CROSSCUT SAWS – OPTIMIZING PUSH-FEED SYSTEMS WITH INCLINED WORKTABLE – TRG B25 BLADE Ø500 – Ø550

Compactness and precision for dynamic production

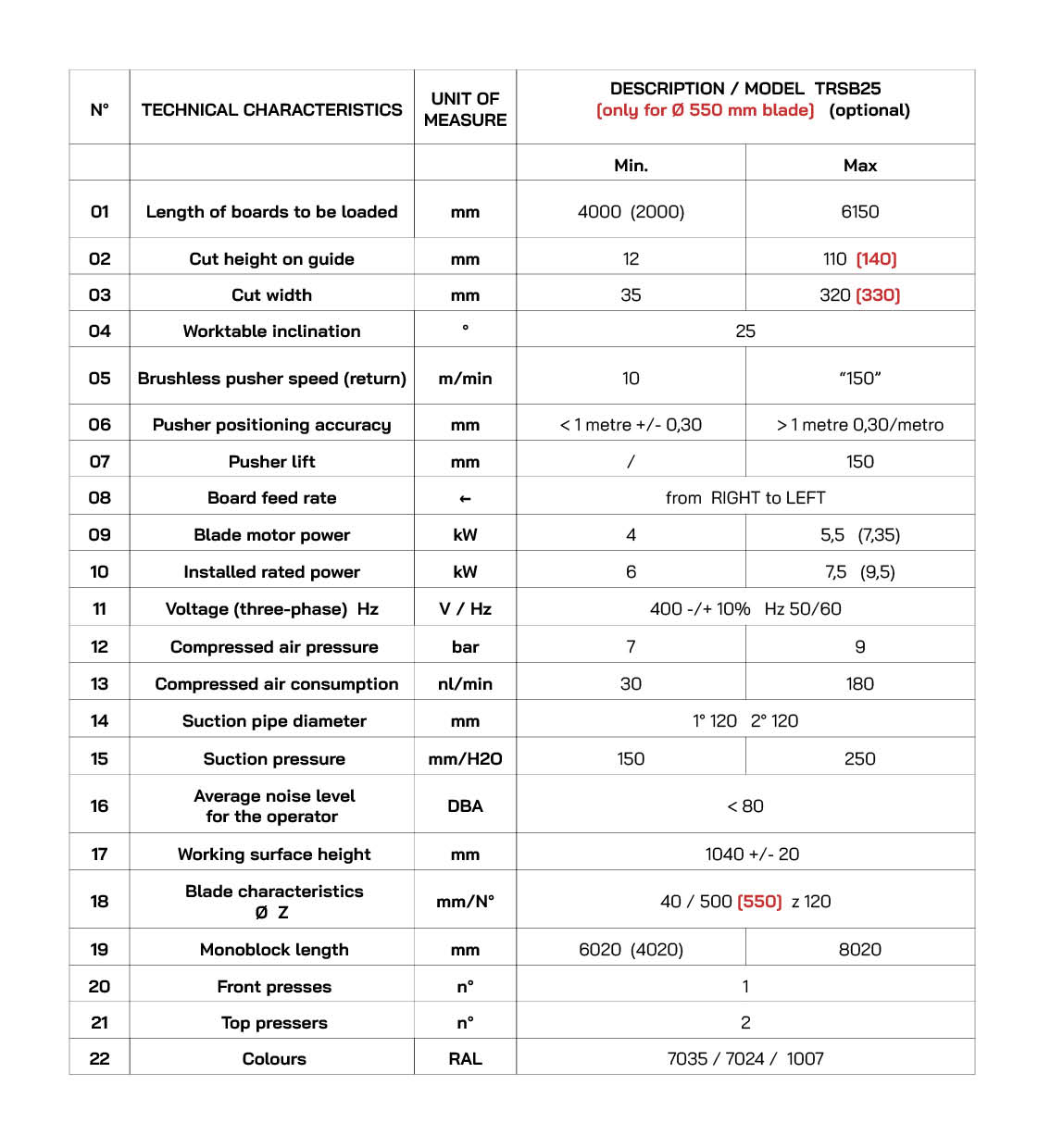

The TRS B25 is the latest Cursal solution for 90° crosscutting, developed to meet the needs of small and medium-sized productions requiring reliability, ease of use, and cost containment.

It runs the same software used on Cursal’s higher-end crosscutting saws, delivering performance refined through nearly 50 years of experience.

Compact Design, Industrial-Grade Technology

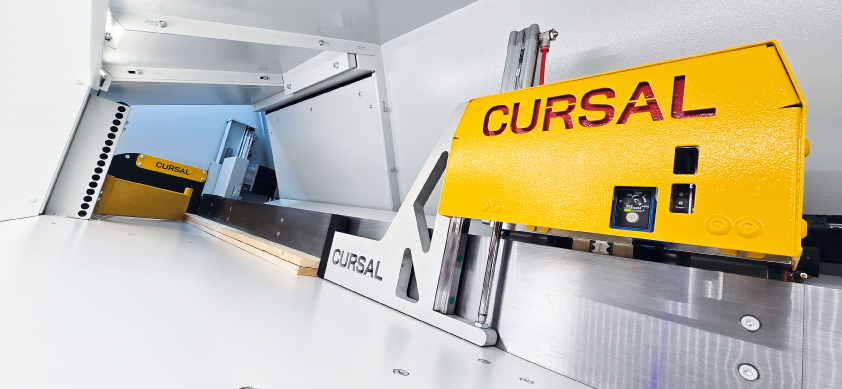

The main structure consists of a steel frame that supports all core components and accessories.

For longer working lengths, additional modular elements are available.

Currently not compatible with TRSI-series options (such as loaders, unloaders, or drilling units), the TRS B25 focuses on cost-effectiveness, structural simplification, and next-generation electronics.

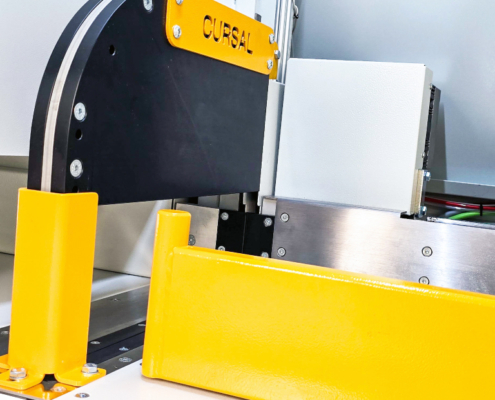

Inclined worktable: natural stability for the workpiece

The entire worktable is tilted — a smart, functional design that uses gravity to keep the workpiece perfectly aligned, even under tough operating conditions.

This results in better feed accuracy and less material waste.

Versatile and accurate across various applications

Thanks to its structural design, the TRS B25 adapts easily to a wide range of uses, including:

window and door production, custom-made furniture,

precision semi-finished parts, non-standard packaging, and joinery, especially in medium-scale production contexts.

CNC PUSH DEVICE: smooth, fast, and accurate

The feed system is equipped with brushless motors and a dual-carriage assembly running on ball-bearing linear guides, ensuring high-speed advancement up to 150 m/min while maintaining consistent positioning accuracy.

Two configurations for different production needs

The machine is available in two base versions:

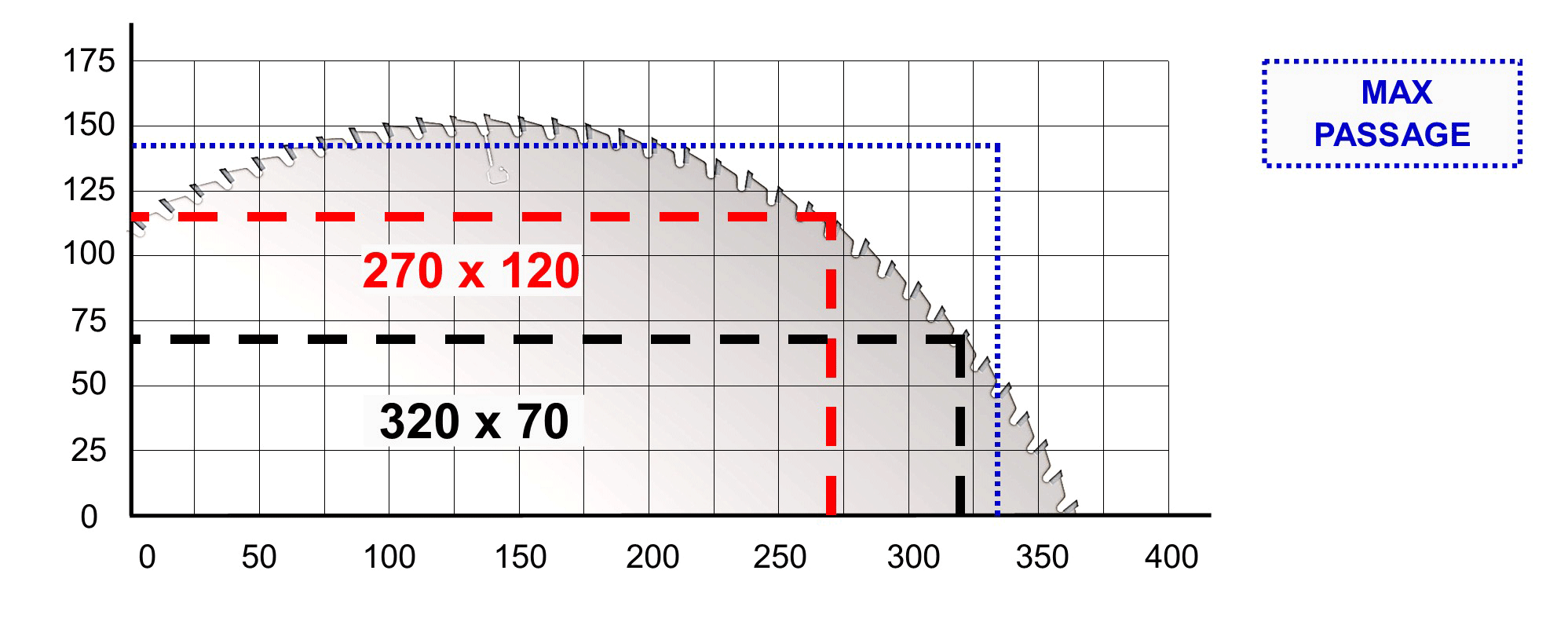

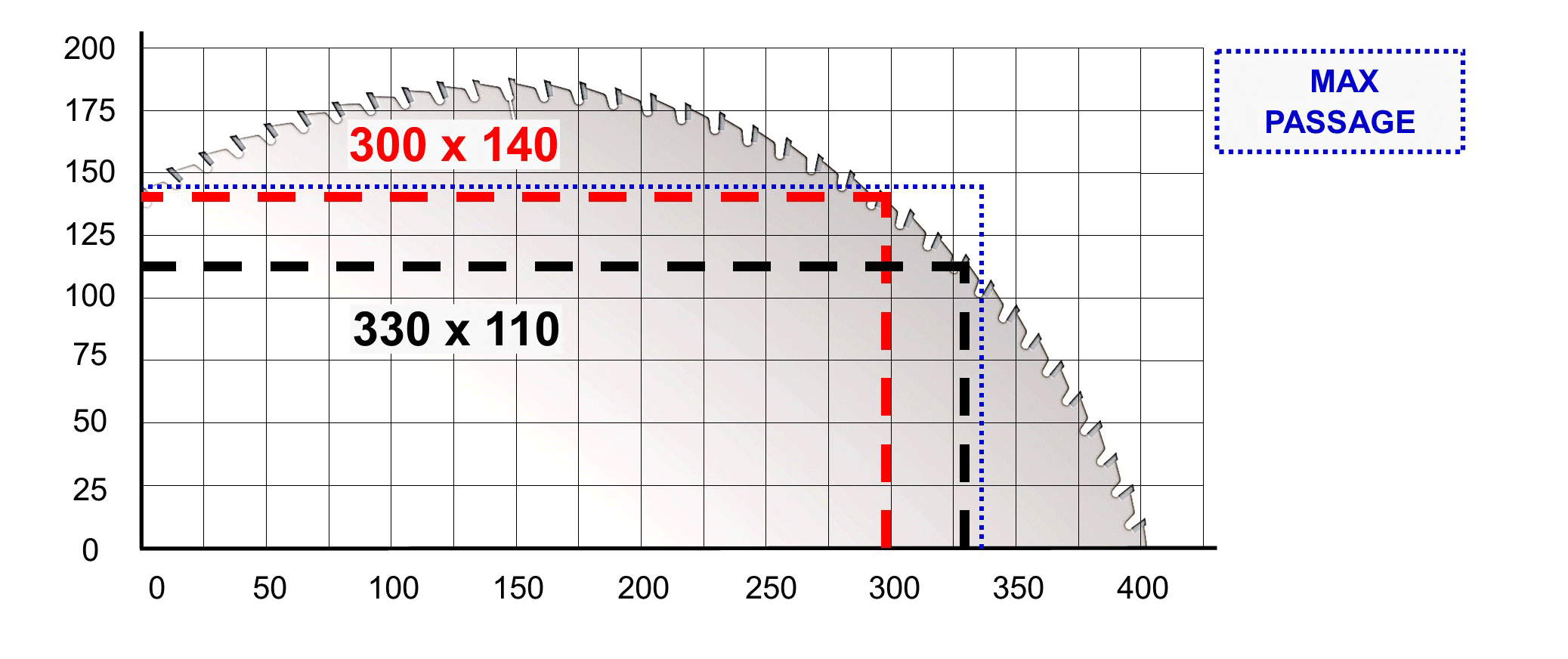

Ø 500 mm blade and Ø 550 mm blade

This allows the system to be tailored to specific application sectors and production requirements.

The TRS B25 comes EQUIPPED with a Windows-based PC, enabling all standard connectivity options required for CNC and PLC integration

SIAX is the operational software installed on the CNC computers of Cursal optimizers, designed to manage and optimize automated wood cutting.

With its intuitive touch interface, the operator can program, monitor, and customize every phase of the processing.

Upon accessing the Cursal Menu, the operator enters the heart of the system, with the following options:

Editor: create and modify orders and tables.

Work: view the machine’s status in real-time.

Parameters: customize every detail of the processing.

Test: quick checks for components and signals.

Totals: monitor real-time production.

Maintenance: diagnostics and assistance with a single click.

WHAT YOU CAN DO WITH SIAX:

Folders & Programs: organize work as you prefer.

Programs define the cutting lengths, and folders are containers for programs. You can manage both fixed and optimized sequential cuts.

Smart Optimization: program waste, prioritize cuts by value, quantity, length, or priority.

Marking with Fluorescent Chalk: helps distinguish wood qualities.

It’s also possible to recover waste for joining, ensuring precise cuts even in the presence of defects.

Processing Modes: choose between continuous processing, which optimizes recovery and reduces waste, or alternating processing, which maximizes order between good and waste.

Import/Export via USB or network: quickly and efficiently copy jobs from one machine to another.

Easy Tests and Diagnostics: check the machine’s functionality in real-time.

From signal readings to the printer, you can test all components with just a few taps.

Labels and Traceability: each piece can be identified, labeled, and tracked, ensuring full traceability of length, wood type, batch, and other information.

QUICK MENU

Cursal has never abandoned the information included in the quick menus of instruction manuals, continuing to print them next to the modern TOUCH screens on the computers.

This information remains highly used by operators for its practicality.

INTERCHANGEABILITY

The system used by Cursal guarantees all users the security of CNC computer interchangeability.

The latest generation is compatible with previous versions, even when updates are no longer available due to discontinued production.