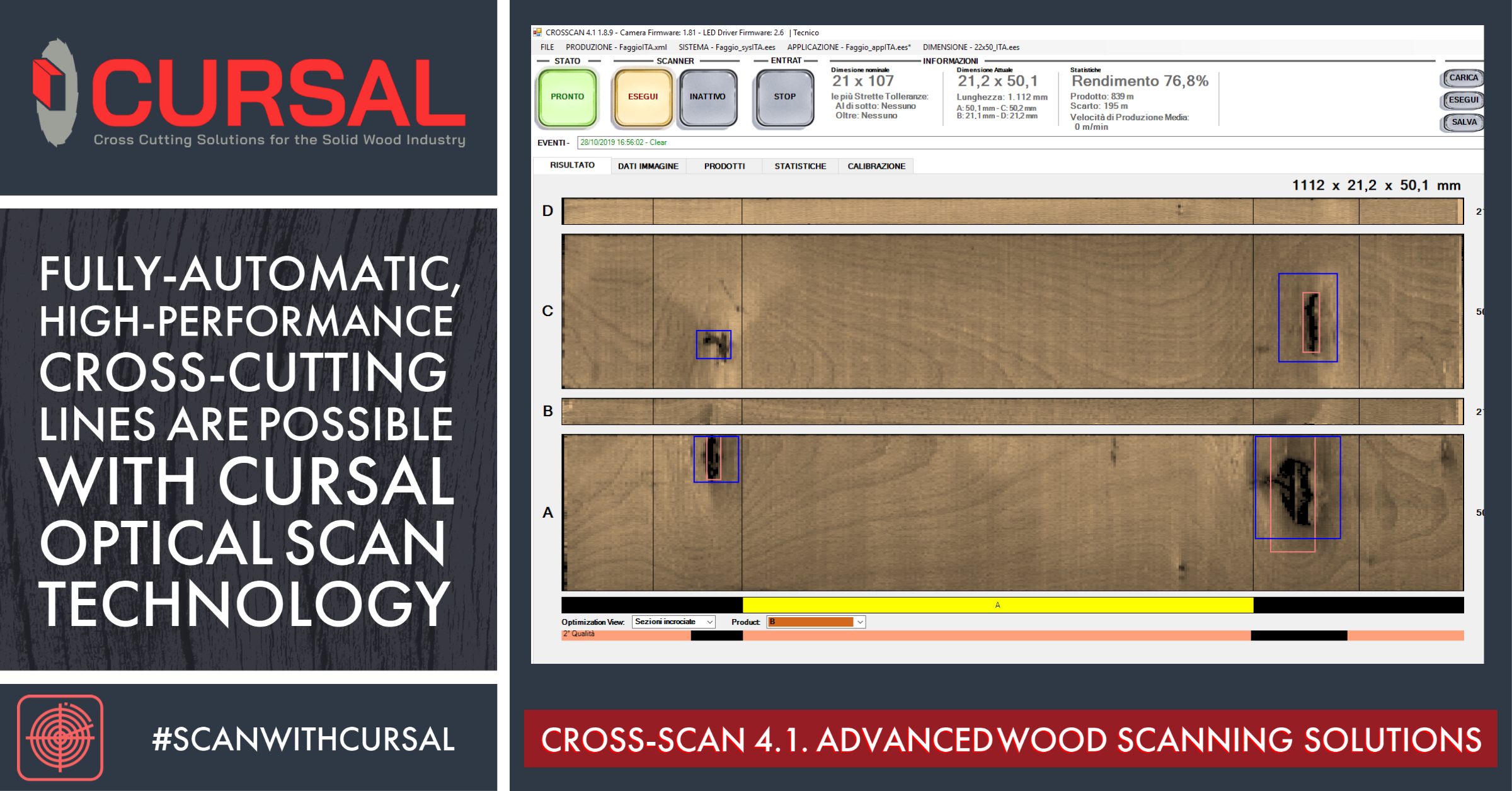

OPTICAL SCANNER QUALITY AND DEFECTS DETECTION CROSS-SCAN 4.1

TECHNOLOGICAL – INTELLIGENT – PRODUCTIVE

The scanner that scans, sorts and classifies wood the way YOU want it, consistently.

CROSS-Scan 4.1 IS THE SOLUTION FOR EXPONENTIALLY INCREASING PRODUCTION RATES WHILE MINIMISING MACHINE COSTS.

What is the OPTICAL scanner?

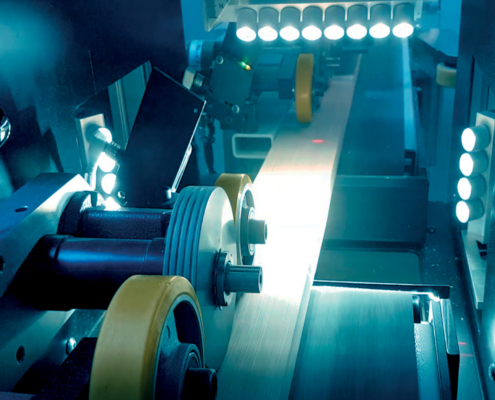

The OPTICAL INSTRUMENTATION consists of high-frequency cameras providing more than 30,000 images per second, cleverly illuminated by LEDs and stroboscopic lasers with frequencies, wavelengths, optics and programmed positioning.

Cross.scan accurately captures wood dimensions, quality and defects. The scanning process is performed by detecting defects on the 4 sides of the board, differentiating them according to set parameters.

Once the scanning has been completed, an optimisation process of the cutting list entered is used to process the best combination that will be transmitted to the NC of the cut-off/optimisation machine, allowing continuous production at very high speed.

CONSTRUCTION CHARACTERISTICS

Remote control software for online support

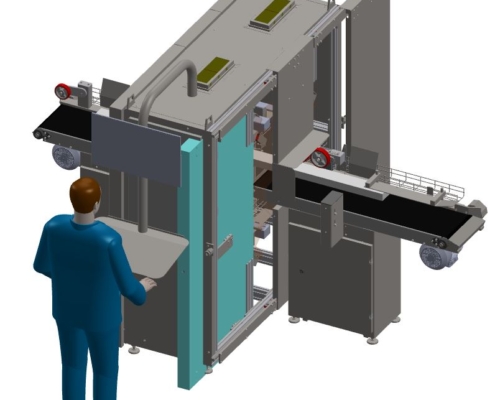

PC with LCD screen and swivelling control terminal for maximum user ergonomics

No. 4 colour cameras + No. 4 dedicated cameras for laser detection, protected in IP environment, with automatic cleaning device

Indoor environment pressurised and filtered, dust enters with difficulty

Easy lifting and transport, with anchor points for lifting with either ropes (supplied by Cursal ) or a hoist

Frame made of metal profiles and steel plates, with easy access via recirculating ball bearing sliding doors and robust, maintenance-free convenient opening

When required, monitor and keyboard on separate device

MODULAR STRUCTURE, which adapts to the options and board sizes required by the user, simplified maintenance. Adjustment of the cameras and mobile lasers is by means of actuators

The tables are fed in and taken out via a system of low-wear CNC belts:

pneumatically controlled pressure wheels, aligning guide wheels, idle wheel pressure heads, feed sequence control.

In dusty environments and with dirty boards, belts (transfer) with suction, prevent dirt from falling on the sensors.

Totally black anti-reflective interior that suppresses ambient light disturbances

DIMENSIONAL DEFECTS

Chamfers

Thickness out of tolerance

Width out of tolerance

Bark

Slots

SURFACE DEFECTS

Resin

Black resin

Knots

Black knots

Clear knots

Pink

Light blue

Radial

Marrow

Black Marrow

Graining

CROSS-SCAN 4.1 – INTELLIGENT VISION SYSTEM FOR TRV 2700EB

With up to 30,000 detections per second, CROSS-Scan is the advanced optical system that elevates the TRV 2700EB to new level of automation and precision.

Available in color versions with 2 or 4-side inspection, it analyzes each board from multiple angles, detects over 15 types of defects, classifies wood quality, generates an optimized cutting plan, and sends it to the cross-cut saw in real time.

The system is fully configurable: the operator sets the rules, and CROSS-Scan works autonomously—even on mixed batches and boards with complex geometries.

Benefits: High-frequency visual analysis – Consistent product quality – Reduced waste, increased yield – Minimal need for manual input

In development since 1998, now in its fifth generation, CROSS-Scan is fully integrated with the TRV CURSAL lines for efficient, automatic wood selection that is production-ready.

COMPACT, POWERFUL, FULLY INTEGRATED

Designed to be seamlessly integrated with loaders, unloaders, transfer systems, and with the production logic of belt-feed optimizers like the TRV 2700EB.